Production Lines Equipped with "Smart Brains"

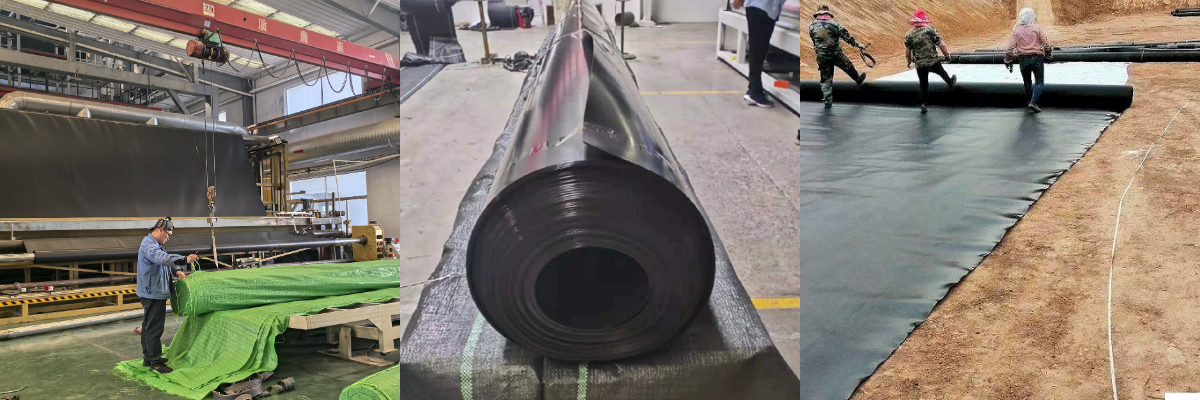

On November 17th, in the geomembrane production workshop of Yucheng Haoyang Environmental Protection Co., Ltd., machines roared, robotic arms precisely grabbed raw materials, and automated production lines operated at high speed. From feeding, proportioning, and automatic weighing to melt extrusion and blow molding, the entire process was completed seamlessly. Rolls of geomembrane rolled off the production line, ready to be shipped to domestic and international markets. "In the first three quarters of this year, the company's export volume reached 200 million yuan, a year-on-year increase of 50%. Behind this is our continuous investment in digital transformation," said Li Hongzhen, the company's technical director.

Haoyang Environmental Protection has been deeply involved in the geosynthetic materials field for 18 years. It is the first geosynthetic materials production enterprise in Shandong Province to possess "special anti-seepage qualification" and is also a core enterprise in China's geosynthetic materials export. Relying on more than 20 automated production lines, the company has an annual production capacity of 300,000 tons, with products covering more than 20 types in four major categories, including geomembranes and geotextiles. These products are exported to more than 70 countries and regions worldwide, making it a leader in the industry in terms of technology and production capacity. However, the geosynthetic materials industry was often labeled as "clumsy and inefficient" in the past. The inefficiency of manual material feeding, uneven mixing affecting quality, and packaging speed lagging behind production capacity once constrained the company's development. Now, stepping into Haoyang Environment's workshop, from raw material feeding to finished product warehousing, the entire process is digitally controlled, and the traditional manufacturing model is being replaced by a smart and green new production method.

"In the past, the material feeding process required at least five or six people working together. Forklifts were used to move bags of raw materials, which was not only inefficient but also posed safety hazards," Li Hongzhen explained, pointing to the robotic automatic feeding system. "Once the parameters are set, it can achieve 24-hour automatic feeding, reducing manpower to zero and increasing efficiency by about 15%."

"The Fourth Plenary Session of the 20th CPC Central Committee proposed to optimize and upgrade traditional industries. Implementing the spirit of the plenary session, promoting technological transformation and upgrading, and facilitating digital transformation are key approaches," Li Hongzhen said. He added that previously, the company had long adopted an extensive production model with low levels of digitalization and relatively outdated production lines, making it difficult to meet the market's demand for high-quality products. In 2021, the company launched its digital transformation, introducing Inspur Group's Digital Intelligent Manufacturing System (MES) and Digital Twin Platform: the former equips the production workshop with a "smart brain," while the latter, through simulation, process optimization, remote diagnostics, and predictive maintenance, builds an adaptive production and innovation service platform. Stepping into the workshop's central control area, data on multiple screens jumps around in real time, clearly displaying indicators such as raw material inventory, output quantity, product specifications, equipment operating parameters, and total workload analysis. "The network connectivity rate of key equipment has reached 100%, with data collected and updated in real time throughout the entire process, allowing managers to monitor production dynamics at any time," said Li Hongzhen. He added that this system acts like a "new engine," driving an overall production efficiency increase of 20% and a reduction in labor costs of nearly 15%. The system also assigns a unique identification code to each product, enabling full-process data tracking from raw material procurement, production processing, quality testing, and logistics distribution, ensuring precise and traceable production control for high-end products such as sprayed geomembranes. The changes brought about by digital transformation go far beyond this. Addressing industry pain points such as slow and uneven mixing in production, the company introduced a fully automated intelligent batching system. Through digital algorithms, it precisely controls raw material ratios, improving batching efficiency by approximately 50% and ensuring 100% batch stability. In the packaging stage, fully automated intelligent wrapping machines replace the traditional manual bagging and sewing methods, increasing packaging speed by more than three times and completely solving the problem of "fast front-end production, slow back-end packaging." From "clumsy and inefficient" to "high-precision and sophisticated," Haoyang Environment's transformation demonstrates the empowering effect of digital technology on traditional industries. Today, digitalization has permeated all aspects of production, management, and service. "The Fourth Plenary Session of the 20th CPC Central Committee set the direction and clarified the path for the development of intelligent manufacturing, and put forward higher requirements for the transformation and upgrading of traditional industries," said Zhao Kuili, Chairman of the company. He added that the company is accelerating its digital transformation under the guidance of the spirit of the plenary session. Currently, the newly built digital office building, digital exhibition hall, and nationally accredited laboratory are in their final stages of completion and are expected to be put into use before the end of the year. Upon completion, the building will integrate core functions such as intelligent production scheduling, digital display, quality management, data traceability, and collaborative office work, achieving full-chain digital control from raw material procurement to finished product delivery, and propelling the company's digital transformation to a new level.