4800g Geosynthetic Clay Liner

1.Excellent Sealing Performance – Provides low permeability for effective containment.

2.High Swelling Capacity – Bentonite core expands to form a strong waterproof barrier.

3.Easy and Fast Installation – Reduces construction time and labor costs.

4.Strong Shear Strength – Ensures stability on slopes and uneven surfaces.

5.Durable and Long-lasting – Resistant to chemical erosion and aging.

6.Environmentally Friendly – Natural clay material with minimal environmental impact.

4800g Geosynthetic Clay Liner

In the realm of modern environmental engineering and geotechnical construction, Geosynthetic Clay Liners (GCLs) have emerged as a vital material for lining systems due to their unique properties and versatility. Among the various types available, the 4800g GCL stands out for its enhanced durability, higher bentonite content, and broader range of applications. This article explores the characteristics, benefits, applications, and technological advantages of the 4800g Geosynthetic Clay Liner, with a spotlight on Haoyang Environmental Co., Ltd, a trusted manufacturer and innovator in this field.

Product Overview

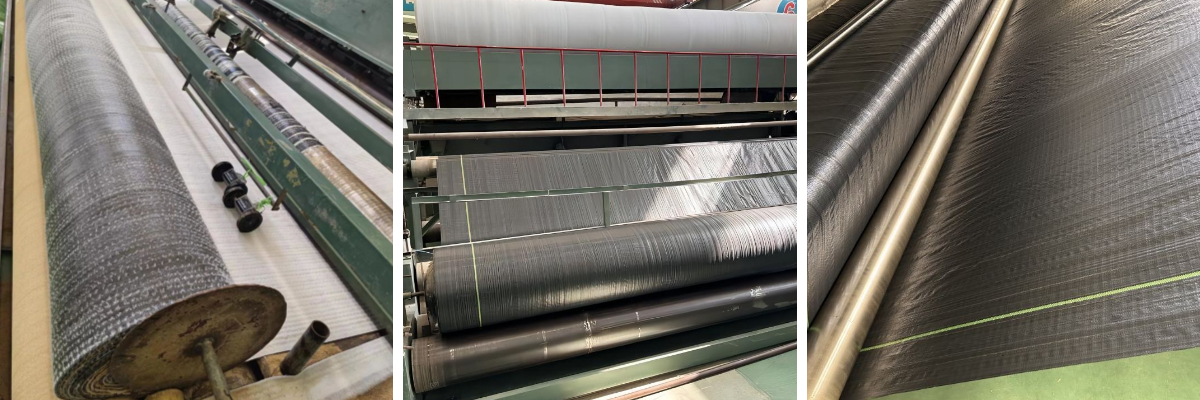

The 4800g Geosynthetic Clay Liner is a reinforced barrier system primarily composed of a high-quality sodium bentonite core encapsulated between layers of geotextiles. These layers are either needle-punched or thermally bonded to improve internal shear strength and integrity. Weighing 4800 grams per square meter, this product contains a significant amount of bentonite, which enhances its ability to form a low-permeability seal when hydrated.

This type of GCL is designed to meet the requirements of more demanding applications, particularly where higher mechanical strength and longer design life are necessary. The dense structure ensures better containment of liquids, gases, and waste materials compared to standard GCLs.

Key Performance Features

The performance of the 4800g GCL is defined by several measurable and practical attributes that make it a superior lining solution:

Low Hydraulic Conductivity: Once hydrated, the bentonite layer forms a gel-like seal with permeability values as low as 1.0 x 10^-11 m/s, making it highly effective in preventing fluid migration.

Strong Internal Shear Resistance: Needle-punched reinforcement allows the liner to maintain stability even on slopes and in vertical applications, minimizing the risk of slippage or delamination.

Chemical Resistance: The naturally occurring bentonite is resistant to a wide range of contaminants, making the liner suitable for landfill, mining, and wastewater treatment projects.

Thermal Stability: It can withstand temperature fluctuations without losing its sealing function, which is crucial for applications in harsh climates.

Self-Healing Capability: The swelling behavior of bentonite enables the liner to self-seal minor punctures and overlaps, maintaining its integrity over time.

Advantages

The 4800g GCL offers a multitude of benefits to project developers, engineers, and contractors. These advantages are not just performance-based but also relate to installation, lifecycle cost, and environmental considerations:

Efficient Installation: Compared to compacted clay layers or thick polymer liners, the GCL is lighter and easier to deploy, reducing labor time and equipment needs on site.

Space-saving: Its thin profile makes it ideal for projects where space is limited or where maximizing containment capacity is a priority.

Cost-effective: Reduced installation time and long-term performance lead to lower total project costs.

Sustainability: Made from natural materials, the liner has minimal environmental impact and contributes to sustainable construction practices.

Versatility: It can be used in combination with HDPE geomembranes for composite lining systems, enhancing overall containment effectiveness.

Applications

The robust performance of the 4800g Geosynthetic Clay Liner makes it suitable for a wide range of civil engineering and environmental protection projects. Common application areas include:

Municipal and Industrial Landfills: Used as part of bottom liners and capping systems to prevent leachate contamination.

Mining Sites: Provides barrier protection in tailings ponds, heap leach pads, and containment reservoirs.

Water Reservoirs and Canals: Ensures watertight containment in irrigation and drinking water systems.

Wastewater Treatment Facilities: Applied in lagoons and holding basins to prevent seepage and soil contamination.

Tunnel and Underground Construction: Serves as a waterproofing layer in subgrade structures and basements.

Its adaptability makes it a favored choice for both new construction and remediation projects where containment reliability is essential.

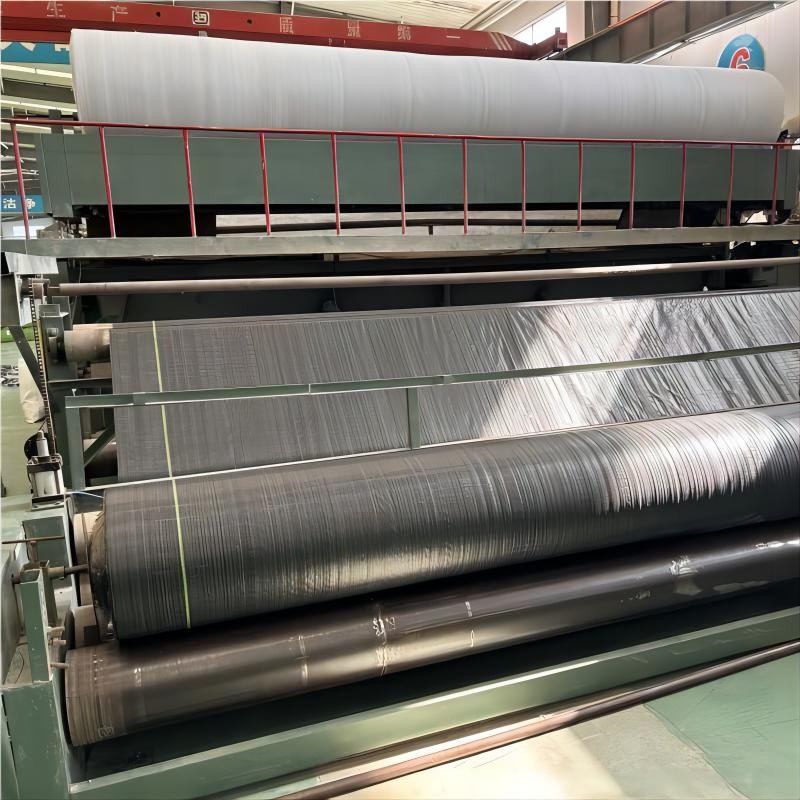

Haoyang’s Manufacturing Excellence

As a globally recognized source factory, Haoyang Environmental Co., Ltd specializes in the production of high-performance geosynthetic materials, including the 4800g Geosynthetic Clay Liner. With a commitment to quality and innovation, Haoyang distinguishes itself through:

Use of 100% Virgin Raw Materials: Ensuring product purity and consistent performance across batches.

Advanced Production Lines: Fully automated systems allow for precise control over fabric layering, bentonite density, and bonding strength.

Rigorous Quality Control: Every batch undergoes mechanical and hydraulic testing to verify compliance with international standards.

Global Project Experience: Haoyang’s GCL products have been successfully deployed in government and private sector projects across Asia, Africa, the Middle East, and South America.

Technical Support: The company provides comprehensive guidance on product selection, installation methods, and post-construction inspection to ensure optimal results for clients.

Through continuous R&D and customer-focused solutions, Haoyang remains at the forefront of geosynthetic innovation, making the 4800g GCL a product you can trust for mission-critical applications.

NO. | item | technical standard | results | |

1 | mass per unit area of GCL (g/㎡) | ≥4800 | 5424 | |

2 | mass per unit area of sodium bentonite(g/㎡) | / | 5088 | |

3 | expansion index of sodium bentonite(ml/2g) | ≥24 | 24 | |

4 | tensile strength(N/100mm) | in the longitudinal direction | ≥600 | 1156 |

5 | elongation at maximum load(%) | ≥10 | 17 | |

6 | peel strength(N/100mm) | ≥40 | 86.4 | |

7 | vertical permeability coefficient(m/s) | ≤5.0x10-11 | 4x10-11 | |

8 | filtration loss(ml) | ≤18 | 16.4 | |

9 | thickness(mm) | ≥6 | 8.06 | |

10 | weight per unit area of non-woven fabric(g/㎡) | ≥200 | 204 | |

11 | tensile strength | lateral direction. | ≥10 | 10.9 |

longitudinal direction | ≥10 | 12.8 | ||

12 | elongation at maximum load(%) | lateral direction. | 40-80 | 60 |

longitudinal direction | 40-80 | 56 | ||

13 | weight per unit area of woven fabric(g/㎡) | ≥110 | 114 | |

14 | tensile strength | lateral direction. | ≥15 | 20.6 |

longitudinal direction | ≥20 | 21.5 | ||

15 | elongation at maximum load(%) | lateral direction. | ≤28 | 17 |

longitudinal direction | ≤28 | 21 | ||

The 4800g Geosynthetic Clay Liner exemplifies the evolution of containment technology in civil and environmental engineering. Its blend of high bentonite content, excellent sealing properties, ease of installation, and versatility makes it an indispensable material in modern infrastructure. Backed by the manufacturing excellence of Haoyang Environmental Co., Ltd, this GCL offers not only superior performance but also peace of mind in even the most challenging conditions.

Whether for landfill capping, mining site containment, or municipal water projects, the 4800g GCL delivers reliable, sustainable, and cost-effective protection.