Smooth HDPE Geomembrane Liner

1. Strong adaptability: The surface is smooth and has good flexibility, which can fit various terrains and be applicable to diverse engineering scenarios such as reservoirs and landfills.

2. Ultra-long durability: It has strong chemical stability, is resistant to acids, alkalis, and organic solvent corrosion, and has excellent physical properties.

3. High environmental friendliness: It is made from food-grade HDPE raw materials, without the release of toxic or harmful substances, and complies with global environmental protection engineering standards.

4. High cost-effectiveness: The raw material utilization rate is high, and its lightweight feature reduces transportation costs, resulting in significant overall cost advantages.

5. Easy construction: It is lightweight (density 0.94-0.96g/cm³), easy to cut, and can be quickly connected through hot wedge welding, shortening the project cycle.

Ⅰ. Brief Introduction to Smooth HDPE Geomembrane

Smooth HDPE Geomembrane Liner is a flexible impermeable material made from high-density polyethylene. It features a smooth surface, strong tensile strength, and excellent waterproof performance. Widely used in environmental protection, water conservancy, and construction, it prevents seepage of liquids and gases, safeguards soil and groundwater, and has a long service life, making it a key material in many engineering projects.

Ⅱ. Chemical Properties of Smooth HDPE Geomembrane

Smooth HDPE Geomembrane has stable chemical properties, resisting most acids, alkalis, organic solvents, and biological erosion, ensuring reliable use in harsh environments.

| Chemical Property Index | Standard Requirement | Typical Value |

| Resistance to Sulfuric Acid (50%, 25℃, 7d) | No cracking, no deformation | No cracking, no deformation |

| Resistance to Sodium Hydroxide (40%, 25℃, 7d) | Mass change ≤ ±2% | Mass change +0.8% |

| Resistance to Gasoline (25℃, 7d) | Volume change ≤ ±3% | Volume change +1.2% |

| Resistance to Diesel Oil (25℃, 7d) | No obvious discoloration | No obvious discoloration |

| Resistance to Salt Water (3.5%, 25℃, 30d) | Tensile strength retention ≥ 90% | Tensile strength retention 95% |

| Resistance to Acetic Acid (10%, 25℃, 7d) | Elongation retention ≥ 85% | Elongation retention 92% |

| Resistance to Ethanol (95%, 25℃, 7d) | No surface damage | No surface damage |

| Resistance to Formaldehyde (37%, 25℃, 7d) | Mass change ≤ ±1.5% | Mass change +0.5% |

Ⅲ. Physical Properties of Smooth HDPE Geomembrane

Smooth HDPE Geomembrane has excellent physical properties, with high tensile strength, good elongation, and strong puncture resistance, adapting to various engineering needs.

| Physical Property Index | Standard Requirement | Typical Value |

| Tensile Strength (MPa) | ≥ 18 | 22 |

| Elongation at Break (%) | ≥ 400 | 450 |

| Puncture Resistance (N) | ≥ 300 | 360 |

| Thickness (mm) | 0.5-3.0 (optional) | 1 |

| Thickness Deviation (%) | ± 10 | ± 7 |

| Tear Strength (kN/m) | ≥ 50 | 65 |

| Impact Resistance (20℃, kg·cm) | ≥ 20 | 25 |

| Density (g/cm³) | 0.94-0.96 | 0.95 |

Ⅳ. Target Market Segmentation of Smooth HDPE Geomembrane

The global market for smooth HDPE geomembrane is concentrated in six major countries.

1.The United States has high demand for waste landfill and water treatment projects, with strict environmental standards driving usage.

2.China, amid infrastructure development, uses it in reservoirs, canals, and expressway anti-seepage projects.

3.India relies on it for agricultural irrigation and industrial wastewater treatment.

4.Germany applies it in ecological restoration and waste disposal.

5.Brazil uses it in dam construction and mining tailings treatment.

6.Australia needs it for water storage in arid areas, such as reservoirs and ponds.

Ⅴ. Factors Affecting the Price of Smooth HDPE Geomembrane

1.Raw material cost: HDPE resin price fluctuations directly impact production costs, with higher resin prices raising geomembrane prices.

2.Product specifications: Thicker or customized geomembranes require more materials and complex processes, increasing prices.

3.Production scale: Large-scale production reduces unit costs, so big manufacturers offer more competitive prices.

4.Transportation cost: Long-distance or remote-area transportation adds expenses, included in the final price.

5.Market supply-demand: High demand with limited supply pushes prices up; oversupply leads to price drops.

Ⅵ. Application Scenarios of Smooth HDPE Geomembrane

1.Waste landfills: Prevent leachate seepage, protecting soil and groundwater from pollution.

2.Water conservancy projects: Used in reservoirs, canals, and dams to enhance impermeability and improve water storage.

3.Water treatment plants: Line sedimentation tanks and filter pools to avoid sewage leakage.

4.Agricultural irrigation: Line irrigation canals to reduce water seepage loss and save water resources.

5.Mining industry: Line tailings ponds to prevent heavy metal wastewater from contaminating the environment.

6.Ecological restoration: Used in wetland reconstruction and riverbank protection to maintain ecological balance.

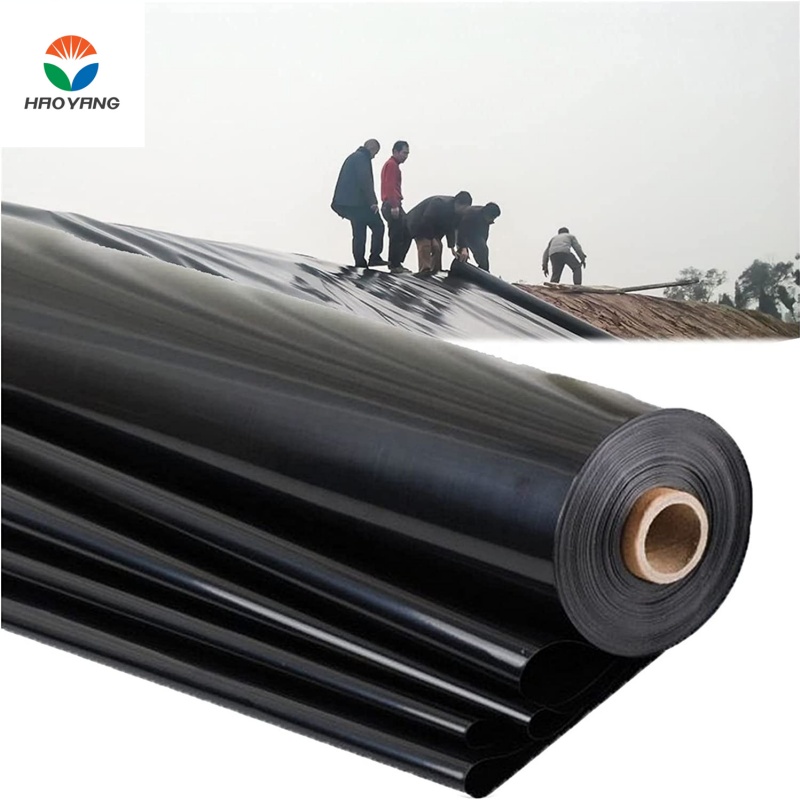

Ⅶ. On-Site Installation Steps of Smooth HDPE Geomembrane

1.Site preparation: Clear debris, level the ground, and compact the soil to ensure a flat, solid foundation without sharp objects.

2.Geomembrane unrolling: Unroll the geomembrane along the project direction, avoid wrinkles, and leave a 10-15cm margin for splicing.

3.Splicing operation: Use hot wedge welding, ensure a welding width of 10cm, and test the weld for air tightness to avoid leakage.

4.Laying and fixing: Lay the spliced geomembrane on the foundation, fix edges with anchor trenches or weights to prevent displacement.

5.Inspection and repair: Check for holes or poor splicing; repair damaged areas with the same material using welding.

6.Backfilling protection: Backfill with soil or sand in layers, compact gently to avoid damaging the geomembrane.

Ⅷ. Introduction to Haoyang Environment and Reasons for Choosing Its Geomembrane

Haoyang Environment is a professional enterprise integrating R&D, production, and sales of environmental protection materials, with advanced HDPE geomembrane production lines and a professional technical team. It has passed ISO9001 quality certification and has rich experience in engineering applications. Choosing Haoyang Environment: its geomembrane uses high-quality HDPE resin, ensuring stable performance; it has strict quality inspection, guaranteeing product qualification; it provides customized solutions and on-site installation guidance, solving customer problems efficiently, winning market recognition.

Ⅸ. Shortcomings and Development Trends of Smooth HDPE Geomembrane

Currently, smooth HDPE geomembrane has shortcomings: poor friction on smooth surfaces, easy slippage on steep slopes; weak low-temperature resistance, prone to brittleness in cold areas. Development trends: modify the surface to increase friction; optimize formulas to enhance low-temperature resistance; develop higher impermeability products to meet strict environmental standards; integrate intelligent monitoring technology to realize real-time monitoring of geomembrane integrity, improving engineering safety and reliability.