High Quality Composite Geomembrane Liner

1. Excellent anti-seepage performance: Made of high-density polyethylene and other high-quality materials, with a dense molecular structure, it can effectively prevent liquid penetration and is suitable for anti-seepage projects in water conservancy and environmental protection.

2. Outstanding mechanical strength: The composite process enhances tensile and tear strength, and has strong anti-puncture ability.

3. Excellent environmental resistance: Resistant to acid and alkali, corrosion-resistant, and resistant to ultraviolet aging.

4. Convenient and efficient construction: Lightweight, simple and reliable splicing method, can be quickly laid, shortening the construction period.

5. High comprehensive cost performance: Equipped with multiple functions such as anti-seepage and reinforcement, reduces the use of additional materials, and requires less maintenance in the future.

High Quality Composite Geomembrane Liner: The Ultimate Solution for Modern Engineering Projects

In the realm of civil engineering, environmental protection, and infrastructure development, finding reliable materials that balance durability, efficiency, and cost-effectiveness is crucial. Among these materials, the Composite Geomembrane stands out as a game-changer, and its specialized variant, the Composite Geomembrane Liner, has become indispensable for a wide range of projects. This article explores why high-quality Composite Geomembrane Liner is the top choice for engineers and project managers worldwide, delving into its key advantages, applications, and more.

1. Unmatched Impermeability: Why Composite Geomembrane Liner Leads in Seepage Control

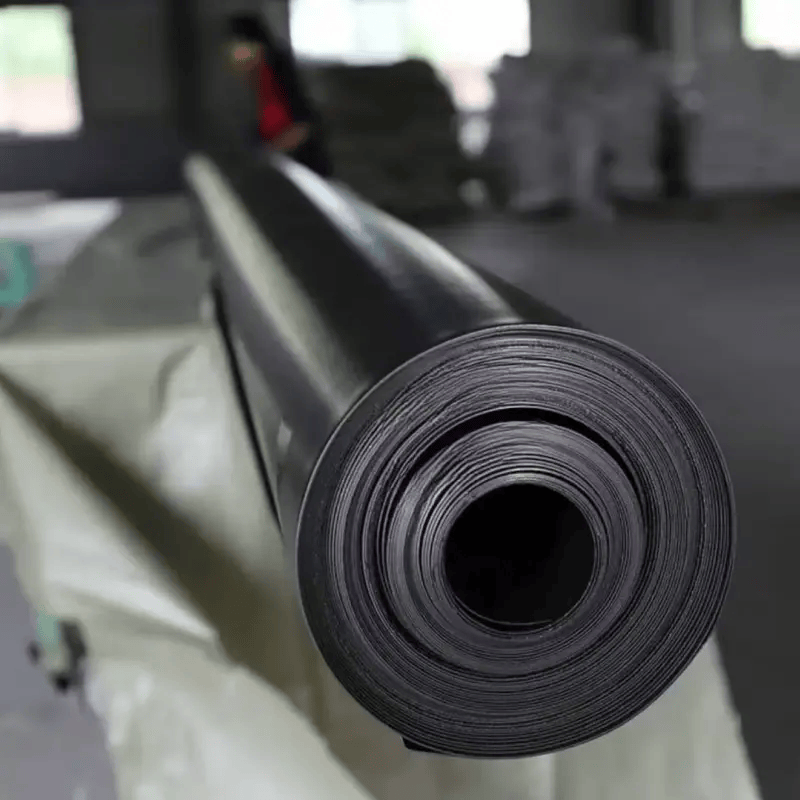

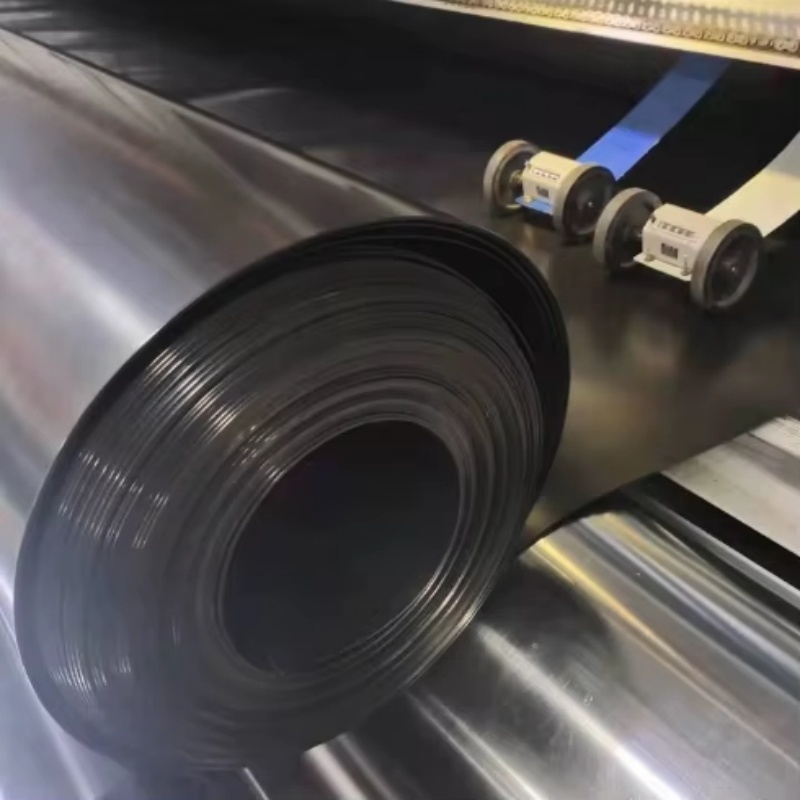

When it comes to preventing liquid or gas leakage, few materials can rival the performance of a high-quality Composite Geomembrane. A Composite Geomembrane Liner is engineered by combining high-density polyethylene (HDPE) or polypropylene (PP) films with non-woven geotextiles, creating a barrier that is both flexible and impenetrable.

The core of this material’s impermeability lies in its manufacturing process. The plastic film layer is extruded to have a uniform thickness, with minimal pores or defects, ensuring that even the smallest molecules cannot pass through. The non-woven layer reinforces this structure, preventing tears or punctures that could compromise the barrier. Whether used in landfills to contain toxic leachate, reservoirs to retain water, or industrial ponds to prevent chemical seepage, the Composite Geomembrane consistently outperforms traditional materials like clay liners or concrete.

What sets the Composite Geomembrane Liner apart is its ability to maintain this impermeability over time. Unlike clay, which can crack under dry conditions or erode with water flow, the Composite Geomembrane resists degradation, ensuring long-term seepage control. This reliability makes it a cornerstone of sustainable engineering practices.

2. Exceptional Durability: Composite Geomembrane Stands the Test of Time

Engineering projects demand materials that can withstand harsh environmental conditions, and the Composite Geomembrane delivers on this front. A high-quality Composite Geomembrane Liner is designed to resist UV radiation, chemical corrosion, temperature fluctuations, and biological degradation—factors that often shorten the lifespan of other liners.

The plastic film component of the Composite Geomembrane is treated with additives that enhance its UV resistance, preventing brittleness and cracking even after years of exposure to sunlight. This is particularly vital for outdoor projects like agricultural reservoirs or mining tailings ponds. Additionally, the material’s resistance to acids, alkalis, and organic solvents makes it ideal for industrial applications, where contact with harsh chemicals is common.

Moreover, the composite structure ensures superior tensile strength and puncture resistance. During installation, heavy machinery or sharp rocks can pose a threat, but the Composite Geomembrane’s reinforced layers absorb impacts and distribute stress, reducing the risk of damage. This durability translates to lower maintenance costs and longer project lifespans, making it a cost-effective choice in the long run.

3. Versatile Applications: Where Composite Geomembrane Liner Shines

One of the greatest strengths of the Composite Geomembrane is its versatility, and the Composite Geomembrane Liner adapts seamlessly to diverse project needs. Let’s explore some key sectors where it has become indispensable:

Water Conservation: In reservoirs, canals, and irrigation systems, the Composite Geomembrane prevents water loss through seepage, ensuring efficient water usage—critical in regions facing water scarcity.

Waste Management: Landfills and hazardous waste sites rely on Composite Geomembrane Liner to contain leachate, protecting soil and groundwater from contamination.

Mining: The material lines tailings ponds, preventing heavy metals and pollutants from seeping into surrounding ecosystems.

Civil Engineering: It is used in road construction to separate different soil layers, preventing mixing and stabilizing foundations, and in tunnel projects to control water ingress.

This adaptability stems from the Composite Geomembrane’s ability to be customized—available in various thicknesses, sizes, and material combinations to suit specific project requirements. Whether for a small agricultural pond or a large-scale infrastructure project, there is a Composite Geomembrane solution that fits.

4. Easy Installation: Saving Time and Labor with Composite Geomembrane

Time is a critical factor in any construction project, and the Composite Geomembrane offers significant advantages in terms of installation efficiency. Unlike traditional liners that require extensive site preparation (such as compacting clay layers), the Composite Geomembrane Liner is lightweight and easy to handle, reducing the need for heavy equipment and manual labor.

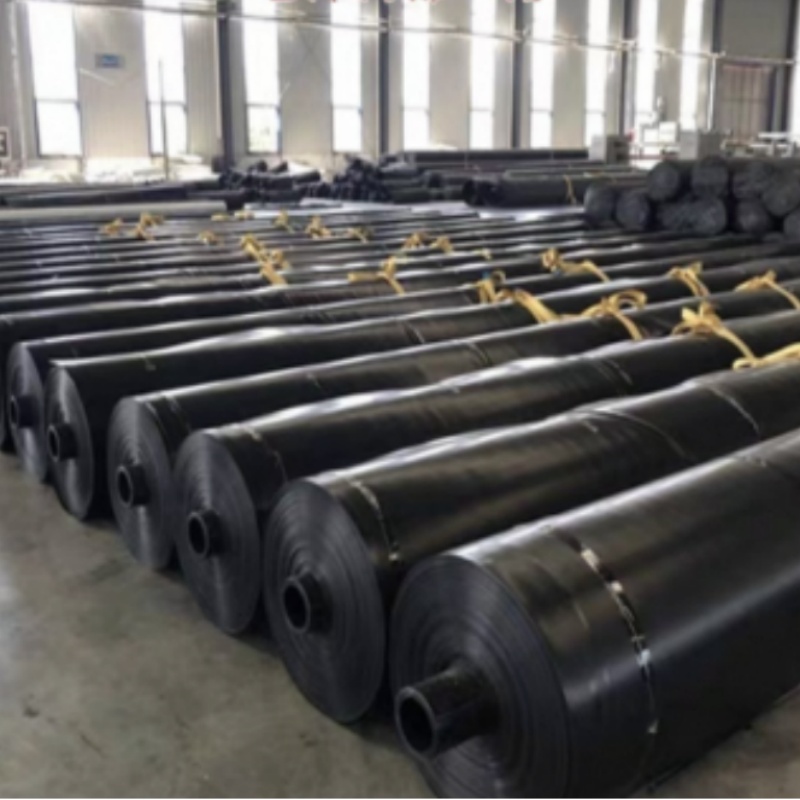

Installation begins with site preparation—clearing debris and ensuring a smooth, level surface. The Composite Geomembrane rolls are then unrolled and positioned, with seams joined using heat welding or adhesive techniques. These methods create strong, watertight bonds that match the integrity of the material itself. A skilled team can cover large areas quickly, minimizing project downtime.

The flexibility of the Composite Geomembrane also simplifies installation on uneven terrain. It conforms to slopes, curves, and irregular surfaces, ensuring full coverage without gaps. This adaptability reduces the risk of installation errors, which can lead to costly repairs later. For project managers, this means faster completion times, lower labor costs, and earlier project commissioning.

5. Cost-Effectiveness: Long-Term Savings with Composite Geomembrane Liner

While the initial cost of a high-quality Composite Geomembrane may be higher than some traditional materials, its long-term cost-effectiveness is undeniable. The Composite Geomembrane Liner reduces expenses across the project lifecycle, from installation to maintenance.

First, its quick installation cuts down on labor and equipment rental costs. Second, its durability minimizes the need for repairs or replacements. For example, a clay liner may require periodic re-compaction or resealing, adding to maintenance costs over time, whereas a Composite Geomembrane can last 20–30 years with minimal upkeep.

Additionally, the Composite Geomembrane’s efficiency in preventing leaks reduces the risk of environmental damage, which can result in hefty fines or remediation costs. In waste management or industrial projects, avoiding contamination incidents is not just a financial concern but a regulatory and ethical one.

When considering the total cost of ownership, the Composite Geomembrane emerges as a smart investment, offering reliable performance at a fraction of the long-term costs associated with less durable alternatives.

6. Environmental Benefits: Sustainable Engineering with Composite Geomembrane

Sustainability is a growing priority in engineering, and the Composite Geomembrane aligns with this goal. A high-quality Composite Geomembrane Liner is often made from recyclable materials, reducing its environmental footprint. Its long lifespan also means fewer replacements, lowering the demand for raw materials and reducing waste.

In applications like water conservation, the Composite Geomembrane plays a direct role in preserving natural resources by minimizing water loss. In waste management, it prevents soil and groundwater contamination, protecting ecosystems and public health. By supporting sustainable practices, the Composite Geomembrane helps projects meet environmental regulations and achieve green certifications.

7. Choosing the Right Composite Geomembrane Liner: Key Considerations

Not all Composite Geomembrane products are created equal, so selecting the right one is crucial. When choosing a Composite Geomembrane Liner, consider factors such as:

Material Quality: Opt for liners made from high-grade HDPE or PP, with proven resistance to environmental stressors.

Thickness: Thicker liners offer greater puncture resistance, making them suitable for high-risk applications like hazardous waste sites.

Manufacturer Reputation: Choose suppliers with a track record of producing reliable, tested Composite Geomembrane products.

Certifications: Look for liners that meet international standards, ensuring compliance with project specifications.

By prioritizing these factors, you can ensure that your Composite Geomembrane performs optimally throughout the project’s lifecycle.

8. Conclusion: Elevate Your Project with High-Quality Composite Geomembrane

The Composite Geomembrane has revolutionized modern engineering, and the Composite Geomembrane Liner stands as a testament to innovation in material science. Its unmatched impermeability, durability, versatility, ease of installation, cost-effectiveness, and environmental benefits make it the ideal choice for a wide range of projects.

Whether you’re working on a water reservoir, landfill, mining operation, or infrastructure development, investing in a high-quality Composite Geomembrane ensures reliability, efficiency, and long-term success. By choosing the right Composite Geomembrane Liner, you not only protect your project from risks but also contribute to sustainable engineering practices.

Make the smart choice—incorporate Composite Geomembrane into your next project and experience the difference it delivers.