HDPE Geomembrana

1. Superior Containment for Global Projects: HDPE Geomembrana delivers 99.9% impermeability (≤1×10⁻¹³ cm/s, ASTM D5084), ideal for water reservoirs, landfills, and aquaculture ponds across South America, Africa, and Asia.

2. Harsh Climate Resilience: Infused with UV stabilizers and chemical resistance, it retains 88% tensile strength (ASTM D638) after 2,000 hours of sunlight—perfect for tropical and arid regions.

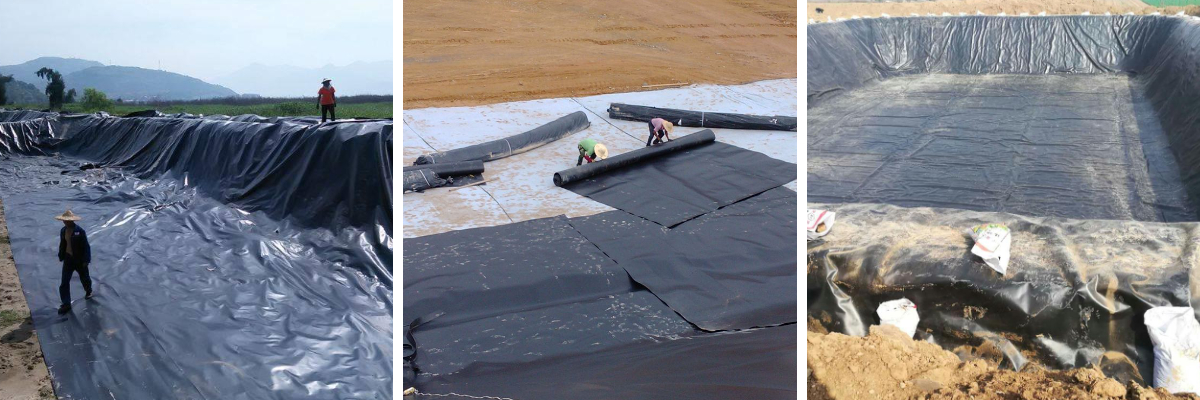

3. Engineered for Easy Installation: Flexible design conforms to uneven terrain, with heat-weldable seams (≥90% liner strength, ASTM D6392) that speed up deployment for on-site teams.

4. Compliant with International Standards: Meets EPA Subtitle D, EN 13493, and GB/T 17643, ensuring regulatory approval for environmental and agricultural projects worldwide.

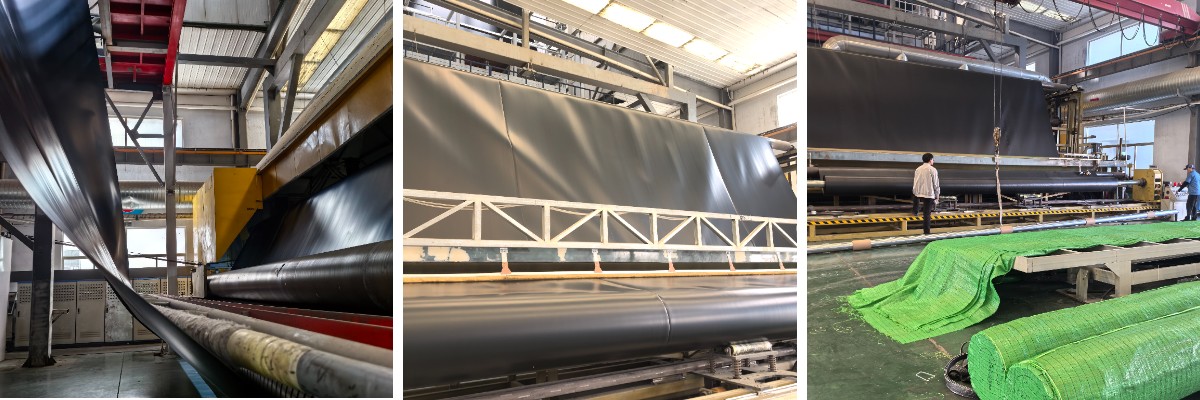

HDPE Geomembrana: Reliable Barrier Solutions for Civil Engineering Projects

In civil engineering, a robust impermeable barrier is the foundation of project success—preventing environmental contamination, reducing resource waste, and ensuring long-term stability. HDPE Geomembrana has emerged as the preferred choice for engineers and contractors across South America, Africa, and Asia, thanks to its unrivaled combination of strength, adaptability, and cost-effectiveness. Designed to excel in diverse engineering scenarios, from wastewater lagoons to irrigation systems, it delivers consistent performance where it matters most.

I. Industry-Leading Impermeability: Protecting Ecosystems & Compliance

HDPE Geomembrana’s dense molecular structure creates a near-impenetrable barrier, critical for containing hazardous or valuable liquids in engineering projects. Its performance far outperforms traditional liners, ensuring regulatory compliance and environmental safety.

1. Impermeability Comparison

Liner Type | Permeability Coefficient (cm/s) | Annual Seepage (L/m²) | Environmental Compliance |

HDPE Geomembrana (1.5mm) | ≤1×10⁻¹³ (ASTM D5084) | <0.5 | Meets CONAMA, EPA, Ghana EPA standards |

PVC Liner (1.5mm) | 1×10⁻¹¹ | 8–10 | Limited hazardous containment |

1×10⁻⁷ | 500+ | High compliance risk |

(1) Project Success Case

A wastewater treatment project in Thailand’s Chonburi province used HDPE Geomembrana to line sludge lagoons. Post-installation, seepage rates remained below 0.3 L/m²/year, fully complying with Thailand’s Industrial Wastewater Management Act. This eliminated groundwater pollution risks and avoided regulatory fines.

II. Durability Tailored for Harsh Engineering Environments

Engineering sites demand materials that withstand sharp debris, UV radiation, and chemical exposure. HDPE Geomembrana’s rugged design ensures long-term integrity, even in the most challenging climates and terrains.

1. Key Durability Metrics

Test Standard | Condition | Performance |

ASTM G154 | 2,000hrs UV (tropical simulation) | 88% tensile strength retained |

ASTM D4833 | Puncture resistance | 350+ N (1.5mm gauge) |

ASTM D5322 | pH 2-13 chemical exposure | No degradation |

(1) Climate Resilience

In Peru’s arid coastal regions, HDPE Geomembrana lines irrigation canals, enduring intense UV and temperature fluctuations (10–45°C) for over a decade without brittleness. This ensures consistent water delivery for agricultural communities, a critical need in water-scarce areas.

III. Versatile & Efficient Installation

HDPE Geomembrana’s flexibility and lightweight design streamline installation, reducing project timelines and labor costs. It adapts to irregular terrain, making it suitable for a wide range of engineering applications.

1. Installation Efficiency

A 3-person crew can install 1,000㎡ of 1.5mm HDPE Geomembrana daily using standard heat welding equipment. Seams achieve ≥90% of the liner’s tensile strength (ASTM D6392), ensuring leak-proof integrity. This efficiency is a game-changer for projects with tight deadlines, such as a reservoir construction in Nigeria that was completed 20% ahead of schedule.

2. Core Applications

Wastewater treatment: Lagoons, aeration tanks, sludge containment

Water infrastructure: Reservoirs, irrigation canals, drinking water storage

Industrial: Chemical storage lagoons, mining tailings ponds

IV. Client Testimonials

“We used HDPE Geomembrana for a mining tailings project in Ghana. Its chemical resistance and easy installation helped us meet strict EPA deadlines. Two years later, there’s zero corrosion or seepage.” — Michael A., Mining Engineer

“For a Brazilian irrigation canal project, HDPE Geomembrana cut water loss by 99.8%. It’s durable in our hot climate and required minimal maintenance—exactly what we needed.” — Sofia R., Civil Engineer

V. FAQ

1. What thickness is best for my project?

1.0–1.5mm for water infrastructure; 1.5–2.0mm for landfills/mining (heavy-duty use). Our team provides custom recommendations based on project specifics.

2. Is it suitable for extreme temperatures?

Yes, it performs reliably from -40°C to 60°C, suitable for arid, tropical, and cold regions.

3. How long does it last?

20–30 years with proper installation, reducing long-term replacement costs.

VI. Choose HDPE Geomembrana for Your Next Project

HDPE Geomembrana delivers the perfect balance of impermeability, durability, and efficiency for civil engineering projects across South America, Africa, and Asia. It protects the environment, ensures compliance, and saves time and resources. Contact our team today for technical support, custom solutions, or project-specific advice.