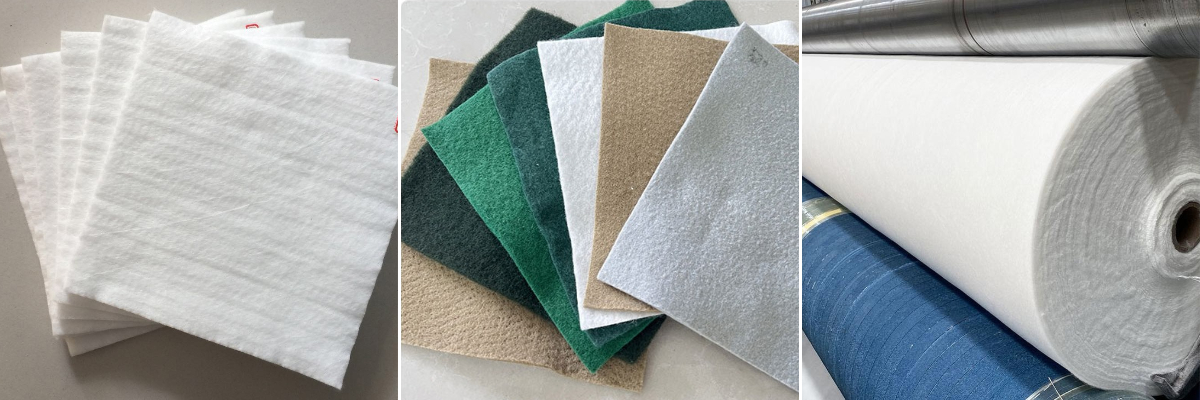

200g PET Filament Nonwoven Geotextile

1. Superior Filtration and Separation: Optimized pores enable efficient water flow while retaining soil, preventing erosion and stabilizing roadbeds, drains, and embankments.

2. High Tensile Strength and Durability: Premium PET filaments provide high tensile strength and deformation resistance, ensuring long - term performance under heavy loads and harsh conditions.

3. Enhanced Chemical and Biological Resistance: PET offers strong resistance to chemicals, acids, alkalis, and biological degradation, ideal for contaminated areas and waste treatment sites.

4. Lightweight and Cost - Effective: Lightweight design eases handling and installation. Its long lifespan, low maintenance, and competitive price deliver long - term cost savings.

The 200g PET Filament Nonwoven Geotextile is a high-performance geosynthetic material. Crafted from premium PET filaments, it combines excellent physical properties like high tensile strength and efficient filtration capabilities. Ideal for a wide range of civil engineering and environmental projects, it ensures long-lasting performance and reliability.

1. Product Performance

Property | Specification |

Weight | 200g/m² |

Thickness | 1.2 - 1.5mm |

Tensile Strength (MD/TD) | ≥15kN/m / ≥12kN/m |

Elongation at Break (MD/TD) | ≤35% / ≤40% |

CBR Puncture Strength | ≥1.8kN |

OTR (Oxygen Transmission Rate) | Low |

Water Permeability | High |

Grab Tensile Strength (MD/TD) | ≥2.5kN / ≥2.0kN |

Tear Strength (Elmendorf Method, MD/TD) | ≥0.4kN / ≥0.3kN |

Bursting Strength | ≥0.35MPa |

UV Resistance | Retains 85% of tensile strength after 500 hours of UV exposure |

2. Application Scenarios

(1) Road construction:

In highway and railway projects, the 200g PET Filament Nonwoven Geotextile acts as a separation layer between different soil layers. It prevents intermixing of fine and coarse - grained soils, ensuring the stability of the roadbed. Additionally, its high tensile strength helps reinforce weak soil areas, reducing the risk of settlement and extending the service life of the road. For example, in mountainous road construction, it can effectively prevent soil movement caused by slope instability.

(2) Drainage systems:

Installed in drainage ditches, retaining walls, and foundation drains, the geotextile allows water to pass through while filtering out soil particles. This prevents clogging of drainage pipes and channels, ensuring continuous and efficient water flow. In urban stormwater management systems, it helps in quickly draining excess rainwater, reducing the likelihood of flooding and soil erosion around infrastructure.

(3) Landscaping:

In gardens, parks, and golf courses, the geotextile is used to protect soil from erosion caused by rain and wind. It also serves as a barrier to prevent weed growth, reducing the need for herbicides. When creating raised garden beds, it can be placed at the bottom to separate the soil from the underlying ground, preventing the intrusion of unwanted roots and maintaining soil structure.

(4) Waste management:

In landfills, the geotextile is utilized for separation and filtration purposes. It separates waste materials from the surrounding soil, preventing contamination of groundwater. Its high chemical resistance allows it to withstand the corrosive environment within landfills. Moreover, in leachate collection systems, it helps filter out solids from the liquid waste, facilitating easier treatment and disposal.

(5) Coastal protection:

Along shorelines and beaches, the geotextile can be used to construct erosion - control structures. It is often combined with sand or gravel to create permeable breakwaters or revetments. The geotextile's filtration property allows water to pass through while retaining the fill material, reducing the impact of waves on the shoreline and protecting coastal infrastructure.

(6) Mine tailings management:

When handling mine tailings, the geotextile acts as a separation layer between the tailings and the underlying soil. It prevents the migration of heavy metals and other harmful substances into the soil and groundwater. Its high - strength and durability ensure long - term containment of the tailings, minimizing environmental risks associated with mining operations.

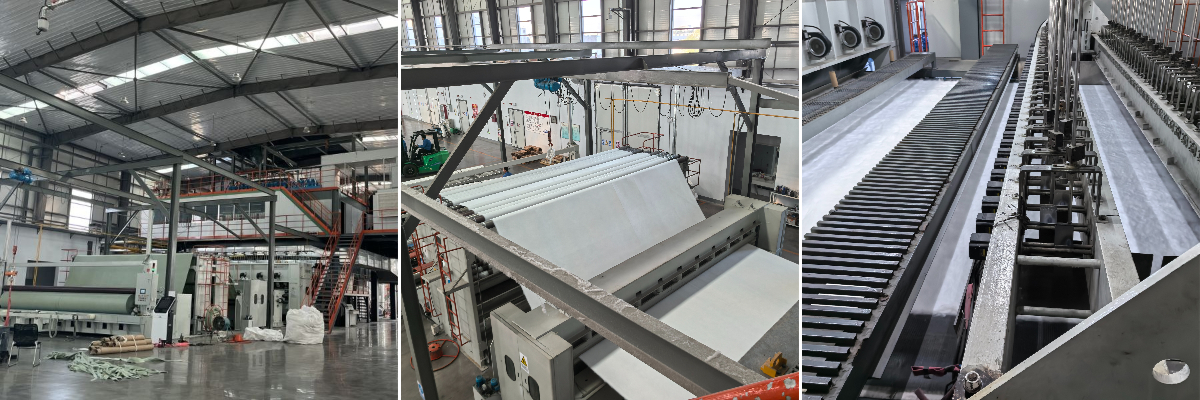

3. Advantages of Haoyang Environmental Co., Ltd.

Advanced Tech: State-of-the-art production lines ensure high - quality products.

Strict QC: Comprehensive quality checks at every production stage.

Customization: Tailor products to specific project requirements.

R & D: Strong team for continuous product innovation.

Global Reach: Wide - spread sales network and prompt after - sales service.

4. Factory Display

Haoyang's factory covers an area of over 250 mu, with more than 40,000 square meters of standardized industrial plants. It has 26 modern geosynthetic material production lines with a total production capacity of approximately 120 million tons per year. Haoyang has the first domestic production line of twin-screw intelligent swing filament geotextile The clean and organized production environment, along with advanced testing facilities, guarantees efficient production and reliable product quality.

5. Packaging and Shipping

Packaging: Rolled on sturdy cores, wrapped in waterproof PE film. Customizable packing.

Shipping: Domestic: Express (1 - 3 days) or standard (3 - 7 days). International: Sea freight (cost - effective, 15 - 45 days) or air freight (fast, 3 - 7 days). Provide tracking numbers for real - time monitoring.