"Hao" product - Specialized Geomembrane for Hydrometallurgy

Geomembrane for hydrometallurgy

1.Corrosion by strong oxidizing media

Long-term immersion in strong oxidizing media such as hydrogen peroxide and ozone water will cause the anti-oxidant in ordinary geotextiles to be rapidly depleted, leading to chemical corrosion and perforation, and a high risk of failure in seepage prevention. The oxidation-induced time is shortened by more than 50%, and the material lifespan is only 1- 2 years.

2. Challenges in highly corrosive environments

Wet smelting involves high-concentration acids, bases, and heavy metal solutions. Traditional materials are prone to corrosion and aging, leading to leakage risks. Leakage can cause environmental pollution (soil and groundwater contamination), production halts, and even face hefty environmental penalties.

3. Poor adaptability to extreme conditions

Extreme conditions such as high temperature (with some of the molten liquid exceeding 60℃), high pressure, and mechanical wear make ordinary geotextile membranes prone to deformation and rupture.

4. Hidden costs are high.

Leakage leads to the loss of precious metals and a sharp increase in ecological restoration costs, with significant losses resulting from a single incident.

Features of Geomembranes for Hydrometallurgical Special Use

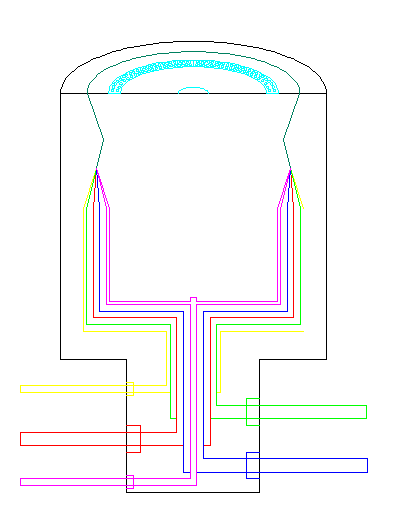

Five-layer co-extrusion blow molding process

1.Superior resistance to chemical corrosion

Resistant to strong oxidation corrosion formula, with a 3-fold enhancement in the ability to resist dual hydrogen peroxide-ozone strong oxidation and the combined corrosive effects of high-concentration acids, bases, and salts.

2. Adaptability to Extreme Conditions

Five-layer co-extrusion technology combined with nano-functional layer enhancement design, with a design lifespan of 5-8 years, reducing maintenance frequency by 60%, and meeting the requirements of the wet smelting market.

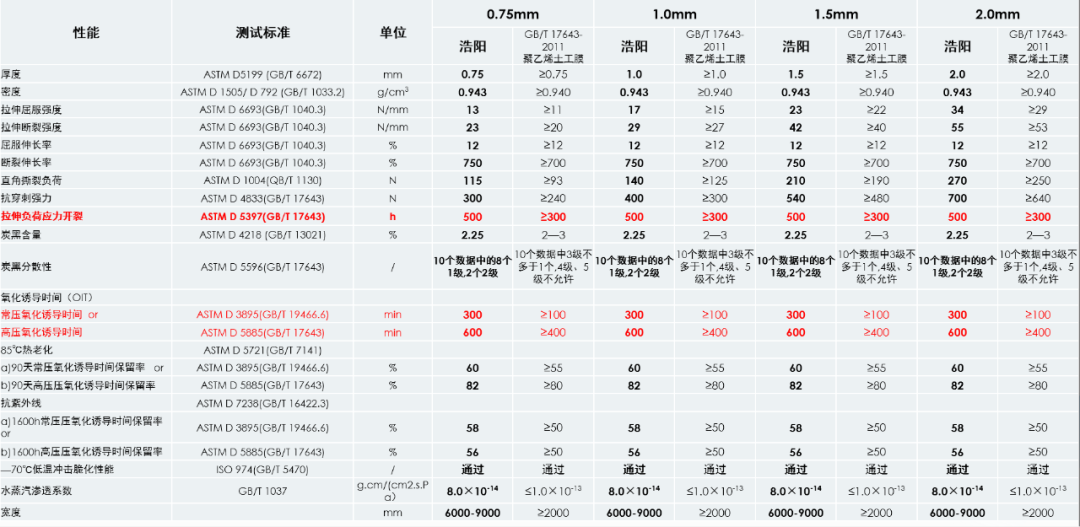

Technical indicators