2mm PVC Geomembrane

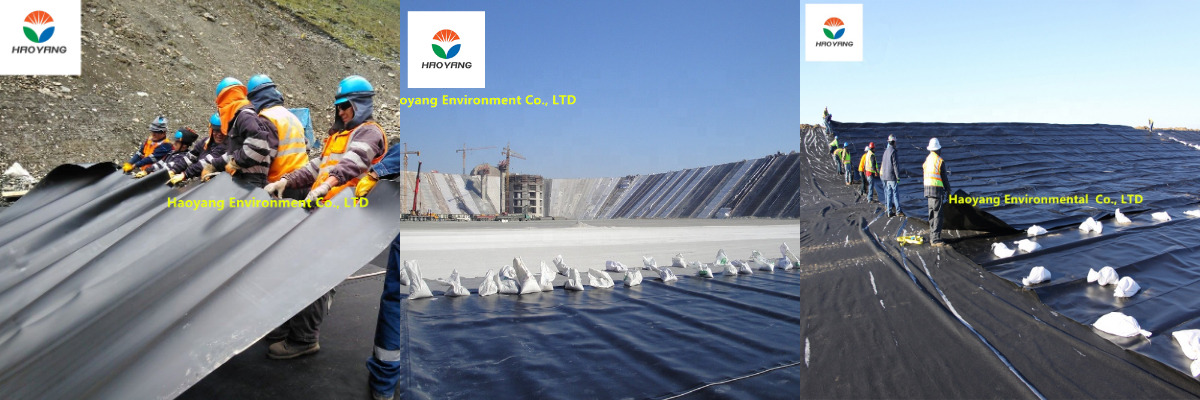

Versatile Applications

Used globally in landfills, aquaculture ponds, agricultural reservoirs, and chemical containment systems.

Recyclable & Sustainable

Post-industrial scrap can be repurposed, aligning with circular economy principles in sustainable infrastructure projects.

2mm PVC Geomembrane: Technical Performance, Industrial Applications, and Sustainability

Polyvinyl chloride (PVC) geomembranes are widely recognized for their robustness in demanding environmental and industrial applications. The 2mm PVC geomembrane, a thicker variant compared to its 1mm counterpart, offers enhanced mechanical strength, puncture resistance, and longevity, making it a preferred choice for projects requiring superior durability. This article delves into the technical attributes, sector-specific applications, and ecological considerations of 2mm PVC geomembranes, supported by empirical data and industry benchmarks.

1. Technical Characteristics of 2mm PVC Geomembrane

The superior performance of 2mm PVC geomembranes stems from their material composition and manufacturing precision. Below is a detailed analysis of their physical, mechanical, and environmental properties.

1.1 Physical Properties

| Parameter | Specification | Test Standard |

Thickness (nominal) | 2.0 mm ± 3% | ASTM D5199 |

Mass per Unit Area | 2,800–3,200 g/m² | ASTM D792 |

Density | 1.4–1.6 g/cm³ | ASTM D792 |

Water Absorption | <0.1% by volume | ASTM D570 |

Oxygen Index | ≥28% | ASTM D2863 |

1.2 Mechanical Performance

| Parameter | Typical Range | Test Method |

Tensile Strength (MD/TD) | 40–50 MPa | ASTM D6693 |

Elongation at Break (MD/TD) | 300–400% | ASTM D6693 |

Puncture Resistance | >400 N | ASTM D4833 |

Tear Resistance (Trapezoid) | 150–200 N | ASTM D5587 |

Shear Strength (Dry) | 50–70 kPa | ASTM D5321 |

1.3 Environmental Resistance

| Parameter | Performance Metric | Test Conditions |

UV Exposure (ASTM G154) | No cracking at 8,000 h | 0.89 W/m²@340nm, 65°C |

Hydrolytic Stability | Passes 120°C, 7 days | ASTM D573 |

Low-Temperature Flexibility | -45°C (no cracks) | ASTM D746 |

Oxidative Induction Time | >100 min | ASTM D5721 |

1.4 Chemical Compatibility

| Chemical Agent | Resistance Rating | Exposure Duration |

Sulfuric Acid (30%) | Excellent | 30 days, 25°C |

Sodium Hypochlorite (10%) | Good | 14 days, 25°C |

Diesel Fuel | Fair | 7 days, 25°C |

Methanol | Limited | 3 days, 25°C |

2. Key Application Sectors

The enhanced thickness of 2mm PVC geomembranes extends their utility to high-stress environments. Primary applications include:

2.1 Mining and Mineral Processing

Tailings Dams: Withstands abrasive slurries and dynamic loads.

Heap Leach Pads: Resists chemical degradation from cyanide solutions.

Process Water Ponds: Contains acidic runoff in ore processing.

2.2 Heavy Industrial Containment

Chemical Storage Basins: Secondary containment for aggressive substances.

Oil and Gas Infrastructure: Liners for fracking fluid pits.

Power Plants: Fly ash ponds and desulfurization systems.

2.3 Civil Engineering

Canal and Reservoir Liners: Prevents seepage in high-pressure water bodies.

Landfill Caps: Acts as a protective barrier over waste masses.

Tunnel Waterproofing: Multi-layer systems for underground structures.

2.4 Aquaculture and Agriculture

Shrimp Ponds: Withstands saltwater corrosion and UV exposure.

Irrigation Reservoirs: Minimizes water loss in arid regions.

3. Performance Comparison: 2mm vs. 1mm PVC Geomembranes

The additional thickness of 2mm membranes provides measurable advantages in critical parameters:

| Metric | 1mm Membrane | 2mm Membrane | Improvement (%) |

Puncture Resistance | 200–250 N | 400–450 N | +100 |

Tensile Strength | 25–35 MPa | 40–50 MPa | +67 |

UV Resistance Lifespan | 20–25 years | 30–35 years | +40 |

Abrasion Resistance (Taber) | 50–80 mg loss | 20–40 mg loss | -50 |

4. Installation Guidelines

Proper installation is critical to harness the full potential of 2mm PVC geomembranes:

4.1 Subgrade Preparation

Compaction: Achieve ≥98% Modified Proctor Density for soil substrates.

Slope Stability: Maintain ≤3:1 gradients to minimize shear stress.

Protection Layer: Install geotextile underlayment (≥200 g/m²) to prevent puncture.

4.2 Welding Protocols

| Parameter | Optimal Range |

Welding Temperature | 500–600°C |

Welding Speed | 1.0–2.0 m/min |

Seam Overlap | 100–150 mm |

Air Channel Test | ≤25 mm Hg pressure drop |

4.3 Quality Assurance

Destructive Testing: Peel and shear tests on 1% of welded seams.

Non-Destructive Testing: Electro-magnetic induction (EMI) scans for voids.

Visual Inspection: Check for fishmouths, wrinkles, and foreign debris.

5. Real-World Implementation Example

5.1 Case Study: Central European Chemical Park

A 2mm PVC geomembrane was deployed as the primary liner for a 50-hectare chemical storage facility in Germany:

Design Life: 40 years (exceeding regulatory requirements).

Performance: Zero leakage detected via electrical leak location surveys after 8 years.

Cost-Benefit: 15% higher initial cost vs. 1mm membrane, but 40% lower lifecycle maintenance.

5.2 Case Study: Australian Gold Mine Tailings Facility

In a harsh Outback environment:

Application: Tailings dam lining (2.5mm composite system with geotextile).

Challenges: Extreme temperature fluctuations (-5°C to 45°C), high abrasion.

Outcome: No membrane degradation after 10 years; puncture repairs <0.01/ha.

6. Environmental and Sustainability Considerations

Modern 2mm PVC geomembranes incorporate eco-conscious features:

Recyclability: Post-industrial scrap recycled into drainage cells (up to 50% content).

Additive Innovation: Bio-based plasticizers reduce fossil fuel dependence.

Carbon Footprint: Thicker membranes offer lower replacement frequency, reducing long-term emissions.

7. Market Trends and Innovations

The 2mm PVC geomembrane sector is evolving with:

Nano-Coatings: Titanium dioxide layers for self-cleaning properties.

Smart Sensors: Embedded fibers for real-time leak detection.

Hybrid Systems: Combination with HDPE or bitumen for extreme conditions.

8. Conclusion

The 2mm PVC geomembrane establishes itself as a high-performance solution for industries demanding reliability under extreme conditions. Its enhanced mechanical properties, coupled with advancements in material science, position it as a sustainable choice for infrastructure longevity. As regulatory standards tighten and environmental risks grow, the 2mm variant’s balance of durability and adaptability ensures its continued relevance in global engineering projects.