Geomembrane Sheet For Waterproofing

1.Excellent Waterproof Performance — Provides an impervious barrier to prevent leakage and seepage

2.High Chemical & UV Resistance — Performs reliably in harsh environmental conditions

3.Durable & Long Service Life — Strong tensile strength and puncture resistance

4.Wide Temperature Adaptability — Suitable for both hot and cold climates

5.Easy Installation & Welding — Flexible material supports efficient field construction

6.Environmental Protection Material — Non-toxic and compliant with international standards

Geomembrane sheets are one of the most widely used waterproofing and anti-seepage materials in civil, environmental, and geotechnical engineering. Manufactured from high-quality polymer materials such as HDPE and LDPE, geomembrane sheets provide a highly effective impermeable barrier that prevents water, chemicals, and contaminants from penetrating soil, structures, or storage systems.

Whether used in landfills, reservoirs, mining, construction, agriculture, or industrial storage facilities, geomembrane waterproofing systems play a critical role in environmental protection, structural stability, and long-term project safety.

Why Choose Geomembrane Sheet for Waterproofing?

Geomembrane sheets deliver multiple performance advantages, including:

Excellent Waterproofing Barrier — Creates a continuous anti-seepage layer to eliminate leakage risk

High Chemical & UV Resistance — Suitable for acidic, alkaline, saline, and high-sun exposure environments

Superior Tensile & Puncture Strength — Withstands mechanical stress, uneven settlement, and site loads

Durable & Long-Lasting — Engineered for decades of service life under normal conditions

Flexible & Easy to Install — Supports on-site welding and adapts to uneven terrain

Eco-Friendly & Safe — Non-toxic, compliant with environmental standards, and recyclable

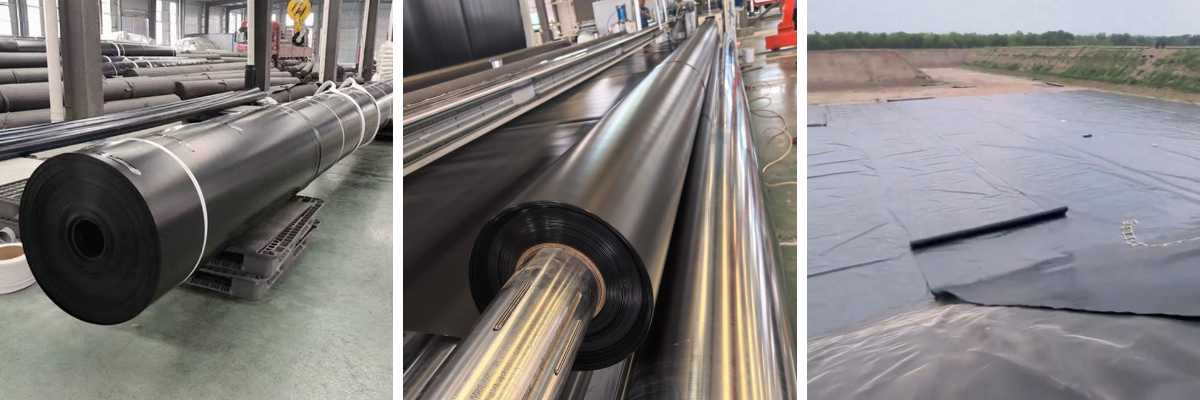

Common Applications

Geomembrane waterproofing sheets are widely applied in:

Landfill lining & capping systems

Mining heap-leach pads & tailing ponds

Reservoirs, canals & irrigation systems

Ponds, fish farms & aquaculture projects

Oil & chemical storage containment

Tunnels, basements & foundation waterproofing

Wastewater treatment plants

Wherever leakage control is critical, geomembranes provide a dependable solution.

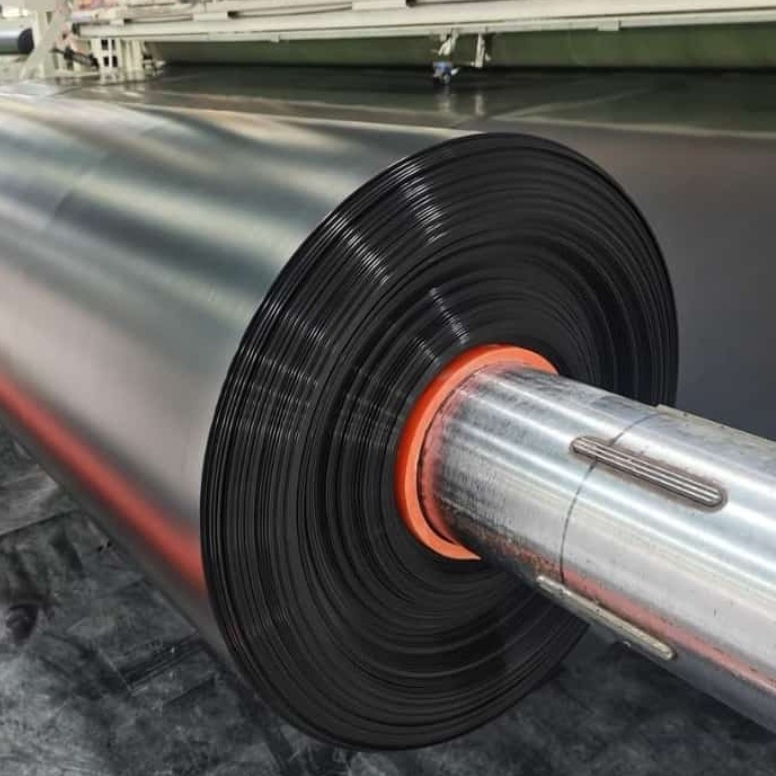

Production & Quality Assurance

High-quality geomembrane sheets are produced using 100% virgin resin combined with advanced extrusion or co-extrusion technology. Strict quality control ensures:

Uniform thickness

Smooth or textured surfaces as required

Strong weld performance

Compliance with international testing standards

Each batch typically undergoes mechanical, environmental, and durability testing to guarantee stable and consistent performance across all project conditions.

Customer Feedback

Here’s what our customers say about our geomembrane waterproofing systems:

“We have used your HDPE geomembrane in our landfill project, and the quality exceeded our expectations. Welding performance was excellent and installation efficiency was high.”

“The geomembrane sheets showed great durability and chemical resistance in our mining operation. We are very satisfied with the performance and technical support provided.”

“Professional service, fast delivery, and reliable waterproofing quality. We will definitely continue long-term cooperation.”

Positive project outcomes and repeat business reflect the trust and satisfaction of global clients.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Frequently Asked Questions (FAQ)

1. What is a geomembrane sheet used for?

A geomembrane sheet is used as a waterproof and anti-seepage barrier in engineering projects such as landfills, ponds, reservoirs, industrial containment, and construction foundations.

2. What thickness should I choose?

Common thickness options range from 0.5mm to 2.0mm.

Thin sheets (0.5–1.0mm) — ponds, landscaping, light containment

Medium sheets (1.0–1.5mm) — reservoirs, canals, aquaculture

Thick sheets (1.5–2.0mm and above) — landfills, mining, heavy-duty projects

The right thickness depends on project design and site conditions.

3. Are geomembrane sheets environmentally friendly?

Yes. High-quality geomembranes are non-toxic and help prevent soil and groundwater contamination by stopping leaks and chemical seepage.

4. How are geomembranes installed?

Sheets are laid on a prepared surface and welded using hot-wedge or extrusion welding equipment. Professional installers ensure seam strength and continuity.

5. How long is the service life?

With proper installation and design, HDPE geomembranes can provide 20–50 years of effective service life depending on conditions.

6. Can geomembranes be customized?

Yes — width, thickness, color (commonly black), and surface texture (smooth or textured) can be customized based on project needs.

Your Trusted Waterproofing Partner

Choosing the right geomembrane sheet ensures long-term waterproofing performance and environmental safety. With reliable materials, professional production standards, and technical support, you can protect your project from leakage risks and costly failures.