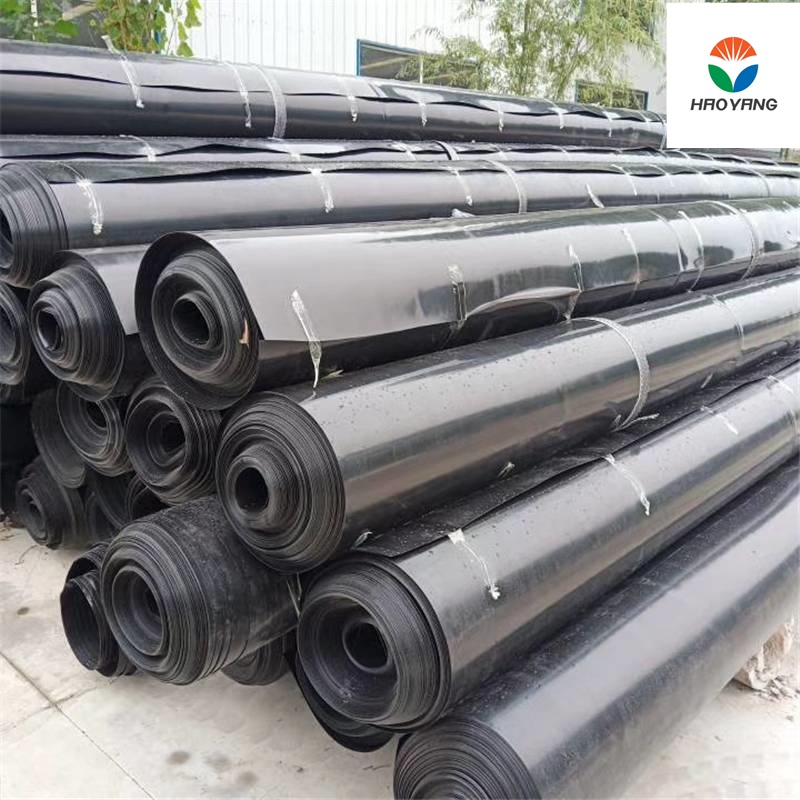

0.75mm HDPE Liner

1.Excellent durability: 0.75mm HDPE Liner. With its high-strength polyethylene material, it exhibits extremely strong physical resistance. Under the influence of ultraviolet rays and oxidation, its performance decays slowly, allowing for long-term stable use in harsh environments.

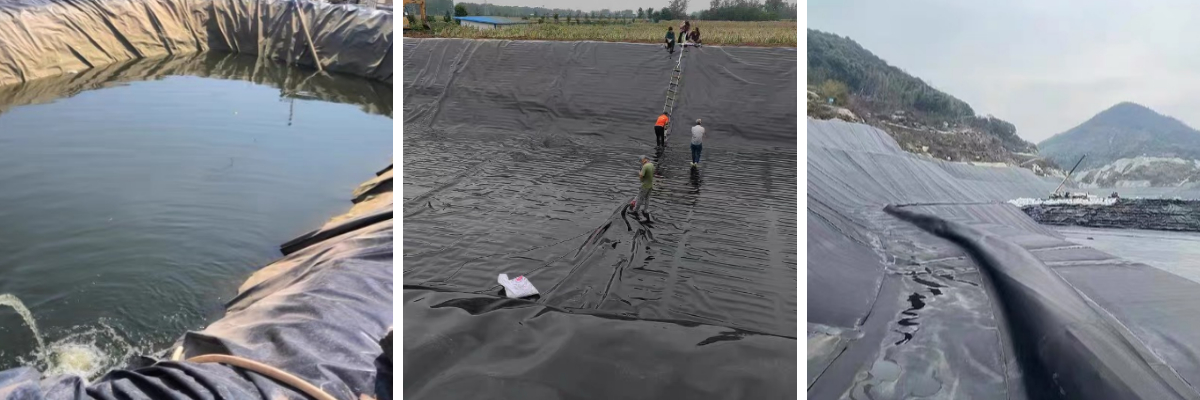

2.Top anti-seepage performance: The high-density structure endows this liner with excellent anti-seepage characteristics, effectively preventing the penetration of various liquids and gases. This ensures environmental safety and prevents pollution from spreading.

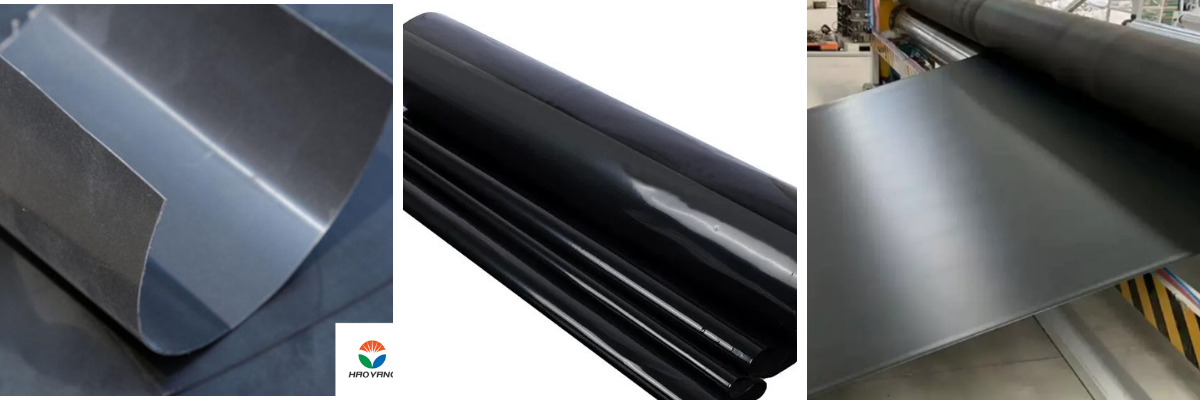

3.Convenient construction features: Despite a thickness of only 0.75mm, it is flexible in texture, making it easy to cut, weld, and lay. At the same time, its welding process is mature, with strong welds, ensuring the overall anti-seepage effect and improving construction efficiency.

4.Ultra-high cost-effectiveness: Considering both comprehensive performance and cost, 0.75mm HDPE Liner has significant advantages. The construction is convenient and saves labor costs, achieving a perfect balance between performance and economy.

Product Introduction

0.75mm HDPE Liner is made of high-density polyethylene (HDPE) as the core material. It is produced by polymerization of ethylene monomers. The molecular chain is linearly compact and has a high crystallinity (80%-95%), with a density of 0.941-0.965g/cm³. The raw materials are pure and do not contain easily migratable additives. Through the extrusion and lamination process, a uniform 0.75mm thick layer is formed, featuring high strength, resistance to chemical corrosion and excellent anti-seepage properties.

Product parameters

Parameter | Value/Description |

Thickness | 0.75 mm (0.03 inch) |

Material | High-Density Polyethylene (HDPE) |

Density | 0.941–0.965 g/cm³ |

Tensile Strength (MD/TD) | ≥25 MPa (Machine Direction/Transverse Direction) |

Elongation at Break | ≥700% |

Puncture Resistance | ≥250 N (ASTM D6241) |

Chemical Resistance | Excellent resistance to acids, alkalis, salts, and organic solvents |

Service Temperature | -70°C to +60°C (-94°F to +140°F) |

UV Resistance | Long-term durability with UV stabilizers (≥5 years outdoor exposure) |

Seam Strength | ≥85% of base material strength (welded joints) |

Certifications | May comply with ASTM D3763, ISO 14685, etc. |

Case Analysis

1.Belize Aquaculture Farm: In Belize, farmers use 0.75mm HDPE Liner to construct ponds. As reported by Robins P. McIntosh in 2000, it effectively reduces the erosion of pond banks, shortens the turnover time between farming seasons, stabilizes water levels, and significantly improves the overall farming efficiency of the ponds, thereby boosting the output of aquatic farming.

2.Panama's Agromarina Farm: In 2001, Bray et al. reported that in the Agromarina de Panama farm in Panama, earthen ponds were affected by the White Spot Syndrome Virus (WSSV), resulting in a sharp decline in production. After using 0.75mm HDPE geotextile membrane lining, the survival rate of pond-cultured organisms increased from 9% in earthen ponds to 80%, significantly improving the farming conditions.

3.Indonesia East Java Region: In 2002, N. Taw et al. conducted research and found that in ponds in the East Java region that used 0.75mm HDPE Liner, the farming productivity increased from 3634 kilograms per hectare in earthen ponds to 10094 kilograms per hectare, achieving a significant increase in farming benefits and promoting the development of local aquaculture.

4.Peruvian Pond Project: Some ponds in Peru selected 0.75mm black HDPE anti-seepage liners. This liner, with the anti-puncture, impact-resistant, and tear-resistant properties of HDPE material, effectively maintains the stability of the pond structure and water quality in the complex climate and water conditions of Peru, ensuring a healthy growth environment for fish.

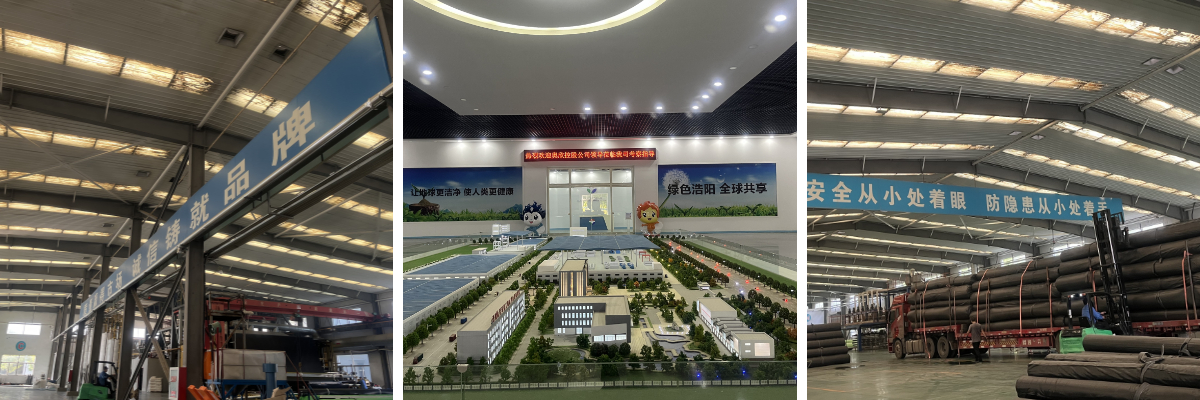

Why choose Haoyang Environment?

Haoyang Environment has an advanced geotextile membrane production line. Its 10-meter wide blown film production line adopts a five-layer co-extrusion technology, achieving nitrogen roughening and online double-sided roughening, which is a world-first innovation. Currently, there are 2 blown film production lines and 2 flat extrusion production lines, with strong production capacity. The product specifications are diverse, capable of meeting the needs of various fields such as environmental protection and water conservancy, and providing reliable anti-seepage protection for various projects.