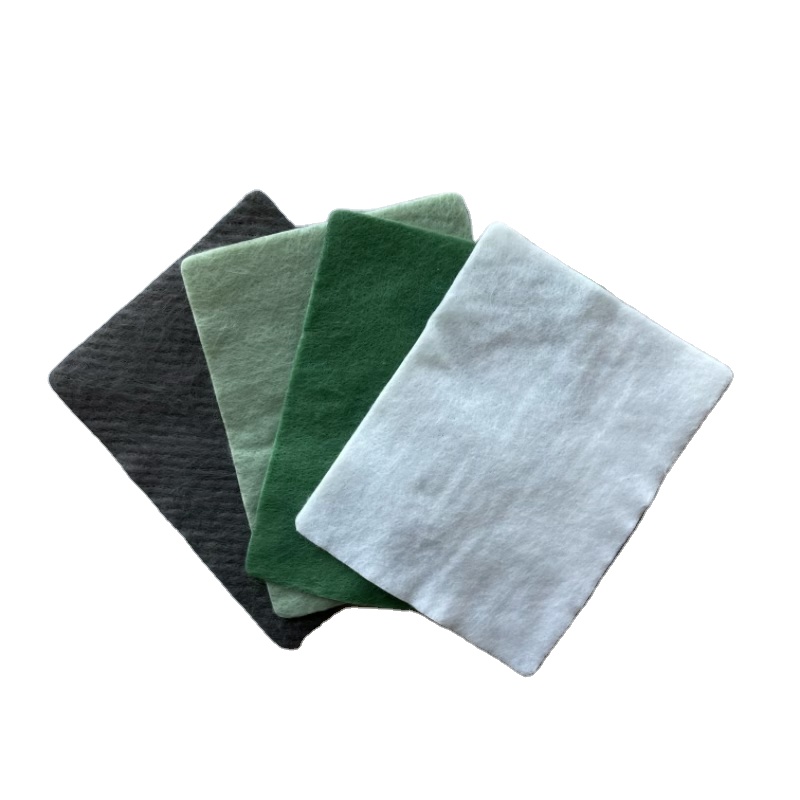

600g PP Nonwoven Geotextile

Cost-Effective Performance: Delivers optimal strength and durability at a competitive price point for moderate-load applications.

Chemical and Biological Resistance: Withstands harsh environments, including acidic soils and hydrocarbon exposure.

Lightweight and Flexible: Simplifies installation, reduces labor costs, and ensures conformal fitting on uneven terrain.

600g PP Nonwoven Geotextile: Technical Performance and Multidisciplinary Applications

Introduction

Polypropylene (PP) nonwoven geotextiles have revolutionized geotechnical engineering by offering a cost-effective, versatile solution for separation, filtration, reinforcement, and drainage. The 600g/m² PP nonwoven geotextile strikes a balance between mechanical performance and economic efficiency, making it a preferred choice for a wide range of civil engineering and environmental projects. This article examines the material’s properties, technical specifications, real-world applications, and competitive advantages, supported by empirical data and industry standards.

Material Composition and Manufacturing Process

PP nonwoven geotextiles are produced through a needle-punched or thermally bonded process, which interlocks continuous filaments or staple fibers into a stable, porous fabric. The 600g/m² variant is engineered for applications requiring moderate tensile strength and hydraulic efficiency. Key attributes include:

Fiber Type: 100% PP continuous filaments or staple fibers.

Manufacturing Method: Needle-punched to enhance fiber entanglement and dimensional stability.

Thickness: Typically 2.2–3.0 mm (manufacturing tolerance: ±0.2 mm).

Technical Specifications

The performance of 600g PP nonwoven geotextiles adheres to international standards (e.g., ASTM D4595, EN ISO 10319). Below is a compilation of critical parameters:

| Parameter | Value | Test Method |

Mass per Unit Area | 600 ± 5% g/m² | ASTM D5261 |

Thickness at 2kPa | 2.5–2.8 mm | ASTM D1777 |

Tensile Strength (MD/CD) | ≥18 kN/m (MD) | ASTM D4595 |

≥15 kN/m (CD) | ||

Elongation at Break | 40–70% | ASTM D4595 |

CBR Puncture Resistance | ≥2.8 kN | ASTM D6241 |

Apparent Opening Size (AOS) | 0.20–0.40 mm | ASTM D4751 |

Water Permeability | 0.2–1.5 cm/s | ASTM D4491 |

UV Resistance | ≥50% strength retention after 500 hrs | ASTM G154 |

Chemical Resistance | Resistant to acids, alkalis, and hydrocarbons | Laboratory exposure tests |

Melting Point | 160–170°C | DSC analysis |

Key Applications

The 600g/m² PP geotextile’s adaptability makes it suitable for diverse scenarios:

1. Temporary Roads and Work Pads

Function: Separation and reinforcement.

Details: Installed beneath aggregate layers to prevent subgrade contamination, supporting heavy construction traffic. A study by the U.S. Army Corps of Engineers demonstrates a 40% reduction in aggregate thickness when using geotextiles in temporary access roads.

2. Landfill Leachate Collection Systems

Function: Filtration and drainage.

Details: Placed above gravel drainage layers to prevent clogging by fine particles, ensuring efficient leachate flow. The 0.20–0.40 mm AOS retains >90% of soil particles larger than 0.18 mm.

3. Coastal and Riverbank Protection

Function: Erosion control and armor layer support.

Details: Combined with rock riprap to stabilize slopes, withstanding wave velocities up to 3 m/s. The material’s UV resistance ensures 5–7 years of service life in direct sunlight.

4. Agricultural Drainage

Function: Subsurface water management.

Details: Installed in trench drains to prevent soil infiltration while maintaining hydraulic conductivity. Cost savings of up to 25% compared to traditional gravel-only systems.

5. Sports Field Construction

Function: Separation and root zone stabilization.

Details: Placed beneath sand or gravel layers to prevent mixing with native soils, ensuring consistent turf conditions.

Performance Comparison with Alternatives

The table below contrasts the 600g PP geotextile with lighter (400g/m²) and heavier (800g/m²) PP variants, as well as PET alternatives:

| Parameter | 400g PP | 600g PP | 800g PP | 600g PET |

Tensile Strength (MD) | 12 kN/m | 18 kN/m | 22 kN/m | 25 kN/m |

CBR Puncture Resistance | 1.8 kN | 2.8 kN | 3.5 kN | 3.5 kN |

UV Resistance (500 hrs) | 40% | 50% | 45% | 70% |

Cost per m² | $0.35 | $0.50 | $0.75 | $0.65 |

Melting Point | 160°C | 160°C | 165°C | 250°C |

Note: PP geotextiles exhibit lower UV resistance and melting points compared to PET but offer superior chemical resistance.

Advantages of 600g PP Nonwoven Geotextile

1. Cost Efficiency for Moderate-Load Applications

The 600g/m² PP geotextile provides 50% higher tensile strength than 400g alternatives at a 43% lower cost per kN of strength compared to 800g variants. This makes it ideal for budget-constrained projects like temporary roads or agricultural drainage.

2. Resistance to Aggressive Environments

PP’s inherent chemical inertness allows it to withstand exposure to acids, alkalis, and hydrocarbons, making it suitable for landfill liners, chemical storage pads, and coastal installations.

3. Ease of Installation and Handling

The material’s lightweight design (600g/m² vs. 800g/m²’s 800g/m²) reduces labor costs by up to 20% during deployment. Its flexibility conforms to irregular substrates, minimizing wrinkles and ensuring uniform performance.

Conclusion

The 600g PP nonwoven geotextile exemplifies the synergy between practical engineering and economic viability. Its adaptability across sectors—from environmental protection to infrastructure development—highlights its value as a reliable, cost-effective solution. As industries prioritize sustainable, low-maintenance materials, PP geotextiles continue to play a pivotal role in modern construction practices.