Polyester Geogrid

1.High Tensile Strength – Excellent reinforcement in both longitudinal and transverse directions.

2.Low Creep Performance – Maintains dimensional stability under long-term loading.

3.Superior Flexibility – Adapts well to irregular subgrades and curved surfaces.

4.Resistant to Biological and Chemical Degradation – Performs well in various soil and environmental conditions.

5.Improves Bearing Capacity – Enhances soil strength and reduces settlement in soft ground.

6.Easy Installation – Lightweight and rollable, reducing transportation and labor costs.

Polyester Geogrid

In the ever-evolving field of civil and geotechnical engineering, the need for high-performance, durable, and cost-effective reinforcement materials is paramount. Among the many types of geosynthetics available today, Polyester Geogrid stands out as a reliable solution for soil stabilization, pavement support, and structural reinforcement in various construction applications.

Designed to deliver strength, durability, and adaptability, polyester geogrid has become an essential material for engineers and contractors working in challenging environments. Its superior mechanical properties, coupled with ease of installation and long-term performance, make it an indispensable part of modern infrastructure development.

What is Polyester Geogrid?

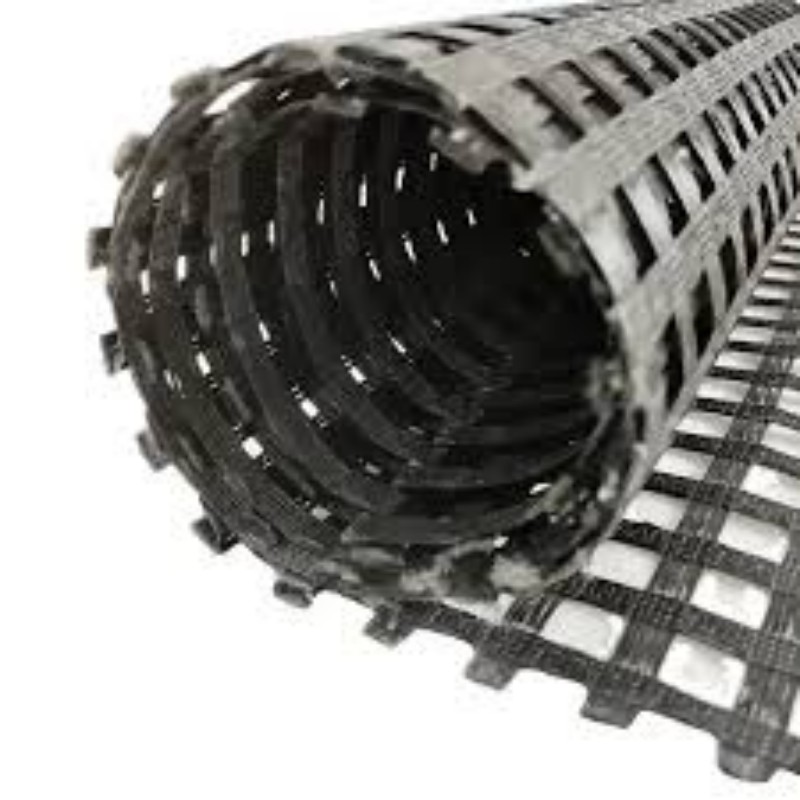

Polyester Geogrid is a type of geosynthetic reinforcement made from high-strength polyester yarns, woven or knitted into a grid structure and coated with a protective polymer layer, such as PVC or bitumen. The coating enhances resistance to environmental degradation, chemical attack, and UV exposure, ensuring long-term durability in diverse conditions.

Unlike traditional construction reinforcements, polyester geogrid provides high tensile strength at low elongation, making it particularly effective in reinforcing soft soils, embankments, retaining walls, and road foundations.

Key Advantages of Polyester Geogrid

1. High Tensile Strength and Low Elongation

Polyester geogrid offers excellent tensile strength in both longitudinal and transverse directions, which significantly improves the load-bearing capacity of soils. This strength, combined with low elongation, ensures structural stability and minimizes deformation over time.

2. Outstanding Creep Resistance

One of the critical concerns in long-term geotechnical applications is creep — the slow, permanent deformation of materials under constant load. Polyester geogrid demonstrates exceptionally low creep, even under sustained pressure, making it ideal for use in retaining structures and load-bearing applications.

3. Superior Flexibility and Workability

Thanks to its woven or knitted structure, polyester geogrid is highly flexible, allowing it to conform to complex ground contours and irregular surfaces. This adaptability makes installation faster and more efficient, particularly on curved or sloped areas.

4. Chemical and Biological Resistance

The polyester core and polymer coating make the geogrid resistant to acids, alkalis, and microbial degradation. As a result, it performs reliably in a wide range of soil types and environmental conditions, including areas with high moisture content or industrial pollutants.

5. Lightweight and Cost-Effective

Compared to steel or other traditional reinforcements, polyester geogrid is lightweight and easy to transport, reducing shipping costs and labor requirements on-site. Its cost-effectiveness, coupled with long service life, provides an excellent return on investment.

6. Improves Stability and Reduces Maintenance

By enhancing the load distribution and reducing differential settlement, polyester geogrid helps maintain the integrity of roads, embankments, and slopes over time. This leads to fewer maintenance interventions and longer service intervals for critical infrastructure.

Common Applications of Polyester Geogrid

Thanks to its versatility and superior performance, polyester geogrid is used in a wide variety of civil engineering and construction projects, including:

1.Retaining walls and reinforced slopes – Provides structural support and prevents collapse or erosion.

2.Roadbed reinforcement – Enhances bearing capacity and reduces rutting and settlement in pavements.

3.Railway subgrade reinforcement – Ensures stable support under dynamic and heavy loads.

4.Embankment construction over soft soils – Prevents failure due to weak foundation soils.

5.Landfills and waste containment – Improves stability of liners and caps.

6.Foundation reinforcement – Supports shallow or poorly compacted foundations.

Its performance under diverse conditions makes it suitable for both new construction and rehabilitation projects.

Manufacturing Excellence with Haoyang Environmental Co., Ltd.

One of the most trusted names in the field of geosynthetics is Haoyang Environmental Co., Ltd., a leading manufacturer based in China with a global footprint. Haoyang is renowned for producing high-quality polyester geogrids that meet international standards for strength, consistency, and environmental safety.

Why Choose Haoyang's Polyester Geogrid?

1.100% Virgin Polyester Yarn

Haoyang uses only virgin raw materials, ensuring the structural integrity and consistent quality of the geogrid. This makes it suitable for demanding applications that require dependable performance.

2. Precise Engineering and Customization

With advanced weaving and coating technologies, Haoyang offers customizable grid dimensions, tensile strengths, and coatings tailored to specific project requirements. Clients can choose from PVC, bitumen, or other protective coatings based on environmental needs.

3. Rigorous Quality Control

Every roll of polyester geogrid undergoes strict testing for tensile strength, elongation, coating adhesion, and dimensional accuracy. Haoyang is certified under ISO 9001 and other international standards, ensuring quality you can trust.

4. Global Delivery and Project Support

Haoyang’s products have been successfully exported to over 50 countries, supporting infrastructure development in Southeast Asia, the Middle East, Africa, and South America. The company offers technical support, documentation, and on-site guidance to help clients achieve the best results.

Case Studies: Real-World Performance

1.Mountain Road Reinforcement in Central Asia: Polyester geogrid from Haoyang was used to stabilize a slope-prone road network. The geogrid helped reduce erosion and sliding, maintaining road safety during the rainy season.

2.Highway Foundation in Southeast Asia: In a project involving construction on soft clay, Haoyang's geogrid was used for base reinforcement. The result was improved load distribution and reduced settlement, extending the pavement life by several years.

3.Urban Retaining Wall in Africa: For a large urban development, polyester geogrid provided backfill reinforcement in a segmental retaining wall system. It allowed for taller structures without increasing the footprint, saving valuable urban space.

The Future of Reinforcement Technology

As infrastructure needs continue to expand globally, especially in regions with challenging soils and climates, materials like polyester geogrid will play an increasingly important role. Innovation is also moving forward—Haoyang is currently investing in the development of composite geogrids, multi-layer reinforcements, and eco-friendly coatings to meet future demands.

With their combination of strength, adaptability, and environmental resilience, polyester geogrids represent the next generation of geotechnical reinforcement solutions.

Item | Description |

Product Name | Polyester Geogrid |

Material | High-tenacity polyester yarn with polymer coating (PVC/Bitumen/Customized) |

Structure | Biaxial or uniaxial grid |

Tensile Strength | 20–800 kN/m (customizable) |

Elongation at Break | < 10% (typically 8%) |

Creep Resistance | Excellent under long-term loading |

Coating | PVC, Bitumen, or Customized Polymer Coating |

Roll Width | 1.0 m – 6.0 m (standard: 3.95 m) |

Roll Length | 50 m – 100 m (customizable) |

Color | Black (standard) or customized |

UV Resistance | Enhanced with anti-UV additives |

Chemical Resistance | High resistance to acid, alkali, and microbial degradation |

Installation | Lightweight and easy to deploy |

Application Areas | Road base reinforcement, retaining walls, embankments, soft soil stabilization |

Certifications | ISO 9001, CE, ASTM D6637, SGS |

Raw Material Source | 100% virgin polyester yarn |

Packaging | PE film wrapped with woven bag or customized |

Lead Time | 7–15 working days |

Export Markets | Asia, Middle East, Africa, Europe, South America |

Supplier Highlights | Source factory, OEM service, 24/7 support, global project experience |

Polyester Geogrid is not just a reinforcement material—it's a strategic solution to many of the challenges faced in modern civil engineering. Its unique combination of high tensile strength, low elongation, chemical resistance, and flexibility makes it ideal for improving the performance and durability of roads, walls, railways, and more.

When choosing a polyester geogrid for your next project, Haoyang Environmental Co., Ltd. offers not only superior products but also trusted expertise and comprehensive support. With a proven track record and a commitment to innovation, Haoyang is reinforcing the future—one grid at a time.