Fiberglass Geogrid

1.High Tensile Strength – Excellent reinforcement for asphalt and soil stabilization.

2.Low Creep – Maintains structural integrity under long-term load.

3.Thermal Stability – Performs well under high temperatures, ideal for pavement reinforcement.

4.Corrosion Resistance – Durable in harsh environments, including acidic and alkaline soils.

5.Easy Installation – Lightweight and flexible, reducing labor and time costs.

6.Improves Pavement Life – Effectively prevents cracking and rutting, extending road service life.

Fiberglass Geogrid

In the modern construction industry, the demand for durable, cost-effective, and environmentally sustainable materials is higher than ever. Among various geosynthetic materials, Fiberglass Geogrid has emerged as a key solution in reinforcing asphalt pavements, roadbeds, and soil structures. This innovative product significantly improves the performance and longevity of infrastructure, helping engineers and project managers meet the increasing challenges posed by heavy traffic, extreme climates, and unstable soil conditions.

What is Fiberglass Geogrid?

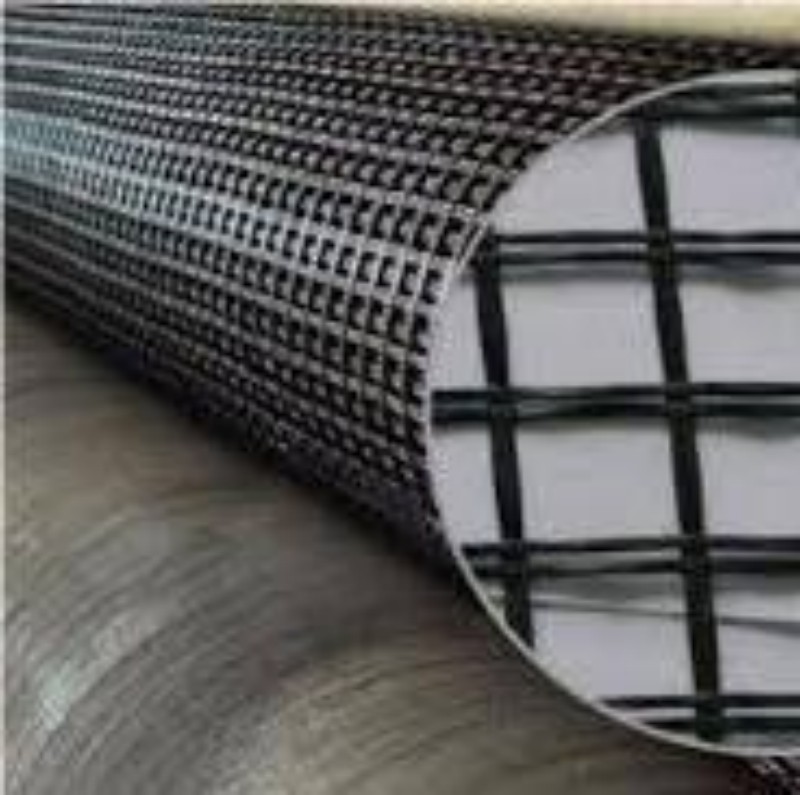

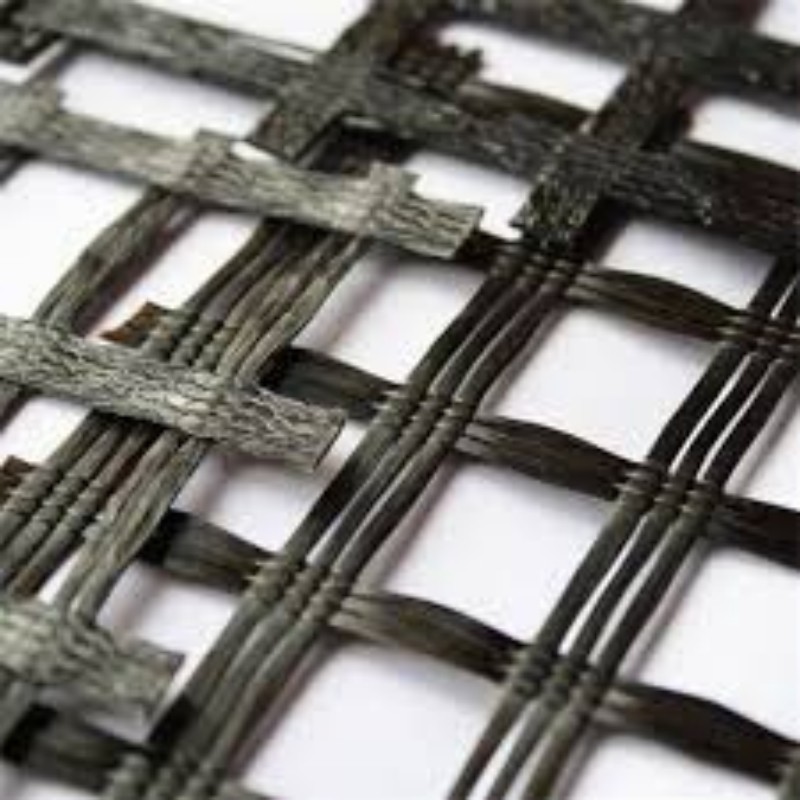

Fiberglass Geogrid is a type of geosynthetic material made from high-strength alkali-free glass fibers. These fibers are coated with a bitumen or polymer-based material to enhance their chemical resistance and bonding with asphalt or soil. The resulting grid structure features high tensile strength in both longitudinal and transverse directions, which makes it ideal for load distribution and crack resistance in flexible pavement systems.

Key Advantages of Fiberglass Geogrid

1. High Tensile Strength and Low Elongation

One of the most notable features of fiberglass geogrid is its exceptional tensile strength with minimal elongation. Unlike traditional reinforcement materials such as steel or plastic, fiberglass geogrid maintains high tensile strength without stretching under load, ensuring structural stability and effective stress distribution.

2. Excellent Thermal Stability

Fiberglass geogrid performs well in high-temperature environments, making it an excellent choice for asphalt reinforcement. It maintains its mechanical properties even when exposed to extreme heat during paving, which helps prevent deformation and fatigue cracking in road surfaces.

3. Corrosion and Chemical Resistance

Due to the inorganic nature of glass fibers, fiberglass geogrids are inherently resistant to corrosion, alkalis, and acids. This makes them suitable for a wide range of environments, including areas with saline soil, industrial pollution, or aggressive underground conditions.

4. Fatigue and Crack Resistance

When used in pavement systems, fiberglass geogrid significantly reduces reflective and fatigue cracking by absorbing and distributing tensile stress caused by repeated traffic loads. This helps extend the life of roadways and reduces the frequency and cost of maintenance.

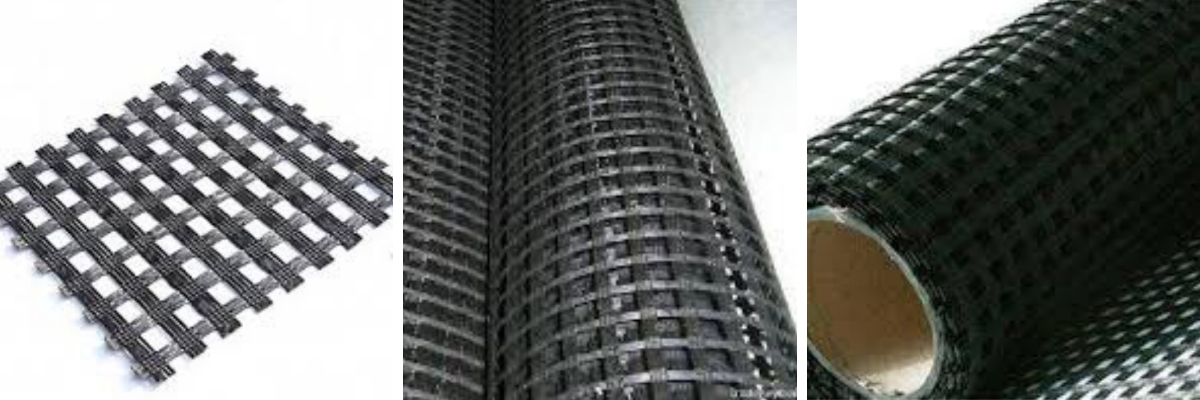

5. Lightweight and Easy Installation

The lightweight nature of fiberglass geogrid simplifies transportation, handling, and installation on-site. It can be quickly unrolled and placed, saving labor and machinery costs while reducing overall construction time.

6. Environmentally Friendly

Compared to some traditional reinforcement methods, fiberglass geogrid has a lower carbon footprint during production and contributes to sustainable construction practices by reducing the need for frequent repairs and material replacement.

Applications of Fiberglass Geogrid

Fiberglass geogrid is used extensively in various infrastructure projects, including:

1.Asphalt pavement reinforcement in highways, city roads, and airport runways

2.Roadbed stabilization for new construction and rehabilitation projects

3.Railway ballast and subgrade reinforcement

4.Slope and embankment stabilization

5.Retaining wall and foundation reinforcement

Its versatility makes it an ideal solution for both new projects and rehabilitation of existing infrastructure.

Haoyang Environmental Co., Ltd.: Your Trusted Source for Fiberglass Geogrid

As one of the leading manufacturers of geosynthetic products in China, Haoyang Environmental Co., Ltd. has established a strong reputation for producing high-quality fiberglass geogrid and other geotechnical materials. With a commitment to innovation, reliability, and customer satisfaction, Haoyang has become a preferred supplier for government infrastructure projects, private contractors, and international clients.

Why Choose Haoyang?

1. 100% Virgin Raw Materials

Haoyang ensures product consistency and superior performance by using only virgin raw materials in its manufacturing process. This results in fiberglass geogrids with stable physical and mechanical properties.

2. Advanced Production Technology

With modern equipment and a rigorous quality control system, Haoyang's production facilities are capable of delivering high-strength geogrids that meet international standards such as ASTM, ISO, and CE.

3. Customized Solutions

Haoyang provides tailor-made geogrid solutions to meet the specific requirements of different engineering applications. Whether it's reinforcement strength, mesh size, or surface coating, products can be adjusted according to project needs.

4. Export Experience and Global Recognition

Haoyang's fiberglass geogrid products have been successfully exported to more than 50 countries, including markets in Southeast Asia, the Middle East, Europe, and Africa. The company has received positive feedback for its product quality, timely delivery, and excellent after-sales support.

5. Technical Support and On-Site Guidance

Beyond manufacturing, Haoyang offers technical consultation and on-site support to help clients with installation and application challenges. Their engineering team works closely with clients to ensure optimal performance and cost efficiency.

Case Studies and Real-World Applications

Haoyang's fiberglass geogrid has been used in numerous large-scale infrastructure projects across China and internationally. Examples include:

1.High-speed rail projects in central China where soil stabilization and vibration resistance were critical

2.Airport runway rehabilitation in Southeast Asia, where thermal stability and crack resistance were vital

3.Mountain highway constructions in Central Asia, requiring slope reinforcement and erosion control

These successful implementations highlight the adaptability and effectiveness of fiberglass geogrid in diverse geotechnical scenarios.

Future Outlook

With increasing global investment in infrastructure, especially in the developing world, the demand for reliable geotechnical solutions is expected to grow rapidly. Fiberglass geogrid is poised to play an even greater role in ensuring the durability, safety, and sustainability of roads, bridges, and foundations.

Haoyang Environmental Co., Ltd. is continuously investing in research and development to further enhance the performance of fiberglass geogrid and expand its applications. Innovations such as composite geogrids, multi-axial reinforcements, and eco-friendly coatings are already in the pipeline.

Item | Description |

Product Name | Fiberglass Geogrid |

Material | Alkali-free fiberglass yarn with polymer or bitumen coating |

Mesh Type | Biaxial grid (equal tensile strength in MD and TD) |

Tensile Strength | 25–200 kN/m (customizable) |

Elongation at Break | < 3% |

Coating Options | Bitumen / PVC / Polymer |

Roll Width | 1.0 m – 6.0 m (standard: 3.95 m) |

Roll Length | 50 m – 100 m (customizable) |

Application Areas | Asphalt reinforcement, roadbed stabilization, slope protection, retaining walls |

Thermal Stability | Excellent resistance to high paving temperatures |

Chemical Resistance | Strong resistance to acid, alkali, corrosion |

Installation | Easy to install; compatible with paving equipment |

Certifications | ISO 9001, CE, ASTM |

Raw Materials | 100% virgin fiberglass + high-quality coating resins |

Packaging | Wrapped with PE film and woven bags or customized |

Lead Time | 7–15 working days (depending on quantity) |

Export Markets | Southeast Asia, Middle East, Europe, Africa, South America |

Supplier Highlights | Direct factory, R&D support, OEM available, 24/7 technical assistance |

Fiberglass Geogrid is more than just a reinforcement material—it’s a key enabler of long-lasting, cost-effective, and resilient infrastructure. Its technical advantages, coupled with ease of use and environmental benefits, make it an indispensable part of modern civil engineering projects.

For those seeking a trusted partner and top-tier product, Haoyang Environmental Co., Ltd. offers the perfect combination of quality, innovation, and customer-focused service. Whether you’re building roads, railways, or retaining walls, Haoyang’s fiberglass geogrid ensures that your structures stand the test of time.