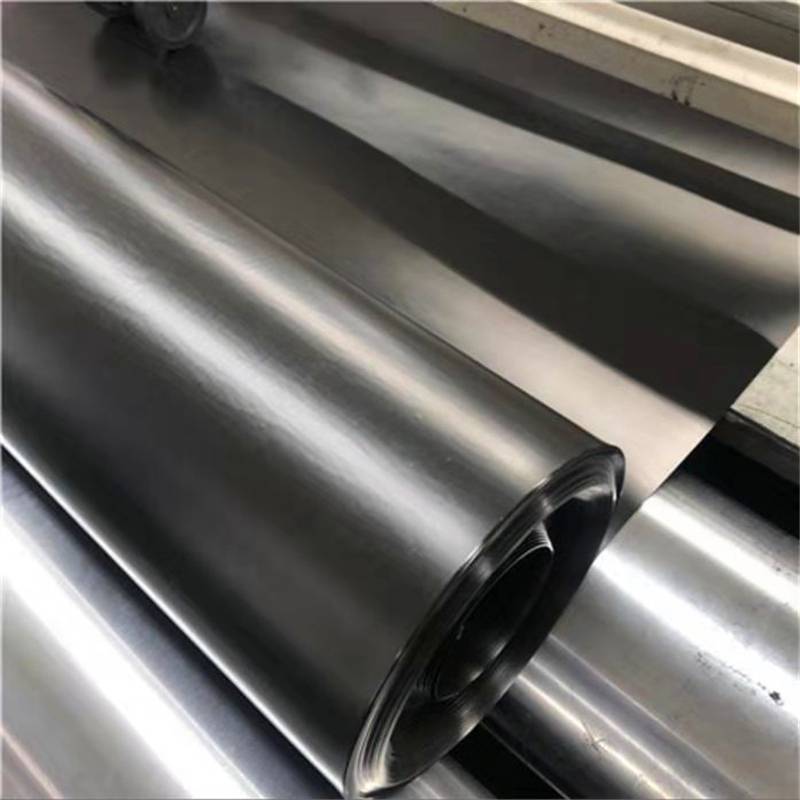

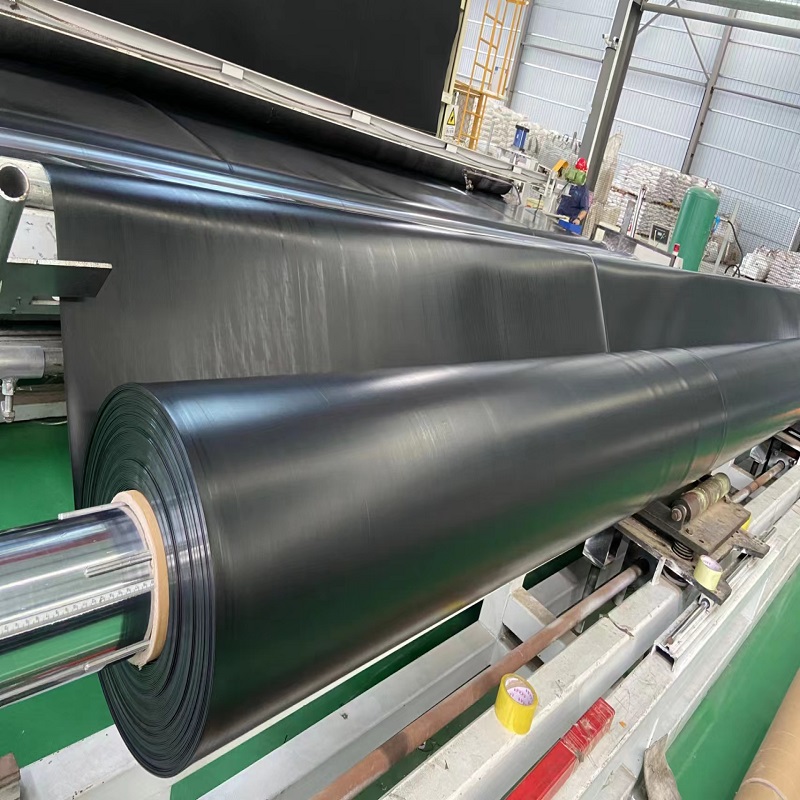

2mm HDPE Geomembrane

1. Environmental Protection: Prevents soil/water contamination by isolating hazardous materials.

2. Lightweight and Easy to Install: Simplifies transportation, handling, and deployment, even in remote areas.

3. Puncture and Tear Resistance: Withstands rough surfaces, roots, and animal activity in applications like mining or agriculture.

4. Versatility: Suitable for diverse industries, including waste management, aquaculture, hydropower, and infrastructure projects.

2mm HDPE Geomembranes are pivotal in modern infrastructure projects requiring impermeable barriers. The 2mm HDPE geomembrane, thicker than standard variants, offers enhanced durability and load-bearing capacity, making it ideal for demanding applications. This article examines its technical attributes, industrial uses, and comparative advantages, supported by empirical data and real-world performance metrics.

1. Technical Specifications

Manufactured via extrusion or calendaring, 2mm HDPE geomembranes exhibit superior mechanical properties while maintaining chemical inertness. Key parameters are outlined below:

Table 1: Physical and Mechanical Properties of 2mm HDPE Geomembrane

| Parameter | Value | Test Method |

Thickness (nominal) | 2.0 mm ± 5% | ASTM D5199 |

Density | 0.94–0.96 g/cm³ | ASTM D1505 |

Tensile Yield Strength | ≥35 MPa (MD/TD) | ASTM D6693 |

Elongation at Break | ≥650% (MD/TD) | ASTM D6693 |

Puncture Resistance | ≥600 N | ASTM D4833 |

Tear Resistance (Trapezoid) | ≥150 N | ISO 34-1 |

Carbon Black Content | 2–3% | ASTM D1603 |

UV Resistance (ASTM G154) | ≥85% strength retention after 6,000 hours | - |

Hydrostatic Resistance | >2,000 kPa | ASTM D5385 |

MD = Machine Direction; TD = Transverse Direction

Chemical Resistance

The inert polyethylene structure resists aggressive chemicals:

Acids: <3% weight change after 30-day exposure to 20% sulfuric acid.

Alkalis: <1% dimensional change in 15% sodium hydroxide.

Organics: <0.1% swelling in jet fuel (ASTM D471).

2. Industrial Applications

The 2mm thickness enhances suitability for high-stress environments:

2.1 Mining and Mineral Processing

Heap Leach Pads: Thicker liners withstand abrasion from ore particles. A Chilean copper mine reported 99.8% solution retention over five years using 2mm HDPE.

Tailings Dams: Critical for preventing seepage in arsenic-laden waste. Field tests show 0.0001 L/s/m² permeability, meeting Global Industry Standard on Tailings Management (GISTM).

2.2 Chemical Containment

Secondary Containment: Used beneath steel tanks storing hydrochloric acid (30%). Spill tests show zero leakage through seams after 72 hours.

Brownfield Remediation: Caps contaminated sites with PCBs exceeding 50 mg/kg. Post-installation soil sampling confirms 99.9% pollutant isolation.

2.3 Hydraulic Engineering

Canal Liners: Textured 2mm variants increase friction angles to 35°, preventing slippage in 2:1 slopes. A 10 km irrigation canal in Egypt reduced seepage by 85%.

Reservoirs: Withstands water pressures up to 15 m depth. A 200,000 m³ reservoir in Malaysia maintained impermeability despite 50-year rainfall patterns.

2.4 Aquaculture

Offshore Cages: 2mm HDPE withstands wave heights of 6 m and UV exposure in tropical waters. Norwegian salmon farms report 30% longer lifespan versus 1.5mm liners.

Shrimp Ponds: Smooth liners reduce biofouling by 60%, cutting harvest cleaning costs by $1,200/ha annually.

3. Performance Advantages

3.1 Mechanical Robustness

Puncture Resistance: 600 N rating (50% higher than 1.5mm) prevents damage from sharp rocks or equipment.

Tear Strength: 150 N trapezoid resistance minimizes propagation of accidental cuts.

3.2 Longevity

Field data from arid climates (Arizona, USA) project a 150-year lifespan for 2mm HDPE under protective cover. Accelerated weathering tests (5,000 hours UV exposure) show <10% embrittlement.

3.3 Cost Efficiency

Lower Lifecycle Costs: Despite 20% higher material cost vs. 1.5mm, total ownership costs reduce by 35% due to fewer repairs and replacements.

Installation Speed: Wider rolls (6m x 100m) reduce welding seams by 40%, cutting labor by 25%.

4. Installation Guidelines

Proper deployment ensures performance:

4.1 Subgrade Preparation

Compaction: Achieve ≥98% modified Proctor density for load-bearing surfaces.

Slope Stability: Maximum gradient of 2:1 for textured liners; 1.5:1 for smooth variants.

4.2 Seaming Techniques

Extrusion Welding: Preferred for seams >20cm, achieving 98% of base material strength.

Dual-Track Welding: Creates a 50mm wide seal with 2.5 kN/m peel strength.

4.3 Quality Assurance

Vacuum Box Testing: Detects 99% of seams with ≥0.5mm leaks.

Destructive Testing: Tensile tests on 1% of seams ensure compliance with ASTM D7176.

5. Case Study: 2mm HDPE in a Gold Mine Heap Leach Pad

Project: Expansion of a 500-acre gold mine heap leach facility in Nevada, USA.

Challenge: Acidic leach solution (pH 1.5) and abrasive ore particles.

Solution: Dual 2mm HDPE liners with a nonwoven geotextile interlayer.

Outcomes:

Solution seepage reduced to <0.001 L/s/m².

Seam integrity maintained after 10 years, despite 1.2 m annual rainfall.

Abrasion resistance tests showed <0.1mm wear over 5 years.

6. Emerging Trends

6.1 Nanotechnology Integration

Addition of carbon nanotubes (CNTs) enhances tensile strength by 40% and conductivity by 500%, enabling cathodic protection in aggressive environments.

6.2 3D-Printed Liners

Prototype 2mm HDPE liners with internal reinforcement grids improve puncture resistance by 70% while reducing material use by 15%.

6.3 Biodegradable HDPE

Research into bio-based additives aims to accelerate biodegradation in landfills, with pilot projects showing 30% mass loss in 5 years under industrial composting conditions.

7. Conclusion

The 2mm HDPE geomembrane represents a paradigm in heavy-duty containment solutions, balancing exceptional mechanical strength with chemical resilience. Its proven performance in mining, chemical, and hydraulic sectors underscores its role as a sustainable, low-maintenance infrastructure component. As industries face stricter environmental regulations and climate resilience demands, the 2mm HDPE geomembrane will remain a critical tool in safeguarding ecosystems and human health.