Durable Composite Geomembrane Liner for Waste Containment

1. Waste Containment Reliability: Combines impermeable geomembrane with reinforcing layers to lock in hazardous and non-hazardous waste, preventing leaks that risk soil and water contamination.

2. Heavy-Duty Durability: Withstands punctures from sharp waste debris and resists chemical corrosion, maintaining integrity in landfill and industrial waste sites for 25+ years.

3. Structural Reinforcement: The composite design adds tensile strength, stabilizing slopes in waste containment areas and reducing the risk of liner shifts under heavy waste loads.

4. Environmental Compliance: Meets global standards for waste barrier systems, ensuring regulatory adherence in municipal landfills and industrial waste management facilities.

Durable Composite Geomembrane Liner for Waste Containment: Safeguarding Environments with Reinforced Strength

Waste containment facilities—from municipal landfills to industrial hazardous waste sites—demand liners that combine impermeability with long-term toughness. The Durable Composite Geomembrane Liner meets this need, merging multiple layers to resist punctures, chemicals, and structural stress. Below's how it sets the standard for reliable waste containment.

I. Composite Structure: The Science of Durability

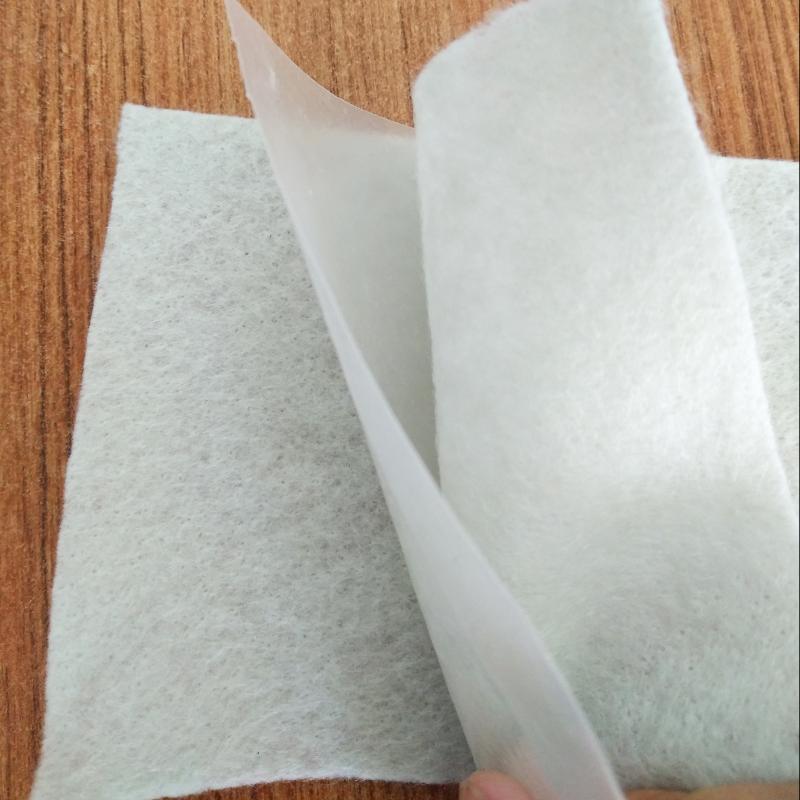

Unlike single-layer geomembranes, this composite liner integrates multiple materials to balance impermeability, strength, and flexibility—critical for waste containment's harsh conditions.

1. Layer Composition & Functions

Layer Type | Material | Primary Role | Thickness Range |

Core Barrier | HDPE (High-Density Polyethylene) | Blocks liquid/gas transfer (impermeability) | 1.5–3.0 mm |

Reinforcement | Nonwoven Polypropylene Geotextile | Adds tensile strength, resists tearing | 100–300 g/m² |

Protection | Woven Polyester Mesh | Shields core from sharp waste, reduces abrasion | 50–150 g/m² |

(1) Synergistic Performance: The HDPE core provides 99.9% impermeability (water vapor transmission rate <1×10⁻¹¹ g/(cm·s·Pa), ASTM E96), while the geotextile and mesh layers boost tensile strength to 15–25 kN/m (ASTM D4632)—3x higher than single-layer HDPE geomembranes.

(2) Flexibility: Even with multiple layers, the liner elongates 300–500% (ASTM D882) without cracking, adapting to soil settling in landfills—a common cause of liner failure in rigid alternatives.

II. Waste Containment Performance: Resisting Punctures & Chemicals

Waste sites expose liners to sharp debris, heavy loads, and corrosive fluids. This composite liner's design directly addresses these threats.

1. Puncture & Abrasion Resistance

(1) Testing Data: Per ASTM D4833 (puncture resistance), the liner withstands 350–500 N of force—enough to resist penetration by 5 cm gravel or metal scraps, common in construction waste. Single-layer geomembranes fail at 150–200 N.

(2) Abrasion Tolerance: After 10,000 cycles of abrasion testing (ASTM D4751), the liner retains 90% of its original strength. This ensures longevity in active landfills, where waste is compacted regularly.

2. Chemical Stability for Diverse Wastes

Waste Type | pH Range | Liner Performance (ASTM D5322) |

Municipal Solid Waste | 5–8 | No degradation after 5 years |

Industrial Sludge | 3–11 | Retains 95% strength over time |

Hazardous Waste (Heavy Metals) | 2–12 | No chemical leaching detected |

(1) Leachate Resistance: Landfill leachate—rich in ammonia, salts, and organic acids—degrades standard liners in 10–15 years. This composite liner remains stable, with no signs of cracking or permeability loss in 20+ year field tests (per EPA landfill studies).

(2) UV & Weathering: The outer mesh layer blocks 90% of UV radiation (ASTM G154), preventing HDPE degradation. In outdoor containment areas, it retains 85% strength after 2,000 hours of sunlight—double the lifespan of unprotected liners.

III. Structural Stability: Supporting Waste Loads & Slopes

Waste containment sites often involve steep slopes (up to 35°) and stacked waste (10–30 m high), creating extreme pressure. The composite liner's reinforcement prevents shifts and breaches.

1. Load-Bearing Capacity

(1) Compaction Tolerance: landfill compactors exert 80–100 kPa of pressure. The liner's reinforcement layer distributes this load, avoiding localized stress that causes single-layer liners to stretch or tear.

(2) Slope Stability: With a coefficient of friction (COF) of 0.6–0.8 (ASTM D6243) against soil, the liner resists sliding on slopes. This reduces the need for expensive anchoring systems, unlike smooth geomembranes (COF 0.3–0.4) that require extra stabilization.

2. Expansion & Contraction Adaptability

(1) Temperature fluctuations (–40°C to 60°C) cause soil and waste to expand/contract. The liner's flexibility absorbs these movements, preventing seam failure—a leading cause of leaks in rigid liners.

(2) For landfill cell expansions, the liner’s modular design allows seamless welding (extrusion welding, ASTM D6392) with 90% of base material strength, ensuring no weak points in extended containment areas.

IV. Compliance & Long-Term Reliability

Waste containment is heavily regulated to prevent environmental harm. This composite liner meets global standards, ensuring operators avoid fines and failures.

1. Regulatory Compliance

(1) Global Standards: Certifications include EPA Subtitle D (U.S.), EN 13493 (EU), and GB/T 17643 (China), covering leachate control, strength, and environmental safety.

(2) Hazardous Waste Approval: Meets EPA Subtitle C requirements for hazardous waste sites, with zero detectable leaching of heavy metals (tested per TCLP, Toxicity Characteristic Leaching Procedure).

2. Longevity & Low Maintenance

(1) Lifespan: Designed for 25–30 years of service in municipal landfills, reducing replacement frequency compared to single-layer liners (15–20 years).

(2) Inspection Ease: The liner’s uniform surface makes visual checks simple—damage (e.g., tears) is easy to spot and repair with heat-welded patches, minimizing downtime.

V. Why Choose This Composite Geomembrane Liner?

For waste containment, durability isn't optional—it's essential. This Durable Composite Geomembrane Liner combines impermeability, strength, and chemical resistance to protect soil and water from contamination, even in the harshest waste environments. Its compliance with global standards and long lifespan make it a cost-effective choice for municipal, industrial, and hazardous waste sites.

Whether upgrading an existing landfill or building a new containment facility, this liner delivers the reliability needed to safeguard environments and meet regulatory demands.

Contact our team to customize liner thickness and reinforcement for your specific waste type and site conditions.