How To Choose The Right HDPE Geomembrane For Your Project

1. Excellent Waterproofing Performance

Provides superior impermeability to prevent leakage and protect water resources.

2. High Chemical and UV Resistance

Resists corrosion, chemical erosion, and UV degradation for long-term durability.

3. Wide Temperature Adaptability

Performs well under extreme hot and cold environmental conditions.

4. Easy Installation and Welding

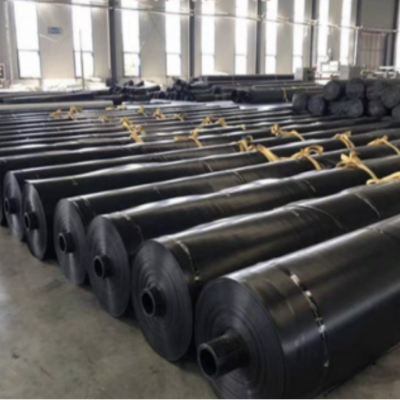

Lightweight material with flexible welding options for fast and secure construction.

5. Long Service Life and Low Maintenance

Made from 100% virgin HDPE for enhanced strength, ensuring over 20 years of reliable use.

Selecting the right HDPE geomembrane is one of the most important decisions in any waterproofing or containment project. Whether it is for a landfill, fish pond, reservoir, mining pit, or wastewater treatment system, the quality and specifications of the geomembrane directly affect the safety, performance, and lifespan of the entire project. Understanding how to choose the right type of geomembrane can help you achieve better results while reducing long-term maintenance costs.

What is an HDPE Geomembrane?

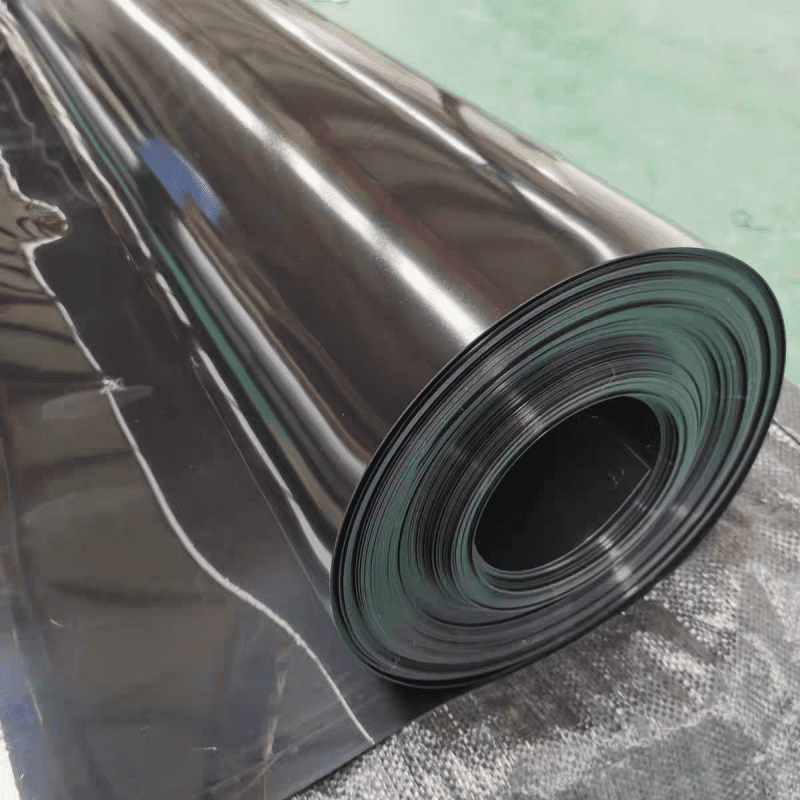

HDPE (High-Density Polyethylene) geomembrane is a waterproofing liner made from premium polyethylene resin. It is known for its excellent chemical resistance, strong mechanical properties, and high durability under extreme environmental conditions. Compared with traditional materials such as concrete or clay, HDPE geomembrane offers superior impermeability and flexibility, making it the preferred choice for modern environmental and engineering applications.

1. Consider the Application Requirements

The first step in choosing the right geomembrane is to clearly understand the application scenario.

Different projects have different performance demands:

Aquaculture ponds and irrigation tanks require safe, non-toxic liners that prevent water leakage and protect aquatic life.

Landfills and mining sites demand heavy-duty liners that resist chemical attack and puncture from sharp waste or stones.

Water reservoirs and canals need UV-stabilized materials that can withstand long exposure to sunlight.

Industrial wastewater treatment systems call for geomembranes with strong chemical and temperature resistance.

Understanding your specific project conditions will help you select the right thickness, texture, and formulation of the HDPE geomembrane.

2. Choose the Appropriate Thickness

Thickness is one of the key parameters determining a geomembrane’s strength and durability. HDPE liners are usually available in thicknesses ranging from 0.5mm to 3.0mm, depending on the application.

For small fish ponds or decorative lakes, a 0.75mm–1.0mm liner is often sufficient.

For irrigation canals or reservoirs, 1.0mm–1.5mm is commonly used.

For landfills or mining containment, thicker geomembranes (2.0mm or more) are recommended for maximum protection.

Thicker materials provide better puncture resistance and a longer service life, but they may also require more careful handling during installation. Always balance performance needs with cost efficiency.

3. Look for 100% Virgin HDPE Material

The quality of raw materials plays a decisive role in the performance of the geomembrane. High-quality liners are made from 100% virgin HDPE resin, which ensures consistent mechanical strength, flexibility, and resistance to environmental stress cracking.

Some low-cost products may contain recycled materials, which can reduce tensile strength and shorten the service life of the liner. For critical projects like landfills, mining, or drinking water storage, always insist on virgin raw materials certified by ISO and ASTM standards.

4. Check for UV and Chemical Resistance

Geomembranes used outdoors must resist UV radiation to prevent aging and cracking. A good HDPE geomembrane contains anti-UV stabilizers and antioxidants, enabling it to perform reliably under long-term sunlight exposure.

If the project involves contact with acidic or alkaline substances, such as industrial wastewater or mining tailings, chemical resistance becomes equally important. HDPE is naturally resistant to a wide range of chemicals, but it is still essential to confirm that the liner meets the required chemical compatibility standards.

5. Evaluate Surface Texture and Flexibility

HDPE geomembranes come in smooth and textured surfaces.

Smooth geomembranes are used when impermeability and ease of cleaning are most important.

Textured geomembranes provide better friction and stability on steep slopes or vertical surfaces, helping to prevent slippage during construction.

Flexibility also matters. A good-quality geomembrane should remain pliable even in cold weather, ensuring easier installation and reliable welding.

6. Pay Attention to Installation and Welding Quality

Even the best geomembrane will not perform well if it is poorly installed. Choose a supplier or contractor with professional experience in geomembrane installation.

HDPE liners are typically welded using hot wedge welding or extrusion welding, which ensures a seamless and watertight joint. Proper welding not only prevents leakage but also extends the service life of the liner. Always request on-site testing of weld seams, such as vacuum tests or air pressure tests, to confirm the integrity of the joints.

7. Compare Technical Certifications and Test Reports

Reliable geomembrane manufacturers will provide complete technical data sheets (TDS), quality certifications, and test reports from recognized laboratories. These documents specify important mechanical properties such as tensile strength, elongation, tear resistance, puncture resistance, and permeability coefficient.

Make sure the geomembrane meets relevant international standards, such as GM13 (ASTM) or GB/T 17643-2011 (China). Choosing certified materials guarantees that you are investing in a product that has been rigorously tested for quality and safety.

8. Consider Environmental Impact and Sustainability

As global awareness of environmental protection grows, choosing eco-friendly materials has become increasingly important. HDPE geomembrane is non-toxic, recyclable, and safe for soil and water environments, making it suitable for aquaculture, agriculture, and drinking water applications.

Furthermore, its long lifespan—often exceeding 20 years under proper maintenance—reduces replacement frequency and waste, making it both an economically and environmentally sustainable choice.

Advantages of HDPE Geomembrane

Excellent Waterproofing Performance – Provides superior impermeability and long-term leak protection.

High Chemical and UV Resistance – Withstands harsh environments without degradation.

Wide Temperature Adaptability – Performs well under both hot and cold climates.

Easy Installation and Welding – Lightweight, flexible, and suitable for large-scale projects.

Long Service Life and Low Maintenance – Durable for decades with minimal upkeep.

Environmentally Friendly Material – Non-toxic and safe for aquaculture and agriculture.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Choosing the right HDPE geomembrane is not only about product selection—it’s about ensuring the success and longevity of your entire project. By carefully considering application needs, thickness, raw material quality, UV and chemical resistance, and installation standards, you can achieve a waterproofing system that performs reliably for decades.

At Haoyang Environmental Co., Ltd., we specialize in manufacturing and supplying high-quality HDPE geomembranes made from 100% virgin materials. Our products are widely used in aquaculture, agriculture, landfill, reservoir, and industrial projects worldwide, trusted for their durability, performance, and safety.

If you are planning a waterproofing or containment project, our technical team can help you select the right geomembrane specifications and provide professional installation guidance to ensure long-term success.