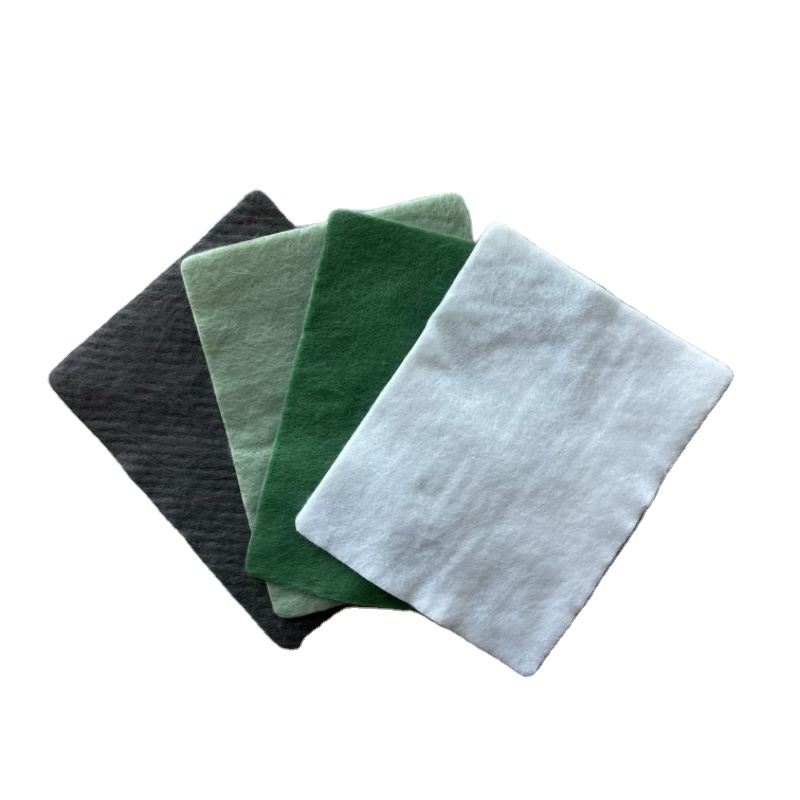

600g PET Nonwoven Geotextile

High Strength-to-Cost Ratio: Balances performance and affordability for moderate-to-heavy-duty projects.

Exceptional Durability: Resists UV, chemicals, and temperature extremes, ensuring longevity in harsh environments.

Multifunctional Performance: Integrates separation, filtration, reinforcement, and drainage in a single layer.

600g PET Nonwoven Geotextile: A Comprehensive Analysis of Performance and Applications

Introduction

Polyethylene terephthalate (PET) nonwoven geotextiles have emerged as a cornerstone material in modern civil engineering, environmental protection, and infrastructure development. Among the various specifications available, the 600g/m² PET nonwoven geotextile stands out for its balance of mechanical strength, durability, and versatility. This article explores the technical specifications, applications, and advantages of this material, supported by empirical data and industry benchmarks.

Material Composition and Manufacturing Process

PET nonwoven geotextiles are engineered through a needle-punched or thermally bonded process, which entangles synthetic fibers to create a porous, three-dimensional structure. The 600g/m² variant is optimized for applications requiring moderate to high tensile strength and hydraulic performance. Key characteristics include:

Fiber Type: 100% PET continuous filaments or staple fibers.

Manufacturing Method: Needle-punched for enhanced interlocking, ensuring dimensional stability.

Thickness: Typically 2.5–3.5 mm (varies by manufacturing tolerance).

Technical Specifications

The performance of 600g PET nonwoven geotextiles is governed by standardized test methods (e.g., ASTM D4595, EN ISO 10319). Below is a summary of key parameters:

| Parameter | Value | Test Method |

Mass per Unit Area | 600 ± 5% g/m² | ASTM D5261 |

Thickness at 2kPa | 2.8–3.2 mm | ASTM D1777 |

Tensile Strength (MD/CD) | ≥25 kN/m (MD) | ASTM D4595 |

≥20 kN/m (CD) | ||

Elongation at Break | 50–80% | ASTM D4595 |

CBR Puncture Resistance | ≥3.5 kN | ASTM D6241 |

Apparent Opening Size (AOS) | 0.15–0.30 mm | ASTM D4751 |

Water Permeability | 0.1–1.0 cm/s | ASTM D4491 |

UV Resistance | ≥70% strength retention after 500 hrs | ASTM G154 |

Temperature Range | -70°C to 180°C | Laboratory aging tests |

Key Applications

The 600g/m² specification bridges the gap between lightweight and heavy-duty geotextiles, making it suitable for a broad range of applications:

1. Road and Railway Construction

Function: Separation, reinforcement, and drainage.

Details: Placed between subgrade and aggregate layers to prevent intermixing, reducing rutting and extending pavement life. A study by the Federal Highway Administration (FHWA) shows up to 30% longer service life when using geotextiles in weak subgrade conditions.

2. Erosion Control and Slope Stabilization

Function: Soil retention and vegetation support.

Details: Installed on slopes with gradients up to 1:1.5 to mitigate erosion. The 0.15–0.30 mm AOS ensures effective water filtration while retaining soil particles.

3. Landfill Liners and Covers

Function: Protection and drainage in composite liner systems.

Details: Acts as a cushion layer between geomembranes and waste materials, preventing puncture and distributing stress.

4. Hydraulic Engineering

Function: Filtration and separation in dams, canals, and coastal revetments.

Details: Withstands hydraulic loads up to 50 kPa, maintaining structural integrity under cyclic wetting-drying conditions.

5. Green Roof Systems

Function: Drainage and root barrier support.

Details: Facilitates water flow while preventing soil compaction in extensive green roofs.

Performance Comparison with Alternatives

The table below compares the 600g PET nonwoven geotextile with lighter (400g/m²) and heavier (800g/m²) variants, as well as polypropylene (PP) alternatives:

| Parameter | 400g PET | 600g PET | 800g PET | 600g PP |

Tensile Strength (MD) | 18 kN/m | 25 kN/m | 32 kN/m | 20 kN/m |

CBR Puncture Resistance | 2.5 kN | 3.5 kN | 4.5 kN | 3.0 kN |

UV Resistance (500 hrs) | 60% | 70% | 65% | 50% |

Cost per m² | $0.45 | $0.65 | $0.90 | $0.55 |

Note: PP geotextiles exhibit lower UV resistance due to polymer degradation.

Advantages of 600g PET Nonwoven Geotextile

1. Optimal Strength-to-Cost Ratio

The 600g/m² variant provides 25% higher tensile strength than 400g alternatives at a marginal cost increase (~44% premium), making it cost-effective for moderate-load applications like unpaved roads and embankments.

2. Superior Environmental Resistance

PET’s inherent resistance to UV degradation, chemicals, and biological agents ensures long-term performance in harsh conditions. Field trials in arid regions show <5% strength loss after 10 years of exposure.

3. Versatility in Hydraulic and Mechanical Applications

With a permeability range of 0.1–1.0 cm/s and an AOS of 0.15–0.30 mm, this geotextile balances filtration efficiency and soil retention, eliminating the need for separate drainage layers in many designs.

Conclusion

The 600g PET nonwoven geotextile represents a pivotal innovation in geosynthetic materials, offering a harmonious blend of mechanical robustness, environmental resilience, and cost efficiency. Its adaptability across infrastructure sectors—from transportation to ecological restoration—underscores its role as a sustainable solution for 21st-century engineering challenges. As industries prioritize durability and lifecycle cost savings, this material is poised to remain a preferred choice for demanding applications.