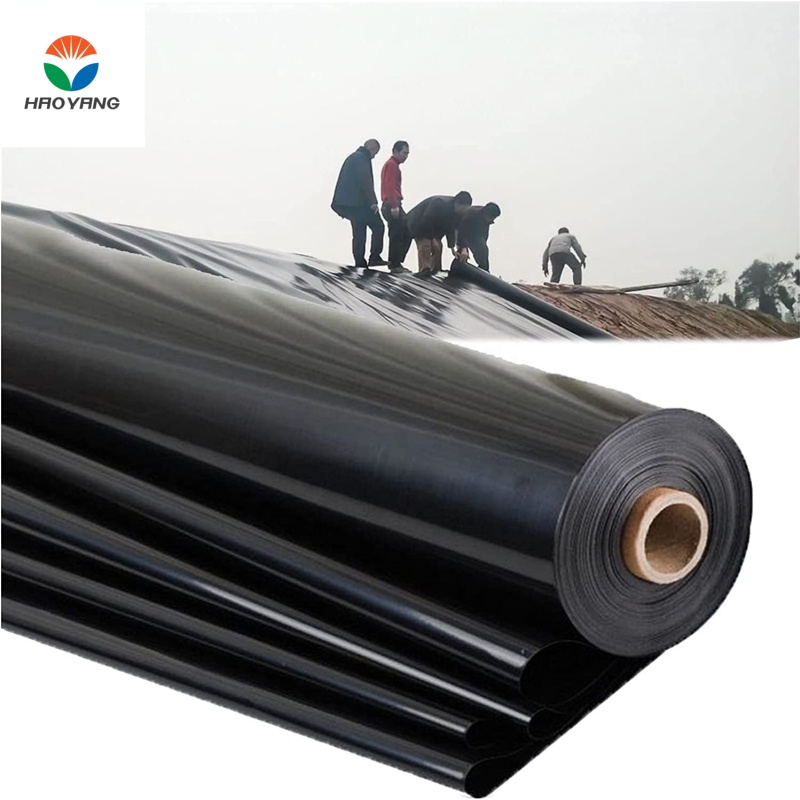

1.5mm HDPE Liner

1. Superb anti-seepage capability: With a 1.5mm thickness of reinforced HDPE molecularly dense structure, the permeability coefficient is as low as ≤10⁻¹³ cm/s, capable of blocking complex media such as heavy metal ions and chemical waste liquids.

2. Excellent stress resistance: Tensile strength ≥ 30MPa (both longitudinal and transverse), elongation at break ≥ 700%, able to withstand base settlement and soil stress deformation, maintaining structural stability in complex terrain.

3. Extreme environmental adaptability: Resistant to temperature differences of -70°C to +60°C, resistant to UV aging (with 5% carbon black and antioxidants added), with a service life of over 50 years in open-air conditions, suitable for harsh climate regions .

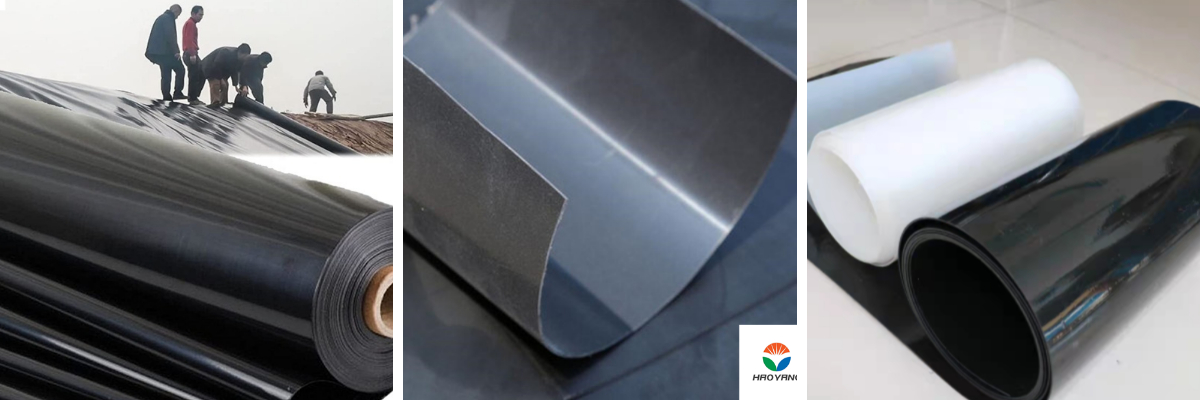

4. Construction efficiency and reliability: Width can reach 8-10 meters, reducing weld joint connections, combined with dual-track hot-melt welding technology, the joint strength reaches over 90% of the base material.

Product Introduction

1.5mm HDPE Liner is made of high-density polyethylene (HDPE) as the base material. The ethylene monomer undergoes polymerization to form linear and compact molecular chains, with a crystallinity of 80%-95% and a density of 0.941-0.965g/cm³. By adding 5% carbon black, antioxidants, and light stabilizers, the product's resistance to ultraviolet rays and aging is enhanced. The product has uniform thickness, a tensile strength of ≥30MPa, a elongation at break of ≥700%, a permeability coefficient of ≤10⁻¹³ cm/s, and is suitable for harsh anti-seepage scenarios such as landfill sites and tailings ponds, providing long-term environmental protection protection.

Product parameters

Parameter | Value/Description |

Thickness | 1.5 mm (0.059 inch) |

Material | High-Density Polyethylene (HDPE) |

Density | 0.941–0.965 g/cm³ |

Tensile Strength (MD/TD) | ≥30 MPa (Machine/Transverse Direction) |

Elongation at Break | ≥700% |

Puncture Resistance | ≥350 N (ASTM D6241) |

Osmotic Coefficient | ≤1×10⁻¹³ cm/s |

Service Temperature | -70°C to +60°C (-94°F to +140°F) |

UV Resistance | ≥50 years (with 5% carbon black & stabilizers) |

Seam Strength | ≥90% of base material strength |

Standard Compliance | ASTM D3763, ISO 14685, GRI-GM13 |

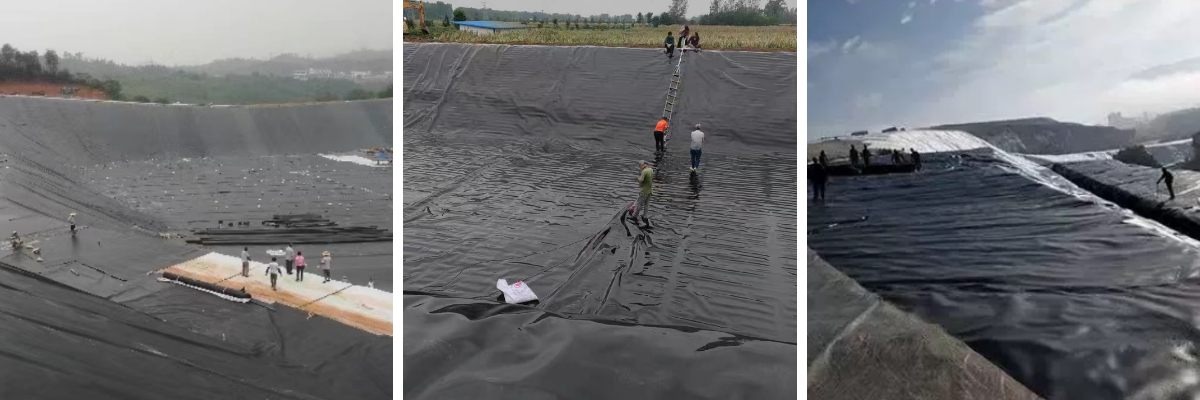

The application of 1.5mm HDPE Liner worldwide

Case 1: A reservoir project in Australia

In a certain area of Australia, to address the irrigation and domestic water supply issues for surrounding farmlands, a reservoir was planned to be constructed. The local soil was mostly composed of sandstone, with deep and interlaced cracks, large gaps, and mixed rocks, resulting in extremely poor water retention capacity. Through experiments, water easily seeped into the soil through the cracks. Additionally, the area had a temperate continental climate with little precipitation, high summer temperatures, strong evaporation, and the eastern mountains blocking moisture, leading to inland aridity.

Based on these circumstances, the project team selected 1.5mm HDPE Liner. Its thickness provided reliable anti-seepage protection, and it was also treated with anti-ultraviolet and anti-aging agents, enabling it to adapt to outdoor environments. During construction, professional welding equipment was used to lay it at the bottom of the reservoir, and the weld seams were strictly processed to ensure a secure connection. After the project was completed, it effectively prevented water infiltration and ensured the water supply.

Case 2: A landfill project in Thailand

In some areas of Thailand, improper waste management led to the contamination of groundwater by landfill leachate, threatening the environment and health. Therefore, the government initiated a related governance project. During the construction of a certain landfill site, 1.5mm HDPE Liner was selected. This material had strong anti-seepage properties and could prevent landfill leachate from seeping. Its chemical stability was good, capable of resisting the erosion of harmful substances in the garbage.

Before construction, the site's base was leveled and cleaned, removing sharp objects. During construction, HDPE Liner was laid in a specific direction, minimizing weld seams. The hot-melt welding technique was used to ensure weld strength. After completion, it significantly reduced the infiltration of external water such as rain into the landfill area, controlled the emission of odors and flammable gases, and reduced pollution risks.

Case 3: A wastewater treatment pool project in the United States

In a certain city in the United States, to upgrade the wastewater treatment system, multiple wastewater treatment pools were built. As the treatment process involved various corrosive chemical substances, the requirements for pool anti-seepage and chemical corrosion resistance were extremely high. 1.5mm HDPE Liner became the ideal choice, as its high-density polyethylene material could resist acid and alkali and other chemical substances' erosion, and its 1.5mm thickness ensured long-term stable anti-seepage effect.

During construction, the pool dimensions were precisely measured, and the laying plan was planned in advance. Skilled welders operated the welding equipment, ensuring the tight connection of each piece of HDPE Liner. After completion, strict testing was conducted, and no leakage occurred, ensuring the efficient operation of the wastewater treatment system and preventing chemical substance leakage from polluting the surrounding soil and water bodies.

Case 4: A mining tailings reservoir project in Brazil

In the tailings reservoir construction of a certain mining area in Brazil, 1.5mm HDPE Liner was used. The tailings contained harmful substances such as heavy metals, and if leaked, would cause great harm. The high strength and puncture resistance of HDPE Liner could withstand the pressure of tailings accumulation and prevent them from being punctured by sharp tailings particles. The 1.5mm thickness enhanced the anti-seepage performance, effectively preventing the leakage of harmful substances.

The construction process followed strict standards, starting with compacting and leveling the bottom of the reservoir, and then laying HDPE Liner in an orderly manner. For complex terrain and corner areas, precise cutting and welding were carried out. After completion, long-term monitoring showed that the tailings reservoir was operating well, without any leakage accidents, effectively protecting the surrounding environment.

Where does Haoyang Environment's advantage lie?

Haoyang Environmental's production of 1.5mm HDPE Liner has remarkable advantages. Firstly, the process is advanced, adopting the international leading five-layer co-extrusion technology, combined with nitrogen roughening and online double-sided roughening processes, which enhances friction and stability. Secondly, the equipment is excellent, with 2 blow molding and 2 flat extrusion production lines ensuring product quality, and equipped with online monitoring and electrical spark detectors to strictly control quality. Thirdly, the materials are of high quality, using virgin resin to ensure anti-seepage, anti-aging and other properties, meeting the strict requirements of multiple fields.