Heqing Beiya Mining Co., Ltd. Dali Dasha Tailings Reservoir Expansion Project

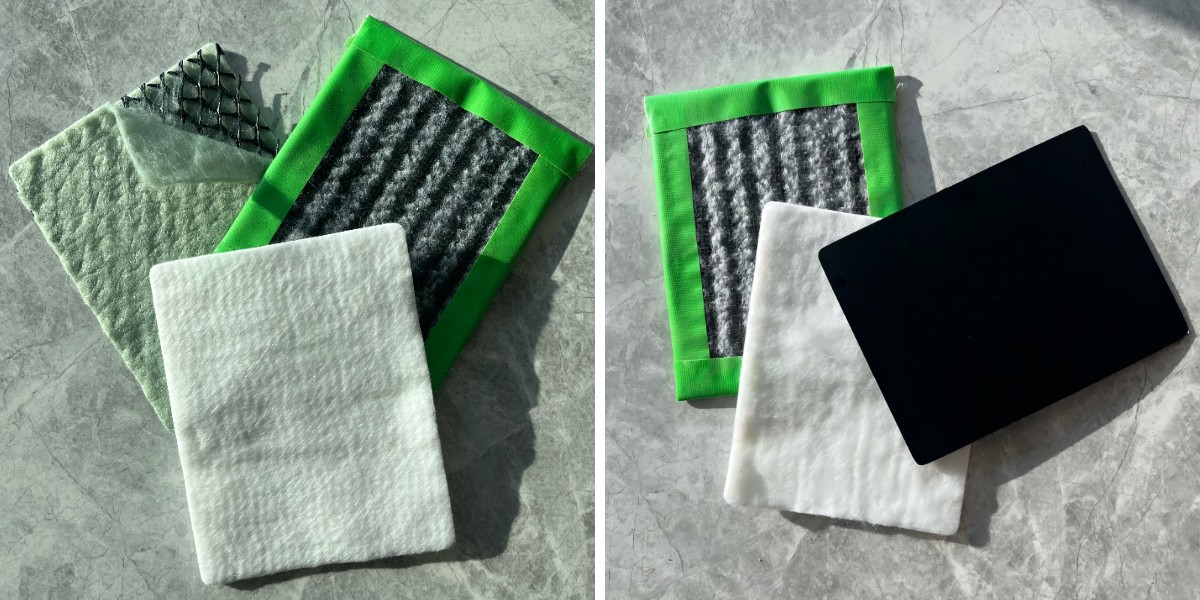

The capacity of this project is approximately 17 million cubic meters, with a service life of 12 years, employing a composite impermeable system. Our company's provided products and engineering construction services ensure the long-term stability of the impermeable system, effectively preventing tailings leachate from polluting the surrounding environment. The cyanide-containing tailings are classified as hazardous waste. In accordance with the national requirements for the secure landfill of hazardous waste, a double artificial lining impermeable system is adopted for the tailings reservoir. Given the characteristics of this project, the impermeable system of the tailings reservoir incorporates products manufactured by our company, including HDPE geosynthetic membranes, continuous filament spunbond needle-punched geotextiles, and biaxial stretched geogrids.

The Yezhe Village Phosphogypsum Residue Repository, located in Laohelongou, Gongshan Town, Xundian Hui and Yi Autonomous County, northern Kunming City, Yunnan Province, is a project undertaken by China National Chemical Corporation Yunnan Co., Ltd. The first phase is a Class III tailings pond with an effective capacity of 8.3427 million cubic meters, designed to meet the production and storage needs of the factory for 10 years. The slurry pipeline and return water pipeline each span approximately 20 kilometers. The anti-seepage system for the reservoir bottom is constructed from the bottom up as follows: foundation leveling and appropriate compaction, compacted clay, geogrid, 4800g/m² GCL (Geosynthetic Clay Liner) bentonite waterproof blanket, 6.3mm three-dimensional composite drainage net, 1.5mm HDPE single rough surface impermeable membrane, and 600g/m² geotextile. The anti-seepage system for the reservoir slope is constructed from the bottom up as follows: foundation leveling, 4800g/m² GCL bentonite waterproof blanket, 1.5mm HDPE single rough surface impermeable membrane, with partial use of 600g/m² geotextile.

The project is located in a valley with a long and narrow topography, featuring steep slopes on both sides. The design structure of the bottom and slope anti-seepage system from bottom to top is as follows:

1, Bentonite Waterproof Blanket: Effectively prevents the harm caused by uneven settlement to the HDPE geomembrane and serves as an auxiliary measure for anti-seepage and isolation.

2, Single Rough Surface HDPE Geomembrane: Overcomes challenges posed by adverse geological conditions, meeting project requirements. With excellent mechanical properties, good elongation, and stable chemical performance, it enhances anti-slip performance and construction quality.

3, Continuous Filament Spunbond Needle-Punched Geotextile: Permeable while preventing damage to the membrane from sharp objects or sudden uneven loading. The product's performance and construction quality well meet the practical requirements of the project."

Seepage Barrier: Acts as a highly effective barrier to prevent seepage and leakage of liquids within the project site.

Functions of the GCL:

Containment: Contains and isolates any potential contaminants or hazardous materials, preventing them from spreading into the surrounding environment.

Stability Enhancement: Enhances the stability of the project area by providing a secure and impermeable layer, particularly important in challenging terrains.

Structural Support: Provides additional support to the overall structure, contributing to the integrity and durability of the project.

Environmental Protection: Safeguards the environment by preventing the migration of harmful substances, aligning with best practices in environmental protection.

The funtions of 1.5mm Black Single Textured HDPE Geomembrane in this project:

1), Seepage Prevention: Serves as a robust barrier to prevent the seepage or leakage of liquids, ensuring containment within the designated area.

2), Geomembrane Integrity: Enhances the overall integrity of the project by providing a durable and impermeable layer.

3), Durability: With a thickness of 1.5mm, the geomembrane offers durability and resilience against environmental factors, contributing to the long-term effectiveness of the project

3, 600g/m² Filament nonwoven needle punched geofabrics

Functions:

Separation: Provides a separation layer between different soil materials or between soil and other components, preventing mixing and maintaining distinct layers.

Filtration: Acts as a filtration barrier, allowing water to pass through while preventing the migration of fine soil particles, ensuring proper drainage.

Reinforcement: Enhances the mechanical stability of the soil, especially in areas prone to erosion or where additional strength is required.

Erosion Control: Helps control soil erosion by stabilizing the soil surface and preventing the loss of soil particles due to water flow.

FAQ

1. What is the role of geofabrics in the Yezhe Village Phosphogypsum Residue Repository Project?

Geofabrics play a pivotal role in providing various functions, including separation, filtration, reinforcement, and environmental protection. They contribute to the stability and integrity of the repository structure.

2. How do geofabrics contribute to environmental protection in the project?

Geofabrics act as a barrier, preventing the migration of contaminants and hazardous materials, ensuring that the phosphogypsum residue is securely contained, and minimizing the environmental impact.

3. What specific types of geofabrics are used in the project, and why?

The project utilizes geofabrics such as needle-punched nonwovens and GCL (Geosynthetic Clay Liner) bentonite waterproof blankets to provide a multi-functional solution, addressing the unique requirements of the repository's bottom and slope anti-seepage systems.

4. How does geofabric contribute to the stability of the repository in challenging terrains?

Geofabrics, particularly those used in slope anti-seepage, contribute to stability by preventing erosion, enhancing soil stability, and providing structural support in areas with challenging topography.

5. Are geofabrics a sustainable choice for this type of project?

Yes, geofabrics are a sustainable choice as they promote proper waste containment, prevent environmental contamination, and contribute to the long-term stability and effectiveness of the phosphogypsum residue repository.

The funtions of 6.3mm three-dimensional composite drainage net in this project:

Water Drainage: Facilitates efficient drainage of water from the repository, preventing water accumulation and ensuring proper water management within the project site.

Erosion Control: Helps control soil erosion by channeling water away from vulnerable areas, preserving the stability of the repository structure.

Ventilation: Enhances the ventilation of the repository by allowing the movement of air through the three-dimensional structure, reducing the risk of trapped gases and promoting a healthier environment.

Load Distribution: Distributes external loads and pressures evenly across the surface, providing additional support to the underlying layers and contributing to the overall stability of the project.

Protection of Geomembrane: Acts as a protective layer for underlying geomembranes, preventing damage and ensuring the longevity of the anti-seepage system.