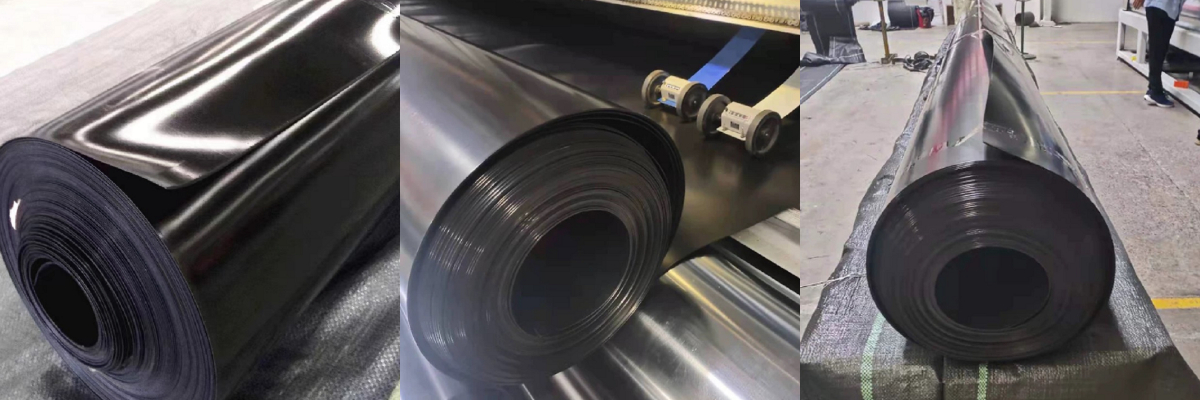

0.5mm LLDPE Geomembrane

Exceptional Flexibility: With 800% elongation, the liner molds to complex geometries, reducing installation time and material waste.

Cost-Effective Performance: Ideal for budget-sensitive projects where thicker liners are unnecessary.

Lightweight and Portable: Weighing approximately 0.45 kg/m², it simplifies logistics for remote or temporary installations.

0.5mm LLDPE Geomembrane: A Lightweight Solution for Versatile Containment

Linear Low-Density Polyethylene (LLDPE) geomembranes have revolutionized containment technology by offering a balance of flexibility, durability, and cost-efficiency. The 0.5mm LLDPE geomembrane, a thinner variant of its thicker counterparts, caters to applications requiring lightweight yet robust lining solutions. This article examines the technical attributes, applications, and benefits of 0.5mm LLDPE geomembranes, supported by performance data and real-world use cases.

1. Introduction to 0.5mm LLDPE Geomembranes

LLDPE is synthesized by copolymerizing ethylene with alpha-olefins, resulting in a material with exceptional tensile strength and resistance to environmental stress cracking. The 0.5mm thickness variant is engineered for projects where weight, flexibility, and ease of handling are critical, without compromising on performance. Its adaptability makes it ideal for secondary containment, temporary barriers, and lightweight cover systems.

2. Technical Specifications of 0.5mm LLDPE Geomembrane

The performance of 0.5mm LLDPE is defined by its physical, mechanical, and chemical properties, as outlined below:

Table 1: Physical and Mechanical Properties

| Parameter | Specification | Test Method |

Thickness (nominal) | 0.5 mm ± 5% | ASTM D5199 |

Density | 0.93–0.94 g/cm³ | ASTM D1505 |

Tensile Yield Strength | ≥ 15 MPa (MD/TD) | ASTM D638 |

Elongation at Break | ≥ 800% (MD/TD) | ASTM D638 |

Puncture Resistance | ≥ 200 N | ASTM D4833 |

Carbon Black Content | 2–3% (UV stabilization) | ASTM D1603 |

Environmental Stress Crack Resistance (ESCR) | ≥ 200 hours | ASTM D1693 (Condition B) |

Hydrostatic Resistance | > 50 m (water head) | ASTM D5385 |

Key Insights from the Table:

Thickness and Flexibility: The 0.5mm thickness enables superior conformability to irregular surfaces, while maintaining structural integrity.

Tensile Strength: Despite its thinness, the material withstands moderate stresses, making it suitable for non-critical applications.

UV Resistance: Carbon black additives ensure longevity in exposed environments, critical for outdoor installations.

Puncture Resistance: While lower than thicker liners, 200N resistance is adequate for protecting against minor abrasions.

3. Applications of 0.5mm LLDPE Geomembrane Liners

The lightweight nature of 0.5mm LLDPE expands its utility across industries:

3.1 Secondary Containment

Chemical Bunds: Liners for secondary spill containment under tanks or drums.

Fuel Farms: Barriers beneath aviation fuel storage in airports.

3.2 Temporary Barriers

Construction Sites: Dust suppression and sediment control during excavation.

Flood Management: Emergency dams and levees to redirect water flow.

3.3 Agricultural and Aquaculture

Greenhouse Floors: Moisture barriers to prevent soil contamination.

Fish Ponds: Temporary liners for seasonal aquaculture operations.

3.4 Waste Management

Landfill Covers: Protective layers over daily waste layers to control odors and pests.

Leachate Ponds: Supplemental liners in low-risk leachate collection systems.

3.5 Infrastructure

Roofing Membranes: Waterproofing for flat roofs and podium decks.

Tunnel Linings: Secondary barriers against groundwater infiltration.

4. Chemical and Environmental Resistance

LLDPE’s chemical inertness ensures compatibility with a broad range of substances:

Acids/Alkalis: Resistant to dilute acids (e.g., 10% sulfuric acid) and alkalis (e.g., 5% sodium hydroxide).

Hydrocarbons: Suitable for short-term contact with diesel, gasoline, and lubricants.

Salts: Impermeable to seawater and brine solutions.

Limitations: Avoid prolonged exposure to solvents (e.g., toluene), oxidizing agents (e.g., concentrated nitric acid), or animal/vegetable oils, which may cause swelling or degradation.

5. Installation and Maintenance Best Practices

Proper handling and installation are critical to maximize the lifespan of 0.5mm LLDPE liners:

5.1 Site Preparation

Subgrade Smoothing: Remove debris, rocks, and vegetation to prevent punctures.

Slope Ratios: Limit slopes to 2:1 (horizontal:vertical) to minimize liner displacement.

5.2 Welding and Seaming

Extrusion Welding: Ideal for thin materials; maintain a 75mm overlap.

Testing: Conduct daily peel and shear tests to verify seam integrity.

5.3 Temperature Management

Installation Window: Avoid temperatures below -10°C (risk of brittleness) or above 60°C (risk of deformation).

5.4 Protection Measures

Geotextile Overlays: Use nonwoven geotextiles to shield against UV exposure and abrasion.

Ballast: Secure edges with sandbags or concrete blocks to prevent wind uplift.

5.5 Inspections

Electro-Leak Location (ELL): Detect breaches using a 33V/m² electric field.

Patching: Repair defects with 100mm x 100mm patches of the same material.

6. Cost-Benefit Analysis

The 0.5mm LLDPE geomembrane offers a compelling value proposition:

Material Costs: Approximately 30–40% cheaper per square meter than 1mm HDPE alternatives.

Installation Savings: Reduced labor and equipment costs due to lightweight handling.

Lifecycle Costs: Suitable for temporary or low-risk applications, avoiding over-engineering expenses.

Example: A 1,000 m² secondary containment project using 0.5mm LLDPE could save 2,500–4,000 compared to thicker liners, with minimal compromise on performance.

7. Sustainability Considerations

0.5mm LLDPE geomembranes align with sustainable practices by:

Resource Efficiency: Thinner profiles reduce plastic consumption without sacrificing functionality.

Recyclability: Post-industrial scrap can be repurposed into drainage boards or composite materials.

Extended Usability: Durable enough for reuse in temporary applications, minimizing waste.

Conclusion

The 0.5mm LLDPE geomembrane represents a breakthrough in containment technology, offering a lightweight, flexible, and economical solution for non-critical applications. Its versatility across industries, coupled with robust chemical resistance and ease of installation, makes it an indispensable tool for modern engineering challenges. By prioritizing quality control during fabrication and adhering to best practices in the field, stakeholders can leverage this material to achieve sustainable, cost-effective outcomes. Whether protecting the environment, managing water resources, or ensuring industrial safety, the 0.5mm LLDPE geomembrane delivers reliability without compromise.