Staple Nonwoven Geofabric for Construction Transpotation

In construction, staple nonwoven geofabric is widely employed to enhance soil strength, control erosion, and prevent the loss of fine particles. Its application extends to transportation infrastructure, where it serves as a reliable separator and filter, ensuring the longevity and stability of roads and embankments. The use of staple nonwoven geofabric exemplifies a cost-effective and efficient solution, contributing significantly to the durability and performance of construction and transportation projects.

Geosynthetic products play a crucial role in advancing construction and transportation projects. These specialized materials, including geotextiles, geogrids, and geomembranes, contribute significantly to enhancing the performance and longevity of infrastructure. The integration of geosynthetic products in construction and transportation underscores their importance in creating sustainable, resilient, and high-performing infrastructure systems.

On October 7, 2008, construction commenced on the Beijing-Shijiazhuang High-Speed Rail. On July 25, 2012, the entire rail line was fully laid, and it officially commenced operations on December 26, 2012. The main line of the Beijing-Shijiazhuang High-Speed Rail runs from Dujiakan Line Depot to Shijiazhuang Station, with the Dujiakan Line connecting to Beijing West Station via the Jingxi Connecting Line. The total length of the Beijing-Shijiazhuang High-Speed Rail is 283.672 kilometers, with a design speed of 350 kilometers per hour and an initial operational speed of 300 kilometers per hour. Starting from June 20, 2022, the Beijing-Shijiazhuang section of the Beijing-Guangzhou High-Speed Rail has achieved regular operation at a high standard speed of 350 kilometers per hour.

According to the diverse construction requirements of this project, various products supplied by our company have been utilized in different sections. These include approximately 87,000 square meters of bidirectional stretched geogrid with a specification of 30 kN/m, 67,000 square meters of bidirectional stretched geogrid with a specification of 100 kN/m, as well as geotextiles.

Considering the need to ensure the smooth operation of high-speed trains during high-speed travel, a major challenge in high-speed rail construction is controlling the deformation of the subgrade. This deformation occurs in areas with abrupt changes, such as the transition sections between bridge piers and the subgrade, tunnel exits, and similar locations. Such changes introduce an uneven additional impact force on the fast-moving train wheels, leading to uncomfortable driving conditions. In severe cases, this can reduce the structural lifespan and even pose safety risks. The resulting damage adds to the expensive maintenance and repair costs. Therefore, the use of geosynthetic materials in the transition sections between bridges and roads can effectively overcome this problem. However, it is crucial to maintain high-quality standards for geosynthetic materials to ensure their effectiveness in addressing these issues.

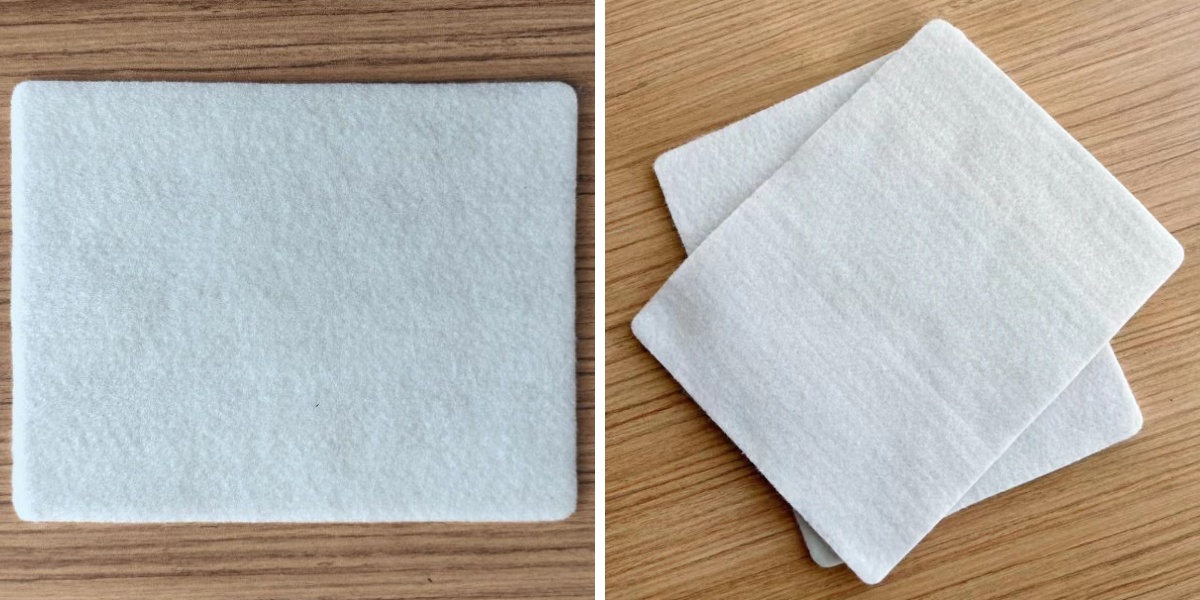

1、Polypropylene Staple Fiber Needle-punched Geotextile: This geotextile is characterized by high strength, excellent elongation properties, large deformation modulus, and resistance to acid, alkali, and corrosion.

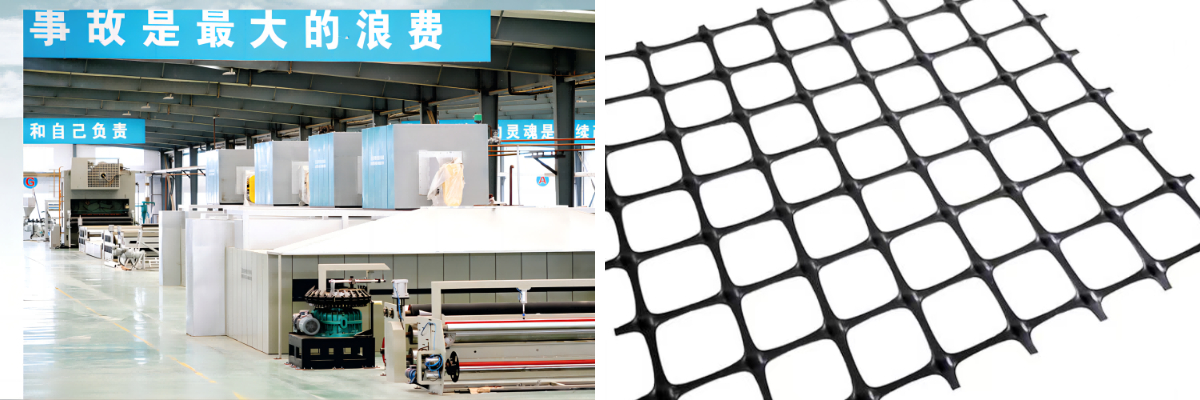

2、Bidirectional Stretched Geogrid: This geogrid boasts high strength, low elongation, and plays a crucial role in reinforcing and strengthening. It effectively reduces the impact of bumps in transition sections, contributing to a smoother ride.

Polypropylene staple fiber needle-punched geotextile is a geotechnical material made by needle-punching short-cut polypropylene fibers. This geotextile exhibits high strength, good elongation properties, a large deformation modulus, and is resistant to acid, alkali, and corrosion.

In railway construction, the role of polypropylene staple fiber needle-punched geotextile includes the following aspects:

1, Soil Reinforcement and Stabilization: The geotextile can be used in railway subgrades to enhance the tensile strength and stability of the soil, slowing down erosion and settlement and ensuring the stability of the subgrade.

2, Erosion Prevention: In areas with steep slopes or prone to soil erosion along the railway route, the geotextile can be used as slope protection material to prevent soil loss and erosion, maintaining the integrity of the subgrade.

3, Isolation Layer: In certain situations, polypropylene staple fiber needle-punched geotextile can function as an isolation layer, preventing the mixing of different types of soil or materials and improving the stability and durability of the engineering structure.

Bidirectional stretched geogrid is a geotechnical material characterized by high strength and low elongation. This material undergoes a process of bidirectional stretching during production, forming a structurally stable grid that evenly distributes loads. In transportation construction, the roles of bidirectional stretched geogrid include the following aspects:

1), Enhancing Soil Bearing Capacity: Bidirectional stretched geogrid effectively reinforces the tensile strength of the soil, improving the soil's bearing capacity. This is particularly crucial in transportation engineering, as it can strengthen the subgrade and support structures, reducing deformation and settlement of the pavement.

2), Slowing Subgrade Settlement: By incorporating bidirectional stretched geogrid into the subgrade, the rate of soil settlement can be effectively slowed down, maintaining the stability of the subgrade and extending its lifespan.

3), Improving Pavement Smoothness: Bidirectional stretched geogrid disperses and transmits loads, reducing the impact of loads on the pavement. This helps improve pavement smoothness and enhances driving comfort.

4), Preventing Lateral Movement of Subgrade: The application of bidirectional stretched geogrid in the subgrade can effectively restrain lateral movement of the soil, preventing subgrade sliding and soil erosion along the alignment.

Haoyang Environmental Co., Ltd. was established on June 6, 2008. The company is located in the National High-tech Industrial Development Zone in Dezhou (Yucheng), Shandong Province. Haoyang Environmental is an international environmental technology and comprehensive service provider, integrating the research and manufacturing of geosynthetic materials, environmental engineering consultation, design, and construction, as well as investment, operation, and comprehensive treatment of solid waste for environmental governance.