220g 6.0mm 220g Composite Drainage Net

1. Tri-Layer Strength: 220g/6.0mm/220g composite net combines nonwoven filtration with PP core drainage, handling ≥50 kPa load for robust soil stabilization.

2. High-Flow Efficiency: 6.0mm core enables 30+ m³/h/m water drainage, ideal for stormwater management in roads, tunnels, and landfills.

3. Chemical & UV Resistance: Withstands acids, alkalis, and 1500+ hours of sunlight, ensuring longevity in harsh industrial/environmental projects.

4. Multi-Environment Versatility: Performs in -30°C to 80°C climates, adapting to polar foundations, tropical drainage, and everything in between.

220g/6.0mm/220g Composite Drainage Net: The Ultimate Drainage Solution

The 220g/6.0mm/220g Composite Drainage Net is a revolutionary geosynthetic product engineered to redefine the standards of water management and soil stabilization. Combining a robust core with high-quality nonwoven layers, this composite net offers unparalleled performance across a wide range of applications, from large-scale infrastructure projects to delicate environmental restoration initiatives.

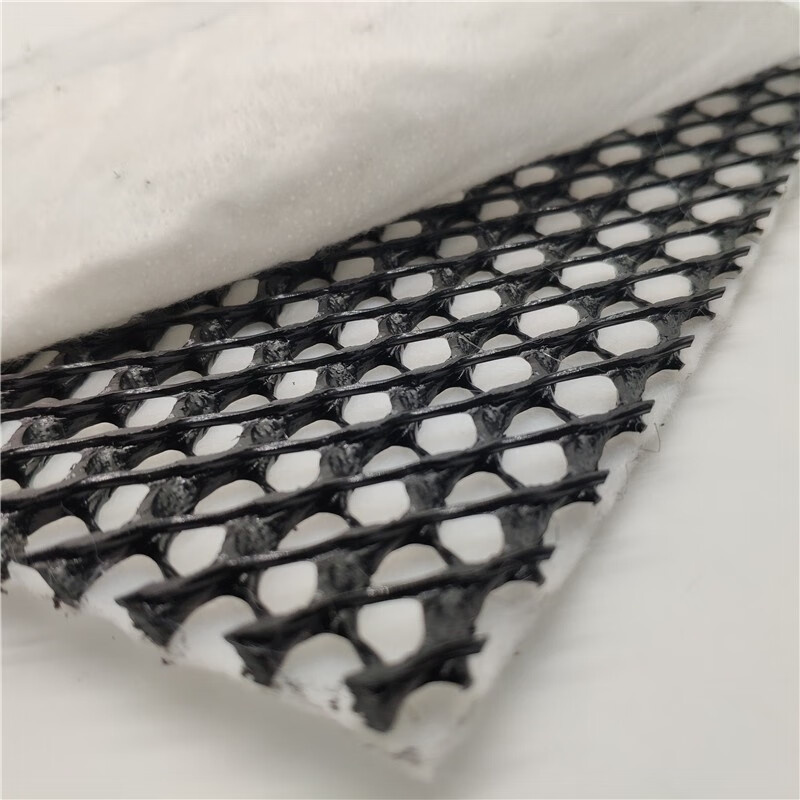

1. Unique Three - layer Structure

The composite drainage net features a distinctive three - layer design that maximizes its functionality:

Outer Layers: Composed of 220g nonwoven geotextiles, these layers act as a first line of defense. They provide excellent filtration, preventing soil particles and debris from entering the drainage core while allowing water to permeate freely. The nonwoven material also offers good tensile strength and flexibility, enabling it to conform to irregular surfaces.

Core Layer: The 6.0mm thick central core is the heart of the drainage net. Made from high-strength polypropylene (PP) material, it has a structured, honeycomb-like design. This unique structure creates a high - flow channel for water, ensuring rapid and efficient drainage under various conditions. The core's rigidity allows it to withstand high loads without collapsing, maintaining its drainage capacity even when subjected to heavy pressure.

2. Technical Specifications

Property | Specification | Testing Standard |

Total Weight | 1310g/m² (870g net core+440g geotextile) | ASTM D5261 |

Core Thickness | 6.0mm | ASTM D5199 |

Tensile Strength (Machine Direction) | ≥20 kN/m (nonwoven layers) | ISO 10319 |

Tensile Strength (Cross Direction) | ≥18 kN/m (nonwoven layers) | ISO 10319 |

Hydraulic Conductivity | Up to 35 m³/(h·m) | ASTM D4491 |

Compressive Strength | Up to 80 kPa | ASTM D1883 |

Chemical Resistance | Excellent against common acids, alkalis, and industrial chemicals | ASTM D543 |

UV Resistance | Retains ≥85% of tensile strength after 1500 hours of UV exposure | ASTM G154 |

3. Diverse Application Scenarios

(1) Infrastructure Construction

Road and Railway Projects: Installed beneath roadbeds and railway tracks, the composite drainage net prevents water accumulation, reduces soil erosion, and enhances the stability of the subgrade. It can withstand the heavy loads of traffic and trains, ensuring the long - term durability of the infrastructure.

Building Foundations: Used around building foundations, it effectively drains groundwater, preventing soil heave and moisture - related damage to the structure. Its high load - bearing capacity provides additional support to the foundation, protecting buildings from settlement and structural failures.

(2) Environmental Protection

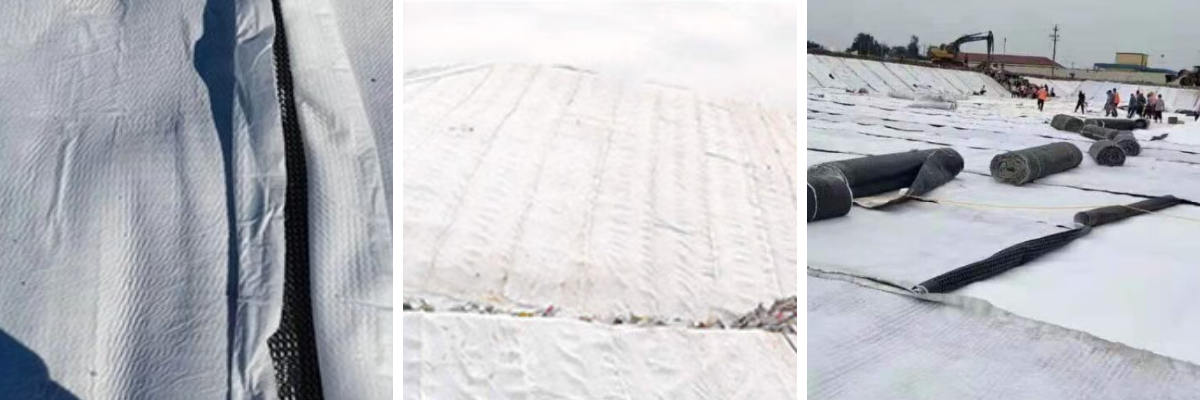

Landfill and Waste Management: As part of landfill lining and leachate collection systems, the composite drainage net helps in the efficient drainage of leachate, preventing groundwater contamination. Its chemical resistance ensures that it can withstand the harsh environment of landfills, while its filtration properties prevent soil and debris from clogging the drainage system.

Coastal and Riverbank Protection: In coastal and riverbank erosion control projects, the net stabilizes the soil and prevents erosion caused by water flow. It can be used in combination with vegetation to create a living barrier that protects the shoreline and riverbanks from the erosive forces of the sea and rivers.

(3) Agricultural and Horticultural Applications

Irrigation and Drainage Systems: In agricultural fields and horticultural settings, the composite drainage net is used to improve irrigation efficiency and prevent waterlogging. It filters out soil particles from irrigation water, protects drainage pipes from blockages, and helps maintain the optimal soil moisture level for plant growth.

Greenhouse and Nursery Management: Inside greenhouses and nurseries, the net can be used for floor drainage, preventing the buildup of excess water that can lead to root rot and other plant diseases. Its easy installation and maintenance make it a convenient choice for these applications.

4. Product Usage Instructions

4.1 Pre-installation Preparation

Site Inspection: Thoroughly check the installation area. Remove any sharp objects like rocks, roots, or debris that could damage the net. Ensure the ground surface is smooth and properly graded to facilitate water flow. If the installation site is on a slope, assess the gradient to determine the best installation orientation for optimal drainage.

Measurement and Planning: Accurately measure the area where the composite drainage net will be installed. Plan the layout, taking into account the direction of water flow, connection points to drainage outlets or pipes, and any obstacles in the area. Calculate the required length and quantity of the net, leaving a small allowance for overlapping during installation.

4.2 Installation Steps

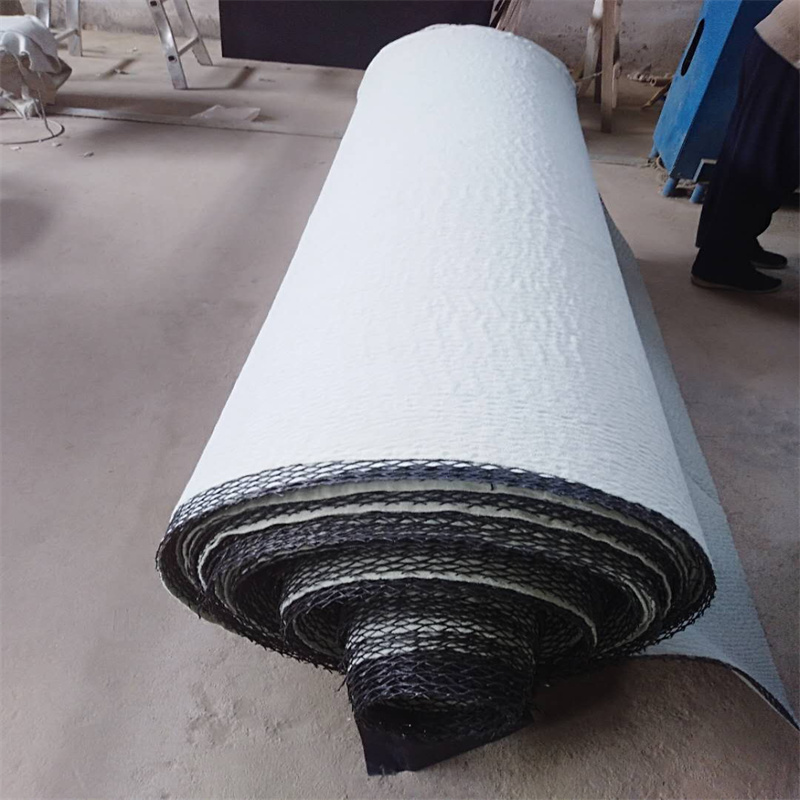

Unrolling the Net: Start unrolling the 220g/6.0mm/220g Composite Drainage Net from one end of the installation area. Unroll it slowly and steadily, ensuring it lies flat and follows the planned layout. If the area is large and requires multiple rolls, position the rolls so that they align properly for seamless connection.

Overlapping and Joining: When connecting two rolls, create an overlap of at least 20 - 30 cm. Use suitable geosynthetic adhesive tapes or stitching methods to secure the overlapping sections. Make sure the adhesive is applied evenly and the stitching is tight to prevent water leakage between the rolls.

Anchoring the Net: Secure the net to the ground at regular intervals. For soil surfaces, use U-shaped landscape staples or pins, inserting them every 50 - 100 cm along the edges and at appropriate intervals across the net. In areas with higher water pressure or where the net may be subject to movement, increase the density of the staples or use additional anchoring methods such as sandbags or concrete blocks at the edges.

Connecting to Drainage Systems: If the composite drainage net is part of a larger drainage system, connect it to drainage pipes, channels, or outlets. Ensure a proper and secure connection to allow water to flow smoothly from the net into the drainage system. Use waterproof connectors or seals to prevent any backflow or leakage at the connection points.

4.3 Post-installation Checks and Maintenance

Initial Inspection: After installation, carefully inspect the entire area to ensure the net is properly laid out, anchored, and connected. Check for any wrinkles, gaps, or loose sections that could affect its performance. Pour a small amount of water on the surface of the net to test the drainage flow and ensure there are no blockages.

Regular Maintenance: Periodically inspect the net, especially after heavy rainfall, extreme weather events, or construction activities in the vicinity. Remove any accumulated debris such as leaves, soil, or sediment from the surface of the net, as this can impede water flow. Check the anchoring points and connections to make sure they remain secure and repair or replace any damaged sections promptly.

For customized 220g/6.0mm/220g Composite Drainage Net solutions tailored to your specific project needs, contact our expert team today. We offer comprehensive technical support, on - site consultation, and flexible product customization options to ensure the success of your project.