"Hao" Product - Anti-clogging Drainage Net

Application Advantages

Poor Corrosion Resistance: Conventional drainage nets have poor acid and alkali resistance and are easily hydrolyzed. Used in leachate drainage systems such as tailings ponds, red mud dumps, and hazardous waste landfills, they are susceptible to acid and alkali corrosion, leading to failure.

Pore Structure: Conventional drainage nets are loose and have poor tension. After landfill, fine particles from the landfill penetrate the pores and mesh core, causing blockage of the drainage channels.

The mesh core has poor compressive strength. Conventional drainage nets have large mesh sizes and an unstable core structure, resulting in poor compressive strength. Under the weight of the landfill, they easily deform, causing the drainage channels to shrink or close.

Core advantages of products

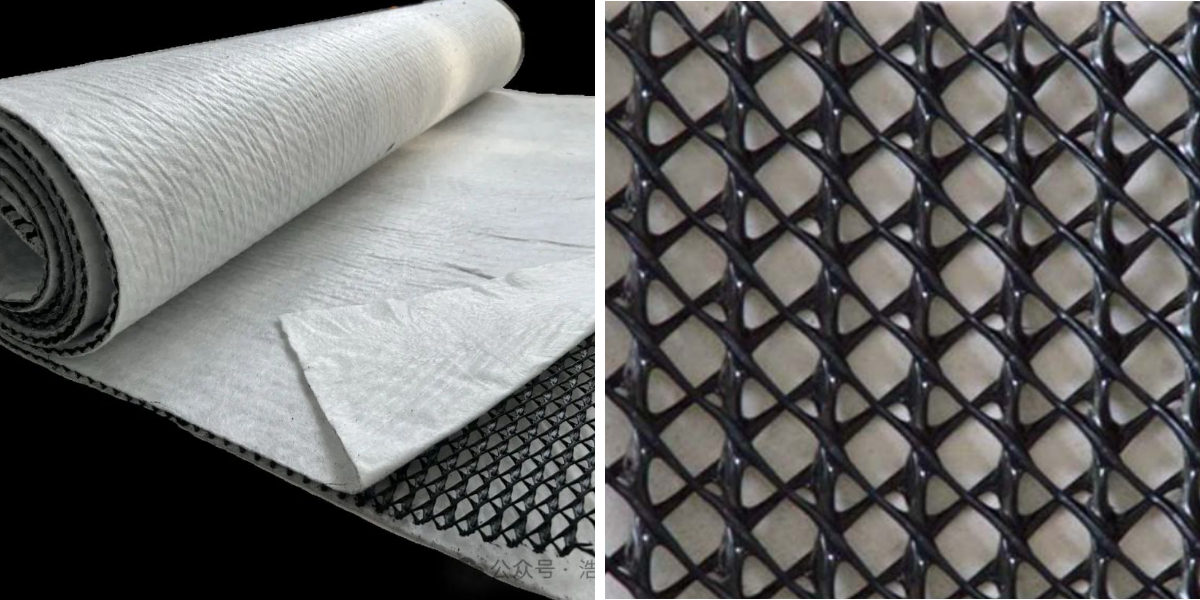

1.Composite Fabric Anti-clogging Design:

A gradient filtration mechanism: Geotextiles offer high modulus, high tension, and anti-clogging properties. The surface pore size is ≤0.15 mm, intercepting sediment while maintaining a water permeability of ≥5.0 × 10-2 m2/s.

2. The high-compression drainage net core

Three-dimensional rib structure Compressive strength ≥830 kPa (ASTM D6364), deformation <10%. Water conductivity retention rate 100h >80%.

3. Full Chemical Resistance:

Tensile strength retention >90% after 30-day immersion in 10% sulfuric acid/NaOH (ASTM D7238).

Applicable Environment: pH 2-12.

Product Applications

Civil Engineering and Infrastructure Construction:

Railway Roadbed Drainage: In soft or frozen soil areas, the drainage network's anti-clogging structure prevents clogging with fine soil particles, maintaining long-term drainage efficiency and preventing roadbed subsidence caused by water accumulation. Its chemical resistance resists de-icing agents and underground salt erosion, extending road life.

Tunnel Engineering: Tunnel seepage often contains sediment, making traditional drainage pipes prone to clogging. The anti-clogging drainage network's multi-layer gradient filtration design traps impurities while releasing water pressure through structural elasticity. Combined with the high compressive strength of the mesh core, it adapts to complex tunnel load environments.

Environmental Engineering:

Landfill Leachate Drainage: Leachate contains high concentrations of organic matter and acidic substances, making conventional drainage materials susceptible to corrosion and failure. Anti-clogging drainage nets utilize acid- and alkali-resistant materials to resist chemical attack, while their anti-clogging structure prevents sludge adhesion, ensuring the long-term, stable operation of leachate collection systems.

Contaminated soil containment projects: Drainage nets are embedded within vertical anti-seepage walls, leveraging their efficient water conduction capabilities to rapidly drain contaminated groundwater and prevent the spread of pollutants.

Water Conservancy and Flood Control Projects:

Seawall/Riverbank Protection: Long-term exposure to salty seawater or sediment can easily corrode or clog traditional drainage materials. The acid-, alkali-, and salt spray-resistant properties of anti-clogging drainage nets withstand harsh environments, reducing frequent replacement costs.

Reservoir and Dam Drainage: Earth-rockfill dams require continuous drainage to lower pore water pressure. Anti-clogging designs prevent fine soil particles from entering the drainage layer, reducing filter layer construction costs and minimizing the risk of dam failure.

Industry and Energy:

Petrochemical Tank Area Anti-seepage Drainage: Leaked oil or chemicals are highly corrosive. The chemically inert material of the drainage net is resistant to oil, acid, and alkali corrosion. Combined with the drainage system, leaked liquids can be quickly collected, preventing environmental pollution and lowering incident response costs.

Mine tailings pond drainage: Tailings slurry is extremely fine-grained and easily clogs drainage facilities. The nonwoven composite layer of the anti-clogging drainage net provides fine filtration. Its high hydraulic conductivity also accelerates tailings consolidation, reducing the risk of dam failure and saving on reservoir capacity expansion costs.