1.5mm Geomembrane HDPE Liner - Bulk Cloned

1. Superb water-proofing performance: The 1.5mm thick HDPE material has a tightly structured molecular structure, effectively preventing liquid and gas leakage.

2. Excellent durability: It possesses anti-ultraviolet and anti-aging properties, with a service life exceeding 50 years in natural environment.

3. High mechanical strength: The tensile strength is ≥ 28 MPa, the puncture resistance is ≥ 300 N, and it can withstand construction compaction and soil pressure.

4. Easy installation: It maintains good flexibility and can be quickly connected through hot welding, with the weld strength reaching over 90% of the base material.

5. High cost-effectiveness: It balances long-term durability with the initial procurement cost, resulting in a low overall usage cost.

1.5mm HDPE Geomembrane HDPE Liner: A Comprehensive Guide

Chapter 1: Introduction to 1.5mm HDPE Geomembrane

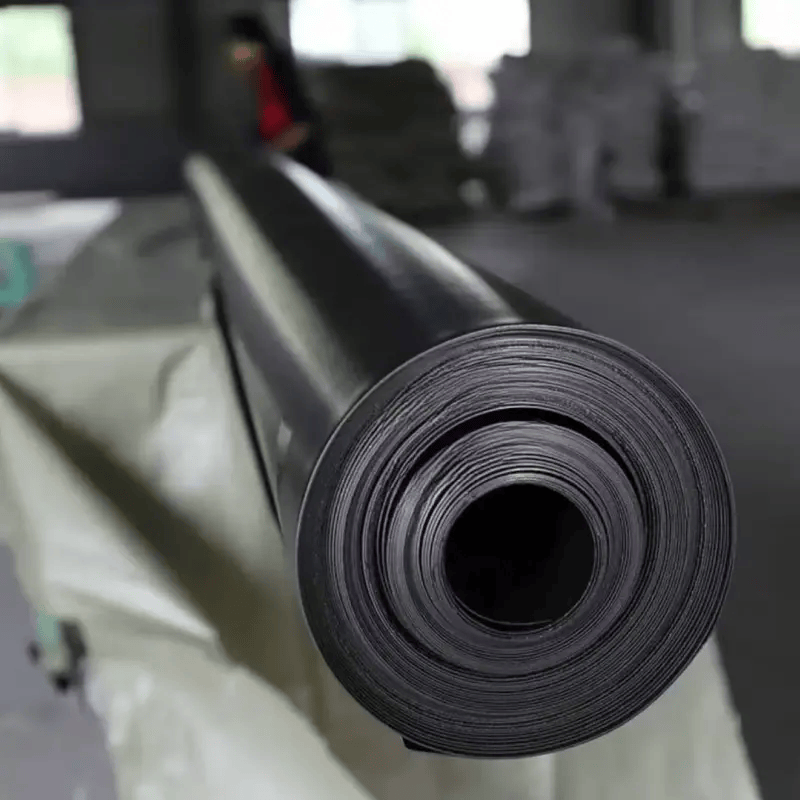

1.5mm HDPE (High-Density Polyethylene) geomembrane is a flexible, durable synthetic liner widely used in environmental, civil engineering, and industrial projects. Made from high-purity HDPE resin, it features excellent impermeability, chemical resistance, and mechanical strength. With a thickness of 1.5mm, it balances flexibility for easy installation and durability for long-term service (typically 50+ years), suitable for landfill liners, pond liners, and wastewater treatment facilities.

Chapter 2: Physical Properties of 1.5mm HDPE Geomembrane

1.5mm HDPE geomembrane boasts outstanding physical performance, including high tensile strength, puncture resistance, and flexibility, ensuring stable performance in various construction environments.

| Physical Property Index | Standard Value |

| Tensile Strength (MD/TD) | ≥28/26 MPa |

| Elongation at Break (MD/TD) | ≥700/650% |

| Puncture Resistance | ≥300 N |

| Tear Resistance (MD/TD) | ≥150/140 N |

| Thickness Tolerance | ±0.1mm |

Chapter 3: Chemical Properties of 1.5mm HDPE Geomembrane

1.5mm HDPE geomembrane exhibits strong resistance to most acids, alkalis, salts, and organic solvents, maintaining structural integrity in harsh chemical environments.

Chemical Property Index | Resistance Level | Test Condition |

| Concentrated Sulfuric Acid (98%) | Excellent | 25℃, 30 days, no degradation |

| Sodium Hydroxide (50%) | Excellent | 25℃, 30 days, no cracking |

| Sodium Chloride (20%) | Excellent | 25℃, 30 days, no weight loss |

| Gasoline (Regular) | Good | 25℃, 14 days, minimal swelling |

| Wastewater (Municipal) | Excellent | 25℃, 90 days, no permeability increase |

Chapter 4: Target Markets for 1.5mm HDPE Geomembrane

1.United States: A top market due to strict environmental regulations (e.g., EPA standards) for landfills, mining, and wastewater treatment; high demand in infrastructure upgrades.

2.China: Driven by large-scale civil engineering projects (e.g., water conservancy, waste management) and government environmental protection initiatives.

3.Germany: Leads in European demand, with applications in renewable energy (biogas plants) and industrial waste treatment, supported by strict sustainability laws.

4.India: Rapidly growing market, fueled by urbanization, need for clean water storage (ponds), and landfill expansion in major cities like Delhi and Mumbai.

Chapter 5: Influencing Factors of 1.5mm HDPE Geomembrane Performance

1.Temperature: Extreme high (>60℃) or low (<-40℃) temperatures can reduce flexibility and tensile strength; avoid installation in extreme weather.

2.Subgrade Condition: Uneven or sharp subgrades (e.g., rocks, debris) increase puncture risk; require smooth, compacted subgrades.

3.Chemical Exposure: Long-term contact with strong oxidants (e.g., concentrated nitric acid) may degrade the membrane; select suitable grades for specific chemicals.

4.UV Radiation: Prolonged outdoor exposure without protection causes aging; use UV-stabilized HDPE or cover with soil/geotextiles.

5.Installation Quality: Poor welding (e.g., incomplete fusion) leads to leakage; require certified installers and strict quality checks.

Chapter 6: Installation Steps for 1.5mm HDPE Geomembrane

1.Subgrade Preparation: Clear the site of debris, rocks, and vegetation; compact the soil to ensure a smooth, stable base (slope ≤1:3 for safety).

2.Membrane Unfolding: Unroll the 1.5mm HDPE geomembrane on the subgrade, aligning edges with minimal overlap (typically 10-15cm); avoid stretching to prevent stress.

3.Welding: Use hot wedge welding machines for seam joining; set temperature (280-320℃) and speed (1.5-2m/min) per manufacturer guidelines; perform test welds first.

4.Seam Inspection: Conduct air pressure tests (200kPa, hold for 30s) and vacuum tests on all welds; repair leaks immediately with patch welding.

5.Anchoring: Secure the membrane edges to concrete curbs or anchor trenches (depth ≥30cm) using bolts or soil backfilling; ensure no gaps at anchors.

6.Final Check: Inspect the entire liner for punctures, wrinkles, or unqualified welds; cover with protective geotextiles or soil (if required) to prevent damage during subsequent construction.

Chapter 7: Haoyang Environment Company Introduction & Advantages

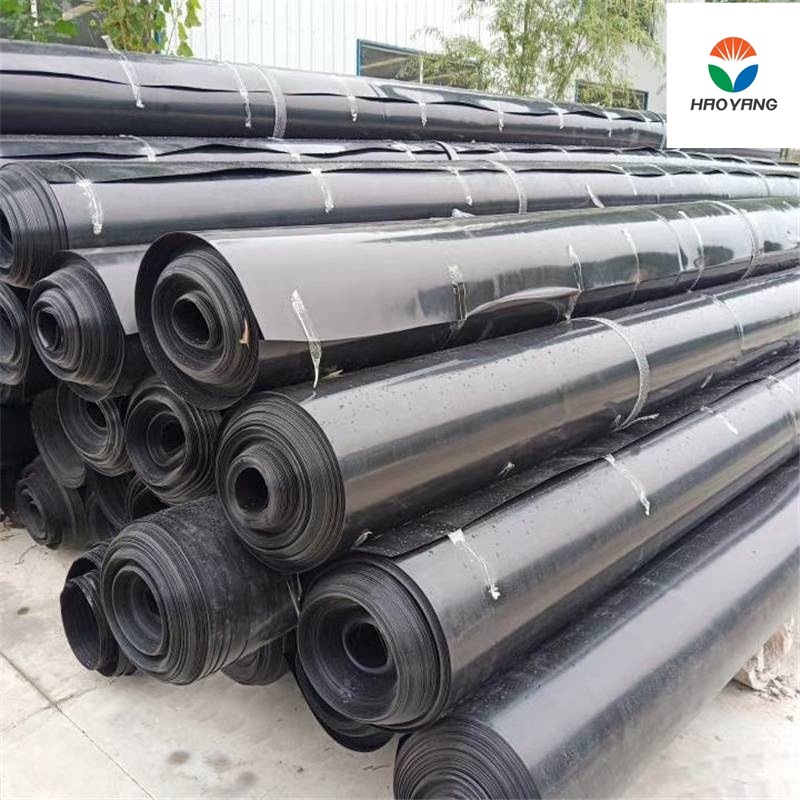

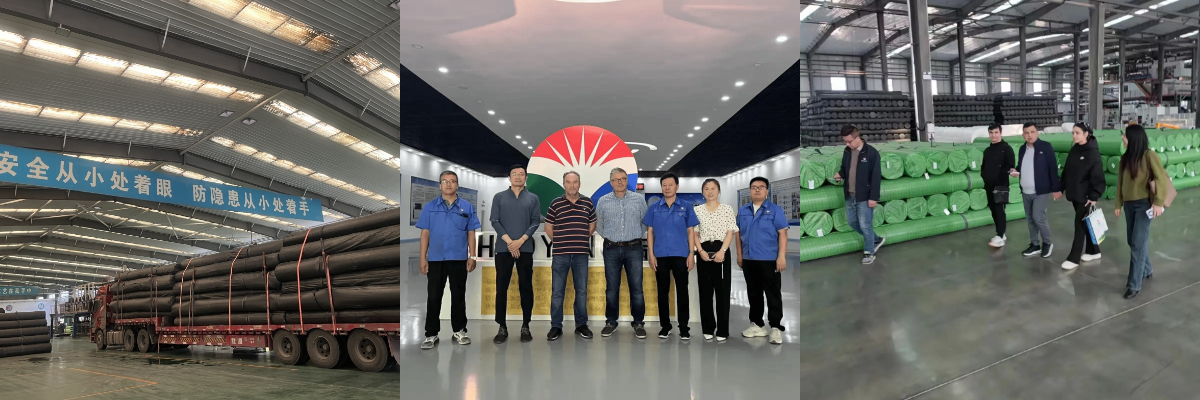

Haoyang Environment is a leading manufacturer and supplier of HDPE geomembranes, with 17+ years of experience in environmental protection materials. Based in China, it serves global clients with ISO 9001-certified products and customized solutions for landfills, water projects, and mining.

1.Quality Assurance: Uses 100% virgin HDPE resin; conducts 10+ quality tests (tensile, permeability) before delivery.

2.Production Capacity: 5 production lines with annual output of 20 million square meters; ensures timely delivery for large projects.

3..Technical Support: Offers on-site installation guidance and seam testing by certified engineers.

4..Global Reach: Exports to 80+ countries; complies with international standards (ASTM, EN, GB).

5.Sustainability: Develops eco-friendly HDPE materials; reduces carbon emissions in production by 12% annually.

Chapter 8: Limitations & Future Trends of 1.5mm HDPE Geomembrane

Limitations

1.5mm HDPE geomembrane has lower flexibility than thinner liners (e.g., 1.0mm), making it harder to install on complex slopes; it is also vulnerable to oxidation in strong UV environments without protection. Additionally, its high density increases transportation costs compared to lightweight alternatives.

Future Trends

The market will see the development of UV-resistant 1.5mm HDPE geomembranes with longer outdoor service life. Integration of recycled HDPE (up to 30% recycled content) will enhance sustainability. Smart liners with embedded sensors for leakage monitoring will become mainstream, improving project safety. Moreover, customized designs for extreme environments (e.g., high-temperature resistant grades for desert areas) will expand application scope.