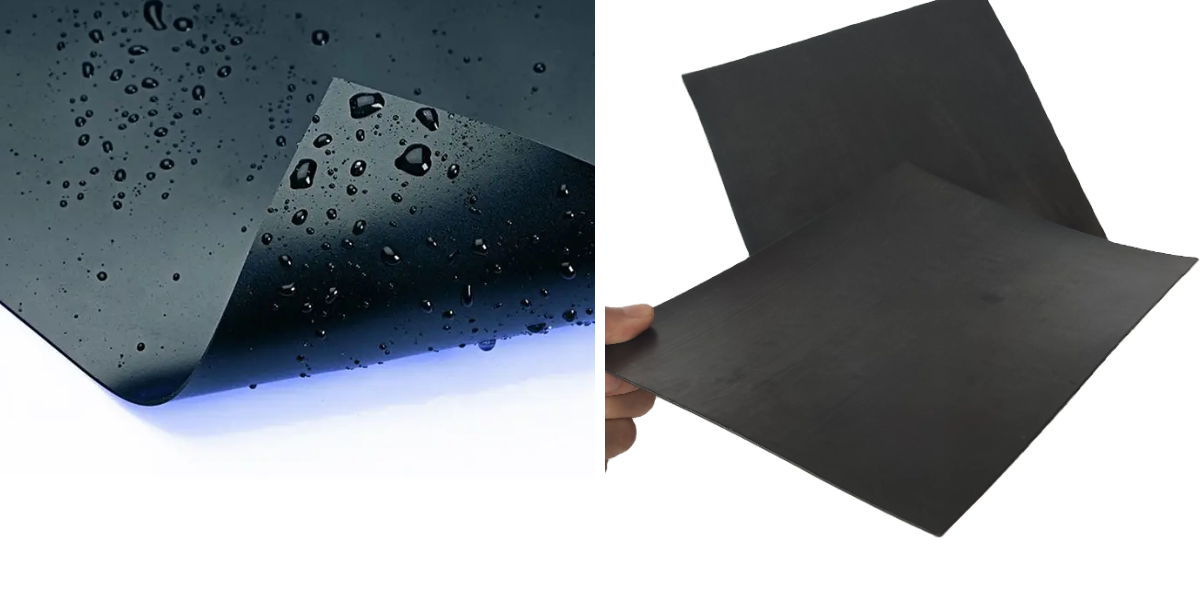

Geomembrana LDPE

High Flexibility: Greater elongation than HDPE, ideal for uneven or shifting surfaces.

Superior Waterproofing: Effective moisture barrier for moderate-stress environments.

Chemical Resistance: Withstands acids, alkalis, and mild chemicals—suitable for agriculture and landscaping.

Cold Weather Durability: Flexible at temperatures as low as -50°C, with no cracking.

Easy Installation: Lightweight, weldable, and adapts to complex shapes—saves labor.

Cost-Effective: Lower cost alternative to HDPE for light-duty uses like ponds and canals.

Product Introduction

LDPE Geomembrane (Low-Density Polyethylene Geomembrane) is a flexible, waterproof synthetic liner made from low-density polyethylene resin. It is widely used in containment, barrier, and environmental protection applications due to its unique properties.

Product Specifications

Properties | Test Method | GM13 Test Value | Testing Frequency | ||||||

Thickness (min. ave.) | 0.75mm | 1mm | 1.25mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm | (minimum) | |

nom. | nom. | nom. | nom. | nom. | nom. | nom. | Per roll | ||

lowest individual of 10 values | D5199 | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |

Formulated Density mg/l (min.) | D 1505/ D 792 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 90,000kg |

Tensile Properties (1) (min. ave.) | D 6693 Type IV | 9,000kg | |||||||

. yield strength | 11kn/m | 15kn/m | 18kn/m | 22kn/m | 29kn/m | 37kn/m | 44kn/m | ||

. break strength | 20kn/m | 27kn/m | 33kn/m | 40kn/m | 53kn/m | 67kn/m | 80kn/m | ||

. yield elongation | 12% | 12% | 12% | 12% | 12% | 12% | 12% | ||

. break elongation | 700% | 700% | 700% | 700% | 700% | 700% | 700% | ||

Tear Resistance (min. ave.) | D 1004 | 93N | 125N | 156N | 187N | 249N | 311N | 374N | 20,000 kg |

Puncture Resistance (min. ave.) | D 4833 | 240N | 320N | 400N | 480N | 640N | 800N | 960N | 20,000 kg |

Stress Crack Resistance (2) | D5397 | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | per GRI-GM10 |

(App.) | |||||||||

Carbon Black Content (range) | D 4218 (3) | 2.0-3.0% | 9,000kg | ||||||

Oxidative Induction Time (OIT) (min. ave.) (5) (a) Standard OIT | D 3895 D 5885 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 90,000kg |

— or —(b) High Pressure OIT | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | ||

Oven Aging at 85°C (5), (6) | D 5721 D 3895 D 5885 | per each formulation | |||||||

(a) Standard OIT (min. ave.) - % retained after 90 days — or — | 55% | 55% | 55% | 55% | 55% | 55% | 55% | ||

(b) High Pressure OIT (min. ave.) - % retained after 90 days | 80% | 80% | 80% | 80% | 80% | 80% | 80% | ||

(a) Standard OIT (min. ave.) | D 3895 D 5885 | 50% | 50% | 50% | 50% | 50% | 50% | 50% | per each formulation |

— or — | |||||||||

(b) High Pressure OIT (min. ave.) - % retained after 1600 hrs (9) | |||||||||

Key Features of LDPE Geomembranes

1). High Flexibility

- Soft and pliable, making it ideal for uneven surfaces or projects requiring contour adaptability.

- Maintains flexibility even at **low temperatures** (down to **-50°C**).

2). Chemical Resistance

- Resists mild acids, alkalis, and salts, though less robust than HDPE in harsh chemical environments.

3). Ease of Installation

- Lightweight and easy to weld (using heat or solvents), reducing labor and time costs.

4).Waterproofing Performance

- Provides excellent moisture and water barrier properties for low- to medium-stress applications.

5). Cost-Effective

- Generally cheaper than HDPE, making it suitable for budget-conscious, non-critical projects.

Application Scenarios

- Agricultural: Irrigation ponds, water retention systems.

- Landscaping: Decorative ponds, garden liners.

- Civil Engineering: Secondary containment liners, temporary erosion control.

- Roofing: Underlayment for waterproofing.

- Environmental: Light-duty waste covers or liners (non-hazardous).

Why choose Haoyang Geomembrane?

1. Imported Raw Materials

High-quality raw materials sourced from **Saudi Arabia** ensure superior product performance and consistency from the source.

2. World-Leading 10m Blown Film Production Line

Equipped with advanced five-layer co-extrusion technology, capable of producing both smooth and textured geomembranes with a maximum width of 10 meters.

3. Direct-from-Factory Production

As a manufacturer, we guarantee premium quality while offering the most competitive prices by eliminating middlemen.

4. Fast Delivery

High daily output of 70 tons ensures timely delivery to meet urgent project timelines.

5. One-Stop Solution

Beyond manufacturing and sales, we provide **professional project construction teams** to deliver end-to-end solutions for seamless project execution.