HDPE Geomembrane For Tailing

1.Excellent Chemical Resistance – Resists acids, alkalis, and hazardous leachates commonly found in tailings, ensuring long-term protection.

2.Superior Puncture and Tear Resistance – Withstands sharp waste materials and rough subgrades typically present in mining environments.

3.UV and Weather Resistant – Maintains structural integrity under prolonged exposure to sunlight and extreme climates.

4.Low Permeability – Provides outstanding containment with minimal seepage, critical for environmental protection.

5.Durable and Long Service Life – Engineered for decades of reliable performance in harsh tailings pond conditions.

6.Flexible Installation – Easy to weld and deploy across uneven terrains, slopes, and large surface areas.

HDPE Geomembrane For Tailing

In modern mining operations, environmental sustainability and waste containment are critical concerns. One of the most effective and widely adopted materials for tailings pond lining is the High-Density Polyethylene (HDPE) geomembrane. This synthetic barrier is engineered to provide exceptional performance in aggressive tailings environments. With a balance of mechanical strength, chemical resistance, and cost efficiency, HDPE geomembranes have become the material of choice for tailings dam and slurry containment applications around the globe.

Understanding Tailings and Containment Challenges

Tailings are the by-products of extracting valuable minerals from ore. After the minerals are separated, the leftover finely ground rock and process effluents are stored in engineered structures known as tailings ponds. These ponds can contain a wide range of potentially harmful substances, including heavy metals, residual process chemicals, and acidic water. Without proper containment, tailings pose a significant risk to groundwater, surrounding ecosystems, and human health.

To address these risks, robust containment systems are required. HDPE geomembranes offer a proven solution with their impermeable properties and high resistance to the stresses typically encountered in mining waste applications.

Key Advantages of HDPE Geomembrane in Tailing Ponds

1. Exceptional Chemical Stability

Tailings ponds often contain aggressive substances such as cyanide, arsenic, and sulfuric acid, all of which can rapidly degrade traditional lining materials. HDPE geomembranes are formulated to resist a broad spectrum of chemical agents. Their non-polar polymer structure makes them inherently resistant to corrosion, decomposition, and chemical attack, even in the most acidic or alkaline environments.

This chemical resilience ensures long-term environmental protection and reduces the need for frequent liner replacement or maintenance.

2. Outstanding Mechanical Strength

In mining applications, geomembranes must withstand significant mechanical stress — from the weight of tailings slurry to potential movement in the foundation. HDPE liners are known for their high tensile strength, elongation capacity, and excellent tear resistance. These properties enable them to maintain integrity even when subjected to uneven loads or settlement.

Their puncture resistance is particularly valuable in areas where angular rock fragments and abrasive materials are prevalent.

3. Low Permeability for Maximum Containment

The primary function of a geomembrane is to prevent leakage. HDPE geomembranes have an extremely low permeability rate, making them ideal for lining tailings ponds and impoundments. This ensures minimal seepage of contaminants into the surrounding soil and groundwater.

Moreover, when installed with proper welding and quality assurance, HDPE liners form a seamless barrier that exceeds environmental regulatory standards.

4. UV and Thermal Resistance

Tailings storage facilities are often located in remote, open areas with prolonged exposure to sunlight and temperature fluctuations. HDPE geomembranes are specifically stabilized with carbon black and antioxidants to resist ultraviolet degradation. This UV resistance, combined with their excellent thermal stability, allows HDPE liners to perform reliably in both extremely hot and cold climates.

They remain flexible at low temperatures and do not become brittle or crack under thermal cycling, making them suitable for a wide range of geographical regions.

5. Ease of Installation and Long Lifespan

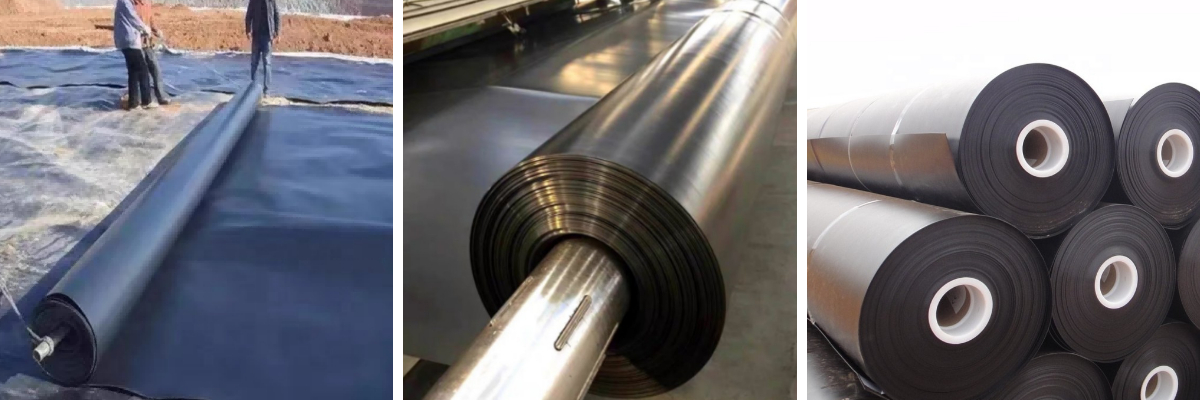

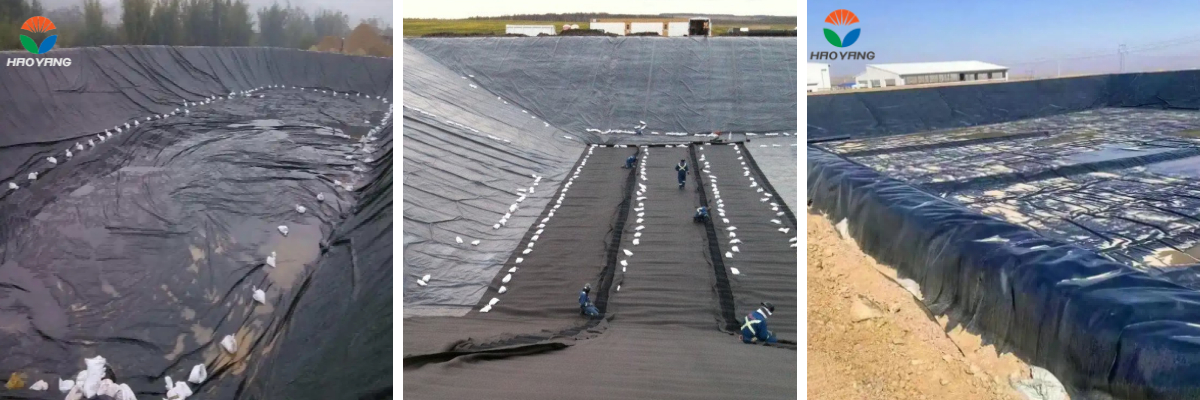

Despite their strength, HDPE geomembranes are relatively lightweight and flexible, making transportation and deployment efficient. On-site installation is typically performed using heat fusion welding techniques, which create strong, watertight seams.

When properly installed and protected from mechanical damage, HDPE geomembranes can last for over 30 years, making them a highly cost-effective long-term solution for tailings containment.

6. Compatibility with Composite Liner Systems

In high-risk tailings projects, HDPE liners are often used in conjunction with geosynthetic clay liners (GCLs) or drainage geonets to form composite barrier systems. This combination significantly enhances containment performance by providing both chemical and physical protection layers.

HDPE’s compatibility with other geosynthetic materials allows it to integrate seamlessly into multilayered designs, optimizing site safety and regulatory compliance.

Applications in the Mining Industry

HDPE geomembranes are used across a wide range of tailings management facilities, including:

1.Tailings Dams: To prevent seepage from the main tailings body into groundwater.

2.Slurry Lagoons: For temporary storage and evaporation of mineral processing fluids.

3.Heap Leach Pads: In combination with other liners to contain aggressive leachate.

4.Secondary Containment Basins: To collect spills and prevent cross-contamination.

Each of these applications benefits from HDPE’s robustness, resistance, and design versatility.

Why Choose Haoyang's HDPE Geomembrane?

At Haoyang Environmental Co., Ltd., we specialize in the development and manufacturing of premium-grade HDPE geomembranes for industrial and environmental use. Our tailings pond liners are produced from 100% virgin HDPE resins and comply with global standards such as GRI-GM13.

Key benefits of choosing Haoyang include:

1.Factory-direct pricing with strict quality control

2.Customized thicknesses from 0.5mm to 3.0mm

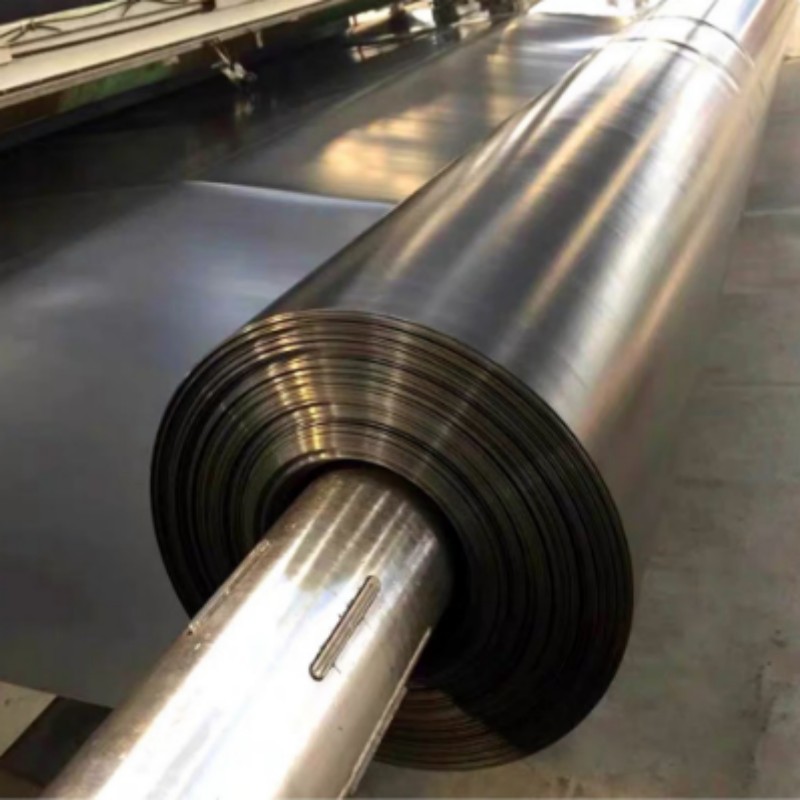

3.Advanced extrusion and calendering production lines

4.On-site technical support and welding training

5.Successful case studies across Asia, Africa, and Latin America

Whether for greenfield mining projects or tailings dam upgrades, Haoyang delivers reliable geomembrane solutions tailored to each client’s environmental and engineering needs.

Environmental and Regulatory Compliance

Governments and international institutions are increasingly enforcing stricter regulations on tailings management. HDPE geomembranes are a critical component in helping mining companies meet these standards, such as those outlined by the International Council on Mining and Metals (ICMM) and the Global Industry Standard on Tailings Management (GISTM).

By incorporating HDPE liners into their containment strategy, mining operators demonstrate a commitment to environmental stewardship and sustainable development.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

As the mining industry continues to evolve, so too must the technologies that support safe and responsible operations. HDPE geomembranes provide a robust, versatile, and environmentally sound solution for managing mine tailings. Their superior chemical resistance, mechanical performance, and long service life make them a smart investment for tailings containment worldwide.

For any mining operation seeking dependable environmental protection, HDPE geomembranes are not just a choice—they are the standard.