"Hao" Product - Geomembrane Specifically Designed For Hydrometallurgy

Special geomembrane for hydrometallurgy

Develop innovative products

Pain points of conventional geomembrane applications

Corrosion by strong oxidizing media

Long-term immersion in strong oxidizing media such as hydrogen peroxide and ozone water leads to the rapid consumption of antioxidants in ordinary geomembranes, resulting in chemical corrosion perforation and a high risk of anti-seepage failure. The oxidation induction time is shortened by more than 50%, and the material life is only 1-2 years.

Challenges in highly corrosive environments

Hydrometallurgy involves high-concentration acid, alkali and heavy metal solutions. Traditional materials are prone to corrosion and aging, leading to leakage risks. Leakage can cause environmental pollution (soil/groundwater pollution), production halts, and even face heavy environmental protection penalties.

Poor adaptability to extreme working conditions

Under extreme conditions such as high temperatures (with some smelting liquids exceeding 60℃), high pressure, and mechanical wear, ordinary geomembranes are prone to deformation and rupture.

The implicit cost is high.

Leakage leads to the loss of precious metals and a sharp increase in ecological restoration costs, resulting in significant losses from a single accident.

filtrate leakage

Characteristics of geosynthetic membranes for hydrometallurgy

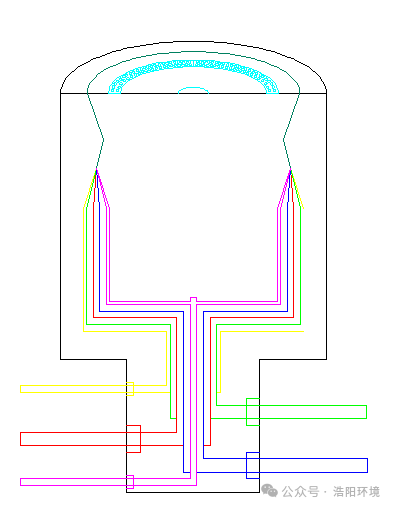

Five-layer co-extrusion blow molding process

01

Super strong chemical corrosion resistance

The formula resistant to strong oxidation and corrosion enhances the resistance to strong oxidation by hydrogen peroxide and ozone as well as the synergistic corrosion by high-concentration acids, alkalis, salts and other media by three times.

02

Adaptability to extreme working conditions

Five-layer co-extrusion process + nano-functional layer enhanced design, with a design life of 5 to 8 years, reduces maintenance frequency by 60%, and is suitable for the demand market of hydrometallurgy.

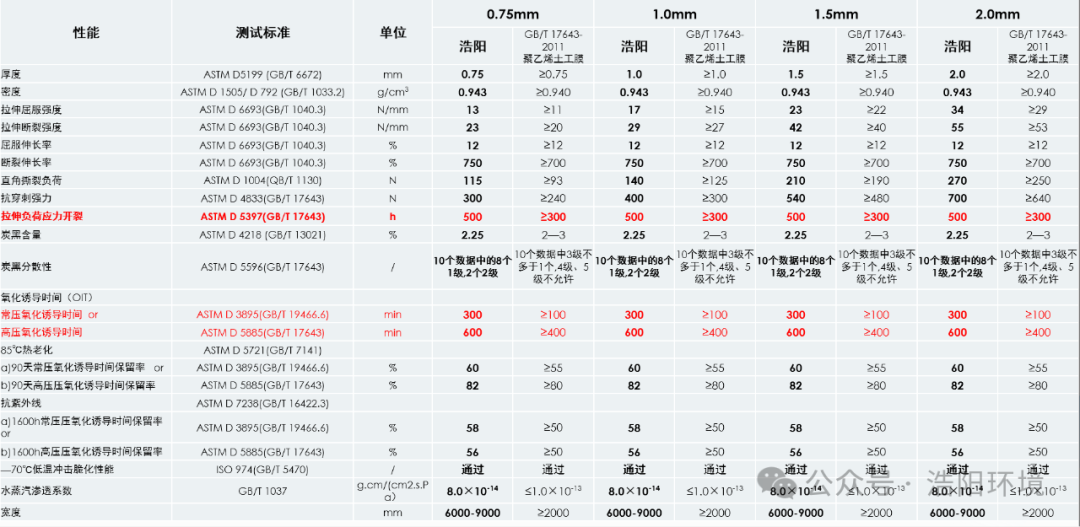

Technical indicators