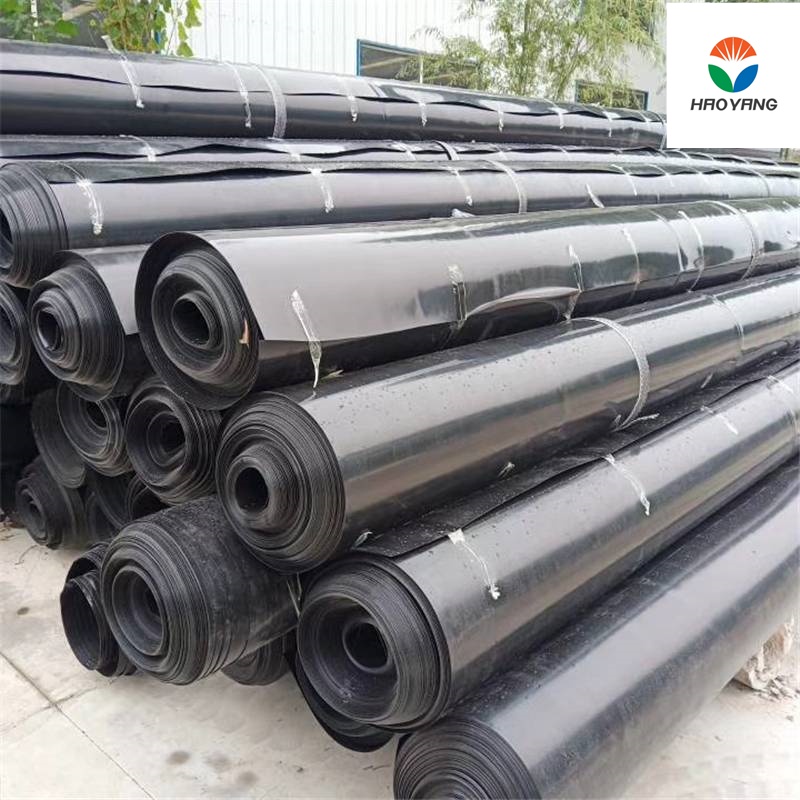

1mm HDPE Geomembrane Liner For Tailings

1.Outstanding anti-seepage performance: The 1mm HDPE geotextile membrane has an extremely low permeability, which can effectively prevent the infiltration of harmful chemicals and heavy metals in the tailings,

2.Superior durability: Made of high-quality high-density polyethylene material, it has excellent resistance to ultraviolet rays, acid and alkali corrosion, and aging performance.

3.Convenient construction and installation: The product has an appropriate thickness and good flexibility, making it easy to transport, cut, and weld.

4.High cost-effectiveness guarantee: It combines excellent performance with reasonable price. With a long service life and reliable protective effect.

Product Introduction

1mm HDPE tailings anti-seepage membrane is made from high-quality high-density polyethylene. It has excellent anti-seepage performance with extremely low permeability, effectively preventing the infiltration of harmful substances from tailings. It possesses strong resistance to ultraviolet rays, acid and alkali corrosion, and aging, and can work stably in complex environments for a long time. The thickness and flexibility are well-matched, making it convenient for construction. It is a reliable choice for ensuring environmental safety and reducing maintenance costs in tailings treatment.

Product parameters

Parameter | Specification | Significance/Function |

Material | High-Density Polyethylene (HDPE) | Provides chemical resistance, durability, and flexibility for long-term performance. |

Thickness | 1mm (±5% tolerance) | Ensures optimal balance between strength, flexibility, and cost for tailings containment. |

Tensile Strength | ≥25 MPa (MD), ≥20 MPa (TD) | Offers resistance against stretching during installation and operational stress. |

Elongation at Break | ≥700% (MD), ≥700% (TD) | Allows the geomembrane to adapt to ground movement without tearing. |

Puncture Resistance | ≥500 N | Protects against damage from sharp objects in tailings or underlying surfaces. |

Permeability | ≤1×10⁻¹³ cm/s | Minimizes seepage, preventing contamination of surrounding soil and groundwater. |

UV Resistance | Excellent (≥2000 hours in Xenon test) | Ensures long-term durability under sunlight exposure during and after installation. |

Chemical Resistance | Resistant to acids, alkalis, salts | Withstands corrosive substances in tailings, maintaining structural integrity. |

Operating Temperature | -70℃ to +70℃ | Functions effectively in extreme cold and hot environments, ensuring year-round reliability. |

Weld Strength | ≥85% of base material strength | Guarantees secure seams for continuous and reliable containment. |

The price range of 1mm geomembrane

The price of 1mm HDPE geotextile membrane varies due to various factors. It generally ranges from 0.3 to 3.8 US dollars per square meter. The FOB price of 1mm HDPE geomembrane is 0.81 to 1.98 US dollars per square meter.

Influencing factors

1.Raw materials: The geomembrane produced from new materials has excellent performance and a high price; while the one made from recycled materials has a lower price.

2.Production process: Products produced by advanced technology have superior performance and quality, and the corresponding prices are also higher.

3.Product indicators: The higher the indicators such as tensile strength and puncture resistance, the stricter the production requirements are, and the higher the price will be.

4.Market supply and demand: During peak seasons, demand is high and prices rise; during off-peak seasons, supply exceeds demand, and prices may drop.

5.Brand after-sales: Well-known brands have good quality and excellent service, and their prices are often higher.

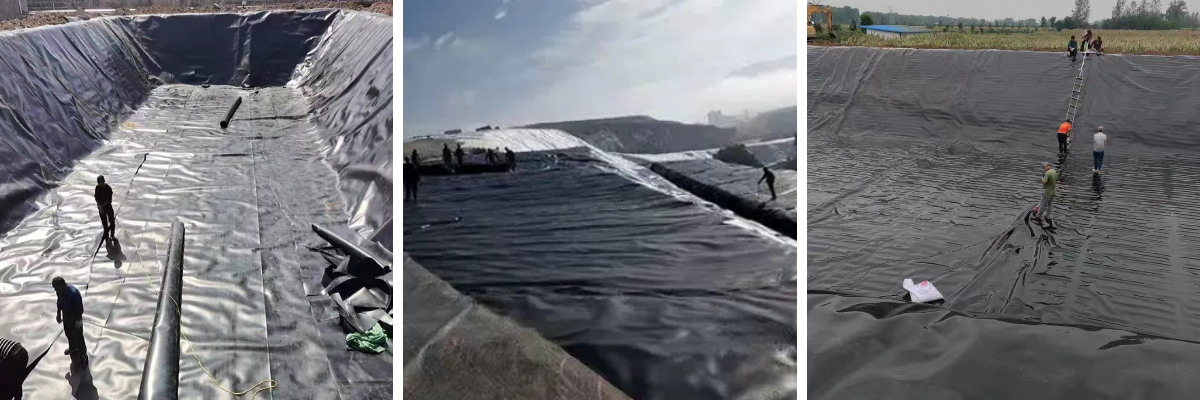

Application scenario

1. Leachate prevention in tailings ponds: Prevent the infiltration of harmful components of tailings to protect the groundwater and soil environment.

2. Landfill sites: As the main waterproof layer, prevent leachate from polluting the surrounding ecology.

3. Hydraulic engineering: Waterproofing at the bottom of reservoirs and channels to reduce water leakage losses.

4. Agricultural fields: Waterproofing of water storage tanks and biogas tanks, or used for isolation and improvement of saline-alkali land.

5. Industrial wastewater treatment: Waterproofing of chemical tanks and wastewater regulating tanks to resist erosion by corrosive liquids. Its high toughness and waterproof property meet the long-term protection requirements in various scenarios.