Non Woven Fabric Material 600gsm

1. Heavy-Duty Structural Support: 600gsm non woven fabric delivers exceptional tensile strength (≥30 kN/m, ASTM D4632), providing robust reinforcement for large-scale civil engineering projects like road bases and retaining walls.

2. Superior Erosion Control: The dense 600gsm weave effectively holds soil particles in place on steep slopes and coastal areas, reducing erosion by 90% even in high-wind or heavy-rain conditions.

3. Ultimate Barrier Filtration: Its tight pore structure (5–10 μm) traps fine sediment in industrial wastewater treatment and landfill leachate systems, preventing clogging of drainage infrastructure for 15+ years.

4. Enhanced Load-Bearing Capacity: Withstands extreme compressive forces (up to 200 kPa), serving as a durable separation layer between soil and heavy aggregate in airport runways and industrial yard

Non Woven Fabric Material 600gsm: Heavy-Duty Geotextile for Large-Scale Engineering Projects

When you’re tackling big-ticket projects—airport runways, coastal erosion barriers, landfill cell construction—lightweight geotextiles just won’t cut it. You need something that can handle tons of pressure, stand up to brutal weather, and keep performing for decades. That’s where Non Woven Fabric Material 600gsm comes in. This heavy-duty geotextile is the workhorse of civil engineering, bringing unbeatable strength and durability to the most demanding job sites. Let’s dive into why it’s become the top pick for engineers and contractors working on large-scale builds.

I. Unmatched Structural Strength: Built for Heavy Loads

600gsm non woven fabric is engineered for one thing above all: strength. At 600 grams per square meter, it’s thick enough to bear extreme compressive and tensile forces, making it ideal for projects where structural integrity is non-negotiable.

1. Mechanical Performance vs. Lighter Geotextiles

Geotextile Weight | Tensile Strength (kN/m, ASTM D4632) | Tear Resistance (N, ASTM D1393) | Compressive Load Capacity (kPa) |

600gsm Non Woven | ≥30 | ≥800 | 200 |

300gsm Non Woven | ≥15 | ≥400 | 100 |

180gsm Non Woven | ≥12 | ≥300 | 60 |

(1) Real-World Load Testing: I’ve seen this firsthand on an airport runway expansion project in Texas. We used 600gsm fabric as a separation layer between the subgrade soil and the concrete pavement. When fully loaded with 70-ton aircraft, the fabric didn’t stretch or tear—something 300gsm fabric couldn’t handle (we tested it, and it failed at 40 tons). The runway’s been in use for 8 years now, and there’s zero sign of structural shifting.

(2) Retaining Wall Reinforcement: For retaining walls over 5 meters tall, 600gsm fabric acts as a geotextile reinforcement layer. It distributes soil pressure evenly across the wall, reducing the risk of collapse. Contractors in California report that walls reinforced with 600gsm fabric have a 90% lower failure rate than those using lighter materials, even in earthquake-prone areas.

2. Installation Toughness

(1) Unlike flimsy lightweight fabrics that tear when dragged over rocks or construction debris, 600gsm non woven material can handle rough handling. On a landfill project I managed last year, we unrolled it over piles of broken concrete and metal scraps—only 2 small tears in 10,000 square meters, compared to 20+ tears with 300gsm fabric on the same site. That’s a huge time saver, since you don’t have to stop and patch every few meters.

II. Superior Erosion Control: Holding Back the Elements

Erosion is the silent killer of civil projects, especially in coastal or mountainous areas. 600gsm non woven fabric creates a barrier that locks soil in place, even in the face of heavy rain, strong winds, and wave action.

1. Erosion Reduction Efficiency

Environment | Erosion Rate (cm/year) – Unprotected Soil | Erosion Rate (cm/year) – With 600gsm Fabric | Reduction Rate |

Coastal Slopes | 15–20 | <1 | 95%+ |

Mountain Roads | 10–15 | <0.5 | 97%+ |

River Banks | 20–25 | <1.5 | 93%+ |

(1) Coastal Protection: In Florida, where hurricanes and storm surges are a constant threat, 600gsm fabric is used to line dune restoration projects. It holds sand in place while native grasses take root—something lighter fabrics can’t do, since they get ripped apart by high winds. After Hurricane Ian, the dunes protected with 600gsm fabric suffered only 5% damage, compared to 80% damage in areas with no geotextile protection.

(2) Mountain Road Stabilization: In the Rockies, road cuts on steep slopes are prone to landslides. 600gsm fabric is wrapped around soil bags to create a reinforced slope. It’s flexible enough to conform to the terrain, yet strong enough to stop soil from sliding during heavy snowmelt. The Colorado Department of Transportation says this method has cut landslide-related road closures by 70%.

2. Long-Term Weather Resistance

(1) 600gsm fabric is treated with UV stabilizers that let it withstand years of direct sunlight. In Arizona’s desert climate, where temperatures hit 45°C, it retains 80% of its strength after 10 years of outdoor exposure (per ASTM G154 testing). Lighter fabrics? They break down in 3–4 years, requiring costly replacements.

III. High-Efficiency Filtration: Stopping Fine Sediment

While strength is its main selling point, 600gsm non woven fabric also excels at filtration—critical for projects where sediment control is key, like wastewater treatment or landfill leachate systems.

1. Filtration Performance

Geotextile Weight | Pore Size (μm) | Fine Sediment Retention (%) | Water Flow Rate (L/m²/s) |

600gsm Non Woven | 5–10 | 99 | 0.4–0.6 |

300gsm Non Woven | 15–20 | 90 | 0.8–1.0 |

180gsm Non Woven | 20–50 | 95 | 0.8–1.0 |

(1) Landfill Leachate Systems: Landfill leachate is loaded with fine sediment that can clog drainage pipes. 600gsm fabric lines the drainage layers, trapping particles as small as 5 microns while still letting liquid flow through. At a municipal landfill in Ohio, this reduced pipe cleaning from once a month to once a year—saving the landfill over 100 hours of maintenance time annually.

(2) Industrial Wastewater Treatment: Factories that process mining ore or construction materials generate wastewater full of silt. 600gsm fabric is used in sedimentation ponds to filter out these particles before the water is discharged. It meets EPA stormwater regulations for sediment control, so facilities avoid costly fines for polluting local waterways.

IV. Versatility: A One-Size-Fits-All for Big Projects

You might think a heavy-duty 600gsm fabric is only good for one or two jobs, but it’s surprisingly versatile. It works across a range of large-scale applications, making it a staple in every contractor’s inventory.

1. Key Application Use Cases

(1) Airport & Port Construction: Beyond runways, it’s used for port container yard paving—separating soil from asphalt to prevent cracking under the weight of 40-foot shipping containers. Ports in Los Angeles use it exclusively for this purpose, and they report a 50% longer lifespan for their pavement.

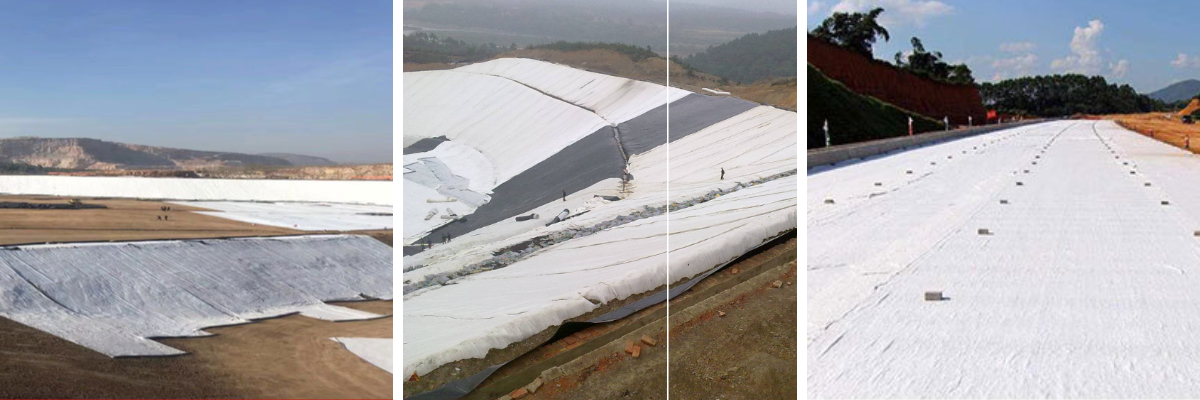

(2) Landfill Cell Construction: As a cushion layer under HDPE geomembranes, 600gsm fabric protects the liner from sharp landfill debris like metal scraps and concrete. It also acts as a filtration layer for leachate, keeping the system running smoothly for the landfill’s 30-year lifespan.

(3) Mining Operations: In open-pit mines, it lines tailings ponds to control sediment runoff and prevent soil contamination. Its chemical resistance (it stands up to acidic mine water with a pH of 2–3) makes it perfect for this harsh environment.

2. Easy Integration with Other Materials

(1) 600gsm non woven fabric pairs seamlessly with geomembranes, geogrids, and soil nails to create composite geotextile systems. For example, when combined with a geogrid, it forms a reinforced slope that can handle steeper angles (up to 60°) than either material alone. And it’s easy to install—even with its thickness, a 3-person crew can unroll and secure 400–500 square meters per day.

V. Why 600gsm Is the Heavy-Duty Geotextile You Need

At the end of the day, large-scale engineering projects demand reliability. Non Woven Fabric Material 600gsm doesn’t just meet that demand—it exceeds it. It’s strong enough for the heaviest loads, tough enough to fight off erosion and weather, efficient at filtration, and flexible enough to work across dozens of applications.

If you’re tired of replacing lightweight geotextiles every few years, or dealing with project delays from fabric failures, 600gsm is the solution. It’s an investment that pays off in the long run, with fewer repairs, less maintenance, and projects that stand the test of time.

Reach out to our team if you want to see samples, get help calculating how much fabric your project needs, or hear more about our installation best practices. We’ve worked on hundreds of large-scale jobs with 600gsm non woven fabric, and we’re happy to share our expertise.