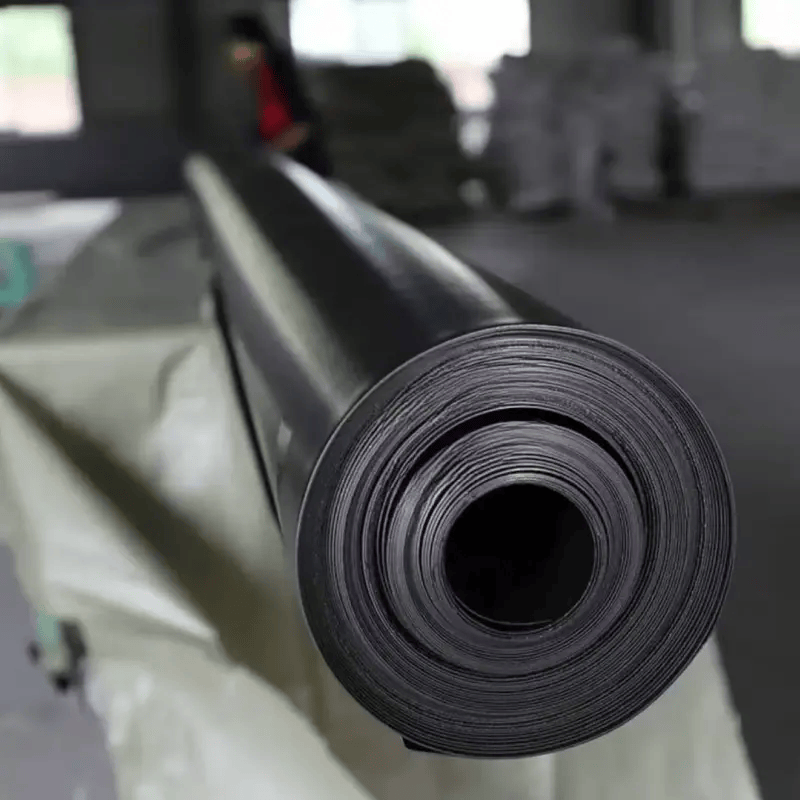

1.0mm High-Quality Anti-Seepage HDPE Geomembrane

1. Super strong water-proofing: Using high-density polyethylene (HDPE) raw material, the molecular structure is tight. With a thickness of 1.0mm, it can effectively prevent the penetration of water, sewage, and chemical liquids.

2. Excellent durability: It has the characteristics of resisting ultraviolet rays, aging, and acid-base corrosion. It remains stable in the temperature range of -60℃ to 80℃.

3. High mechanical properties: The tensile strength is ≥ 28MPa, and the elongation at break is ≥ 700%. It can withstand foundation settlement and external pulling forces, is not prone to damage during construction.

4. Convenient and economical: The material is lightweight, with a thickness of 1.0mm, which balances performance and cost. The welding construction efficiency is high.

Introduction

The anti-seepage engineering material is made of high-density polyethylene (HDPE) as the core raw material. Its main component is HDPE resin, with additives such as antioxidants and anti-ultraviolet agents added. It is formed through extrusion and calendering processes. With a thickness of 1.0mm, it is suitable for scenarios such as landfill sites and artificial lakes, and is a key material for efficient anti-seepage. It has strong anti-seepage performance (efficiency over 99.9%), is resistant to weathering and durable (-60℃ to 80℃ stable, with a lifespan of 30 years +), has excellent mechanical properties, is easy to construct and has controllable costs.

Technical Parameter

| Parameter Name | Specification / Value | Unit |

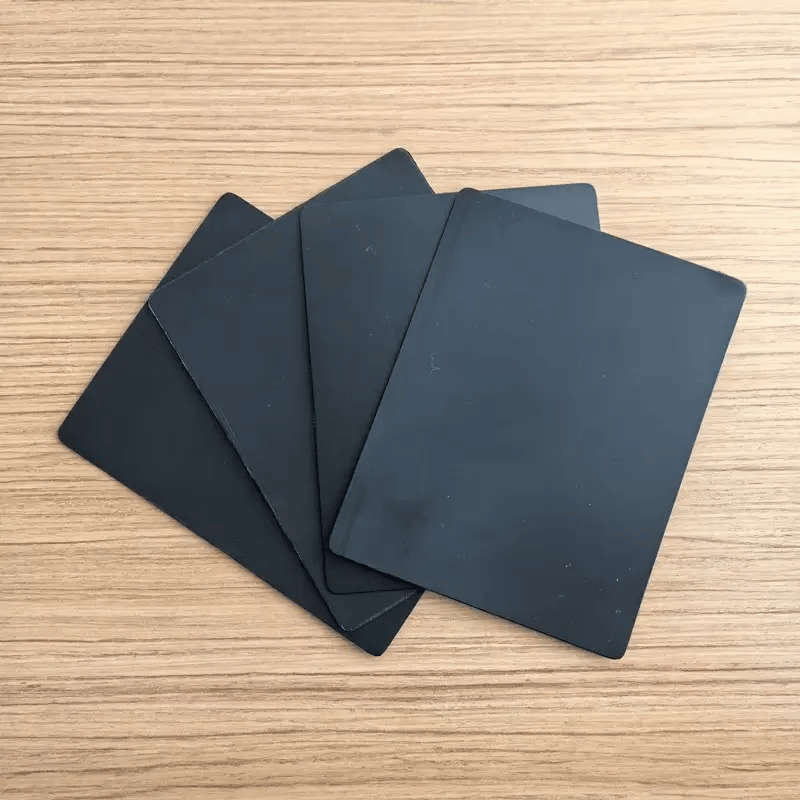

| Nominal Thickness | 1 | mm |

| Thickness Deviation | ±0.05 | mm |

| Tensile Strength (MD) | ≥28 | MPa |

| Elongation at Break (TD) | ≥650 | % |

| Tear Strength (MD) | ≥800 | N/m |

| Hydraulic Conductivity | ≤1.0×10⁻¹³ | cm/s |

| Service Temperature Range | -60 ~ 80 | ℃ |

| Melting Point | 130 ~ 135 | ℃ |

| Base Material | High-Density Polyethylene (HDPE) | - |

| Seam Strength (After Welding) | ≥80% of Base Material Strength | - |

| UV Resistance | Meet GB/T 17643-2011 Standard | - |

| Chemical Resistance | Resistant to acids, alkalis, and general organic solvents | - |

Factors influencing prices

| Influence Factor | Details | Impact on Price |

| Thickness | 1.0mm is a common thickness. Generally, the thicker the geomembrane, the higher the price as more material is used. | Usually higher than thinner options like 0.5mm. |

| Raw Materials | Virgin materials result in better quality but cost more; recycled materials are cheaper. HDPE is the main material. | Virgin material - made 1.0mm HDPE geomembranes are 20% - 30% more expensive than those of recycled materials. |

| Brand and Quality Standard | Well - known brands and products meeting high standards (e.g., national or international standards) are pricier. | High - standard compliant ones can be 30% costlier than non - standard ones. |

| Purchase Quantity | Larger orders often get discounts due to economies of scale. | Orders over 10,000 square meters may enjoy 10% - 20% price reduction. |

| Transportation | Longer distance and higher logistics costs increase the final price. | Adds about 0.2 - 0.5 yuan per square meter for long - |

Application scenario

1. Leachate barrier for landfill: Prevents leachate from penetrating, protects soil and groundwater, and avoids pollution spread.

2. Waterproofing for artificial lakes / landscape ponds: Prevents water leakage in the ponds, maintains stable water levels, and reduces water replenishment costs.

3. Leak prevention for sewage treatment ponds: Resists erosion from acidic and alkaline wastewater, prevents wastewater from seeping out, and ensures treatment effectiveness.

4. Leachate barrier for water conservancy projects: Used for channels, dams, etc., reduces water resource loss and enhances project stability.

5. Water retention for agricultural ponds: Reduces water loss through infiltration, meets irrigation needs, and improves water resource utilization.

6. Mining leak prevention project: Prevents leaching of slag wastewater, prevents soil heavy metal pollution, and protects the ecosystem.

Why choose Haoyang Environmental?

Exquisite quality stems from superior raw materials.

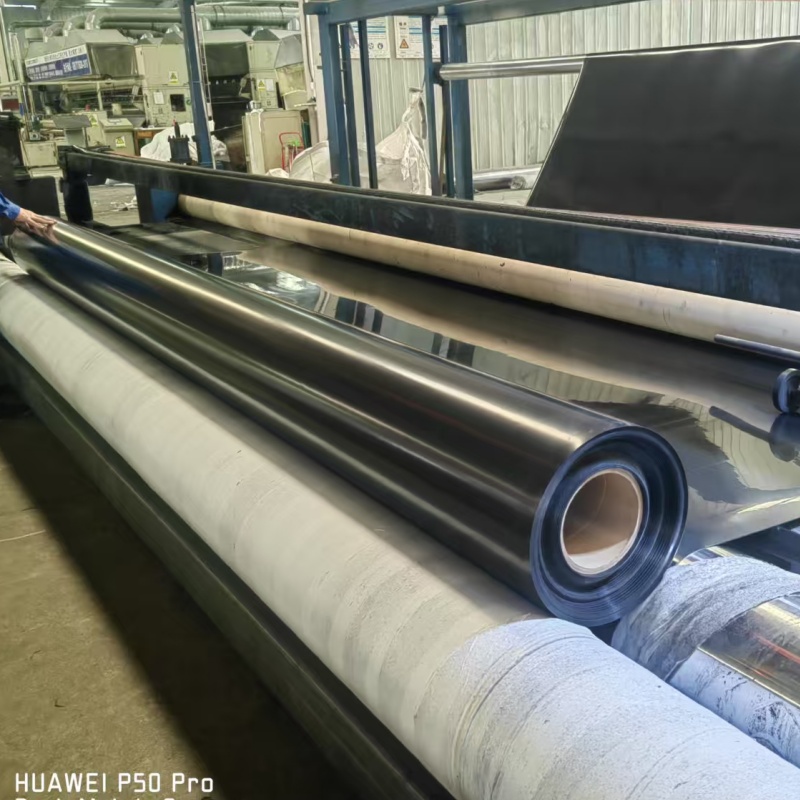

Haoyang Environment's 1.0mm HDPE geotextile membrane uses high-quality polyethylene virgin resin, combined with carbon black, anti-aging agents and other auxiliary materials. This ensures the quality from the very beginning. The advanced three-layer co-extrusion technology makes the molecular structure of the geotextile membrane more compact, featuring outstanding anti-seepage performance. The water vapor permeability coefficient K is <= 1.0*10-13 cm/(cm2·s·Pa), far exceeding that of ordinary waterproof materials.

Super durable, adaptable to various environments

It possesses excellent resistance to aging, UV rays and decomposition. Through special processing, it can maintain stability within an extreme temperature range of -60℃ to 80℃, unaffected by wind and sun exposure, and the material has a service life of up to 50 - 70 years. Moreover, it is resistant to corrosion by more than 80 kinds of strong acid and alkali chemical media, such as acids and alkalis. It can easily cope with complex environments in landfill sites or harsh conditions in chemical projects.

Excellent mechanical properties, ensuring project safety

This type of geotextile membrane from Haoyang has excellent mechanical strength. Its tensile strength at break reaches 28 MPa, and the elongation at break is 700%. Its high elasticity and strong deformation capacity enable it to effectively overcome uneven settlement of the base surface. In embankments, slopes, and other engineering projects, even if the foundation changes, it is not prone to damage and provides a solid guarantee for the safety of the engineering structure.

Efficient construction, saving overall costs

Rich product specifications, with widths ranging from 6m to 10m and thicknesses of 1.0mm, suitable for different project scales. Using hot-melt welding technology, the weld strength is high, the construction is convenient and fast, significantly shortening the construction period. At the same time, the production process is scientific, and the cost is lower than that of traditional waterproof materials. After calculation, using Haoyang 1.0mm HDPE geotextile membrane in the project can save costs by about 50%, with extremely high cost-effectiveness.